You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Grundfos</strong> E-<strong>pumps</strong><br />

10<br />

Standstill heating<br />

Standstill heating is a feature ensuring that even<br />

during standstill periods the motor windings have a<br />

certain minimum temperature.<br />

Purpose and benefits<br />

The purpose of this function is to make the MLE motor<br />

more suitable for outdoor installation. During standstill<br />

periods, there is a need to keep the motor temperature<br />

higher than the ambient temperature to avoid<br />

condensation in and on the motor.<br />

Traditionally this issue has been solved by using an<br />

anti-condensation heater on the stator coil heads.<br />

Now <strong>Grundfos</strong> provides this feature by means of a<br />

special function within the MLE motor and terminal<br />

box.<br />

The MLE motor has standstill heating included.<br />

An external heater on the stator coil is not necessary.<br />

Applications<br />

This function is especially suitable in outdoor<br />

applications and at installation sites with fluctuating<br />

temperatures.<br />

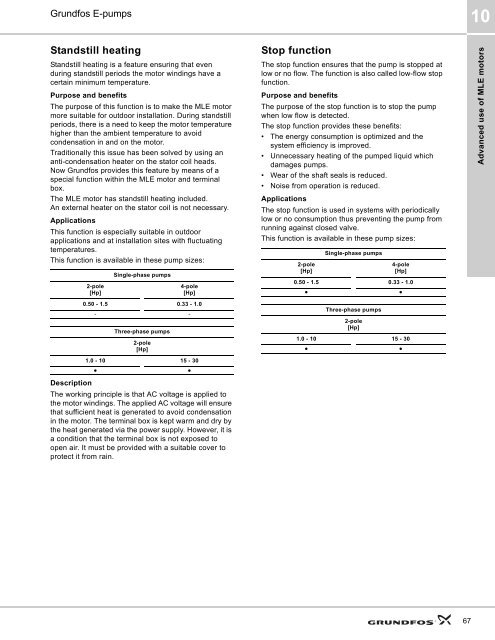

This function is available in these pump sizes:<br />

2-pole<br />

[Hp]<br />

Single-phase <strong>pumps</strong><br />

4-pole<br />

[Hp]<br />

0.50 - 1.5 0.33 - 1.0<br />

- -<br />

Three-phase <strong>pumps</strong><br />

2-pole<br />

[Hp]<br />

1.0 - 10 15 - 30<br />

●<br />

●<br />

Description<br />

The working principle is that AC voltage is applied to<br />

the motor windings. The applied AC voltage will ensure<br />

that sufficient heat is generated to avoid condensation<br />

in the motor. The terminal box is kept warm and dry by<br />

the heat generated via the power supply. However, it is<br />

a condition that the terminal box is not exposed to<br />

open air. It must be provided with a suitable cover to<br />

protect it from rain.<br />

Stop function<br />

The stop function ensures that the pump is stopped at<br />

low or no flow. The function is also called low-flow stop<br />

function.<br />

Purpose and benefits<br />

The purpose of the stop function is to stop the pump<br />

when low flow is detected.<br />

The stop function provides these benefits:<br />

• The energy consumption is optimized and the<br />

system efficiency is improved.<br />

• Unnecessary heating of the pumped liquid which<br />

damages <strong>pumps</strong>.<br />

• Wear of the shaft seals is reduced.<br />

• Noise from operation is reduced.<br />

Applications<br />

The stop function is used in systems with periodically<br />

low or no consumption thus preventing the pump from<br />

running against closed valve.<br />

This function is available in these pump sizes:<br />

2-pole<br />

[Hp]<br />

Single-phase <strong>pumps</strong><br />

4-pole<br />

[Hp]<br />

0.50 - 1.5 0.33 - 1.0<br />

●<br />

●<br />

Three-phase <strong>pumps</strong><br />

2-pole<br />

[Hp]<br />

1.0 - 10 15 - 30<br />

●<br />

●<br />

Advanced use of MLE motors<br />

67