Promoting Resource Efficiency in Small & Medium size ... - UNEP

Promoting Resource Efficiency in Small & Medium size ... - UNEP

Promoting Resource Efficiency in Small & Medium size ... - UNEP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1,2<br />

1<br />

0,8<br />

0,6<br />

Specific water consumption [m 3 /m 2 ]<br />

Ecoprofit<br />

Environmental<br />

management<br />

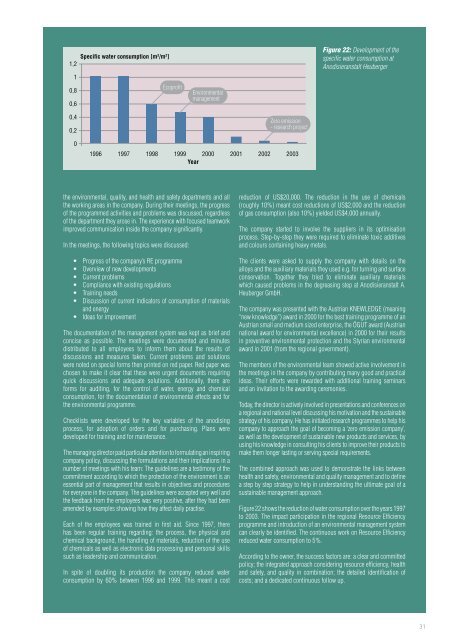

Figure 22: Development of the<br />

specific water consumption at<br />

Anodisieranstalt Heuberger<br />

0,4<br />

0,2<br />

0<br />

1996 1997 1998 1999<br />

Year<br />

Zero emission<br />

- research project<br />

2000 2001 2002 2003<br />

the environmental, quality, and health and safety departments and all<br />

the work<strong>in</strong>g areas <strong>in</strong> the company. Dur<strong>in</strong>g their meet<strong>in</strong>gs, the progress<br />

of the programmed activities and problems was discussed, regardless<br />

of the department they arose <strong>in</strong>. The experience with focused teamwork<br />

improved communication <strong>in</strong>side the company significantly.<br />

In the meet<strