You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Grundfos</strong> E-<strong>pumps</strong><br />

6<br />

Connecting sensor and equipment on<br />

other low-voltage inputs<br />

All connections to control inputs (terminals 1-9, 9-10,<br />

and 9-11) should be made with screened cables.<br />

To obtain an efficient EMC protection, the screen must<br />

be connected to ground/frame in both ends and be<br />

unbroken between the two connection points.<br />

It is important that the screen is connected to<br />

ground/frame as direct as possible, i.e. by means of a<br />

metal cable bracket to encircle the screen completely.<br />

See fig. 57.<br />

To ensure a good connection between the cable<br />

bracket and ground/frame, any painting and surface<br />

treatment on the metal surfaces must be removed.<br />

• If the E-pump is connected to an electronic unit,<br />

control panel, etc. with a cable clamp identical to the<br />

one on the E-pump, the screen must be connected<br />

to this cable clamp. See fig. 58.<br />

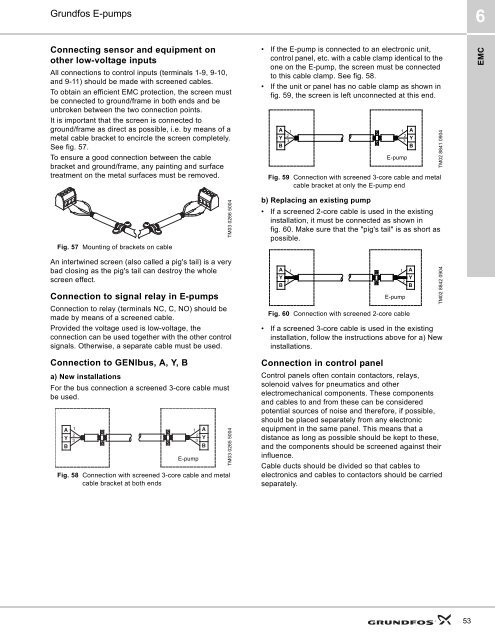

• If the unit or panel has no cable clamp as shown in<br />

fig. 59, the screen is left unconnected at this end.<br />

A<br />

Y<br />

B<br />

1<br />

2<br />

3<br />

E-pump<br />

1 A<br />

2<br />

Y<br />

3<br />

B<br />

Fig. 59 Connection with screened 3-core cable and metal<br />

cable bracket at only the E-pump end<br />

TM02 8841 0904<br />

EMC<br />

Fig. 57 Mounting of brackets on cable<br />

TM03 0266 5004<br />

b) Replacing an existing pump<br />

• If a screened 2-core cable is used in the existing<br />

installation, it must be connected as shown in<br />

fig. 60. Make sure that the "pig's tail" is as short as<br />

possible.<br />

An intertwined screen (also called a pig's tail) is a very<br />

bad closing as the pig's tail can destroy the whole<br />

screen effect.<br />

Connection to signal relay in E-<strong>pumps</strong><br />

Connection to relay (terminals NC, C, NO) should be<br />

made by means of a screened cable.<br />

Provided the voltage used is low-voltage, the<br />

connection can be used together with the other control<br />

signals. Otherwise, a separate cable must be used.<br />

Connection to GENIbus, A, Y, B<br />

a) New installations<br />

For the bus connection a screened 3-core cable must<br />

be used.<br />

A 1<br />

2<br />

Y 3<br />

B<br />

Fig. 58 Connection with screened 3-core cable and metal<br />

cable bracket at both ends<br />

1<br />

2<br />

3<br />

E-pump<br />

A<br />

Y<br />

B<br />

TM03 0265 5004<br />

A<br />

Y<br />

B<br />

1<br />

2<br />

E-pump<br />

1 A<br />

Y<br />

2<br />

B<br />

Fig. 60 Connection with screened 2-core cable<br />

• If a screened 3-core cable is used in the existing<br />

installation, follow the instructions above for a) New<br />

installations.<br />

Connection in control panel<br />

Control panels often contain contactors, relays,<br />

solenoid valves for pneumatics and other<br />

electromechanical components. These components<br />

and cables to and from these can be considered<br />

potential sources of noise and therefore, if possible,<br />

should be placed separately from any electronic<br />

equipment in the same panel. This means that a<br />

distance as long as possible should be kept to these,<br />

and the components should be screened against their<br />

influence.<br />

Cable ducts should be divided so that cables to<br />

electronics and cables to contactors should be carried<br />

separately.<br />

TM02 8842 0904<br />

53