Promoting Resource Efficiency in Small & Medium size ... - UNEP

Promoting Resource Efficiency in Small & Medium size ... - UNEP

Promoting Resource Efficiency in Small & Medium size ... - UNEP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In Figure 21 the <strong>in</strong>crease <strong>in</strong> variation that correlates to the decrease of<br />

production <strong>in</strong>dicates a deficit of process control. From the extrapolation<br />

of the <strong>in</strong>terpolation l<strong>in</strong>e towards high production, the optimum<br />

consumption can be derived. Plott<strong>in</strong>g a similar diagram with total daily<br />

water consumption and extrapolation of daily water consumption towards<br />

zero production would show fixed consumption, e.g. for daily clean<strong>in</strong>g.<br />

3.5 Act<br />

In the ‘Act’ phase the follow<strong>in</strong>g elements are important:<br />

• Preparation of an action plan<br />

• Cont<strong>in</strong>ued implementation of <strong>Resource</strong> <strong>Efficiency</strong> options<br />

(maybe <strong>in</strong> another thematic area)<br />

• Monitor<strong>in</strong>g and review<strong>in</strong>g of performance<br />

• Reward<strong>in</strong>g good performance; do not forget to reward the ones<br />

beh<strong>in</strong>d the success!<br />

Prepare an action plan to track implementation of <strong>Resource</strong> <strong>Efficiency</strong><br />

goals and prepare regular reports to management on the progress to<br />

justify time and resources used on the programme.<br />

3.6 Overlaps <strong>in</strong> the thematic areas<br />

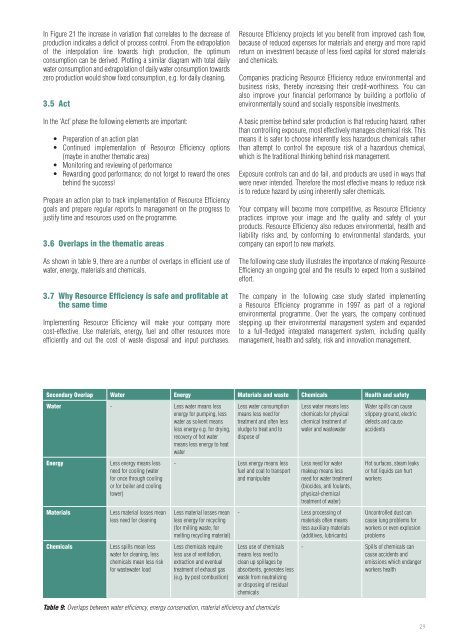

As shown <strong>in</strong> table 9, there are a number of overlaps <strong>in</strong> efficient use of<br />

water, energy, materials and chemicals.<br />

3.7 Why <strong>Resource</strong> <strong>Efficiency</strong> is safe and profitable at<br />

the same time<br />

Implement<strong>in</strong>g <strong>Resource</strong> <strong>Efficiency</strong> will make your company more<br />

cost-effective. Use materials, energy, fuel and other resources more<br />

efficiently and cut the cost of waste disposal and <strong>in</strong>put purchases.<br />

<strong>Resource</strong> <strong>Efficiency</strong> projects let you benefit from improved cash flow,<br />

because of reduced expenses for materials and energy and more rapid<br />

return on <strong>in</strong>vestment because of less fixed capital for stored materials<br />

and chemicals.<br />

Companies practic<strong>in</strong>g <strong>Resource</strong> <strong>Efficiency</strong> reduce environmental and<br />

bus<strong>in</strong>ess risks, thereby <strong>in</strong>creas<strong>in</strong>g their credit-worth<strong>in</strong>ess. You can<br />

also improve your f<strong>in</strong>ancial performance by build<strong>in</strong>g a portfolio of<br />

environmentally sound and socially responsible <strong>in</strong>vestments.<br />

A basic premise beh<strong>in</strong>d safer production is that reduc<strong>in</strong>g hazard, rather<br />

than controll<strong>in</strong>g exposure, most effectively manages chemical risk. This<br />

means it is safer to choose <strong>in</strong>herently less hazardous chemicals rather<br />

than attempt to control the exposure risk of a hazardous chemical,<br />

which is the traditional th<strong>in</strong>k<strong>in</strong>g beh<strong>in</strong>d risk management.<br />

Exposure controls can and do fail, and products are used <strong>in</strong> ways that<br />

were never <strong>in</strong>tended. Therefore the most effective means to reduce risk<br />

is to reduce hazard by us<strong>in</strong>g <strong>in</strong>herently safer chemicals.<br />

Your company will become more competitive, as <strong>Resource</strong> <strong>Efficiency</strong><br />

practices improve your image and the quality and safety of your<br />

products. <strong>Resource</strong> <strong>Efficiency</strong> also reduces environmental, health and<br />

liability risks and, by conform<strong>in</strong>g to environmental standards, your<br />

company can export to new markets.<br />

The follow<strong>in</strong>g case study illustrates the importance of mak<strong>in</strong>g <strong>Resource</strong><br />

<strong>Efficiency</strong> an ongo<strong>in</strong>g goal and the results to expect from a susta<strong>in</strong>ed<br />

effort.<br />

The company <strong>in</strong> the follow<strong>in</strong>g case study started implement<strong>in</strong>g<br />

a <strong>Resource</strong> <strong>Efficiency</strong> programme <strong>in</strong> 1997 as part of a regional<br />

environmental programme. Over the years, the company cont<strong>in</strong>ued<br />

stepp<strong>in</strong>g up their environmental management system and expanded<br />

to a full-fledged <strong>in</strong>tegrated management system, <strong>in</strong>clud<strong>in</strong>g quality<br />

management, health and safety, risk and <strong>in</strong>novation management.<br />

Secondary Overlap Water Energy Materials and waste Chemicals Health and safety<br />

Water - Less water means less<br />

energy for pump<strong>in</strong>g, less<br />

water as solvent means<br />

less energy e.g. for dry<strong>in</strong>g,<br />

recovery of hot water<br />

means less energy to heat<br />

water<br />

Less water consumption<br />

means less need for<br />

treatment and often less<br />

sludge to treat and to<br />

dispose of<br />

Less water means less<br />

chemicals for physical<br />

chemical treatment of<br />

water and wastewater<br />

Water spills can cause<br />

slippery ground, electric<br />

defects and cause<br />

accidents<br />

Energy<br />

Materials<br />

Chemicals<br />

Less energy means less<br />

need for cool<strong>in</strong>g (water<br />

for once through cool<strong>in</strong>g<br />

or for boiler and cool<strong>in</strong>g<br />

tower)<br />

Less material losses mean<br />

less need for clean<strong>in</strong>g<br />

Less spills mean less<br />

water for clean<strong>in</strong>g, less<br />

chemicals mean less risk<br />

for wastewater load<br />

- Less energy means less<br />

fuel and coal to transport<br />

and manipulate<br />

Less material losses mean<br />

less energy for recycl<strong>in</strong>g<br />

(for mill<strong>in</strong>g waste, for<br />

melt<strong>in</strong>g recycl<strong>in</strong>g material)<br />

Less chemicals require<br />

less use of ventilation,<br />

extraction and eventual<br />

treatment of exhaust gas<br />

(e.g. by post combustion)<br />

Less need for water<br />

makeup means less<br />

need for water treatment<br />

(biocides, anti foulants,<br />

physical-chemical<br />

treatment of water)<br />

- Less process<strong>in</strong>g of<br />

materials often means<br />

less auxiliary materials<br />

(additives, lubricants)<br />

Less use of chemicals<br />

means less need to<br />

clean up spillages by<br />

absorbents, generates less<br />

waste from neutraliz<strong>in</strong>g<br />

or dispos<strong>in</strong>g of residual<br />

chemicals<br />

Hot surfaces, steam leaks<br />

or hot liquids can hurt<br />

workers<br />

Uncontrolled dust can<br />

cause lung problems for<br />

workers or even explosion<br />

problems<br />

- Spills of chemicals can<br />

cause accidents and<br />

emissions which endanger<br />

workers health<br />

Table 9: Overlaps between water efficiency, energy conservation, material efficiency and chemicals<br />

29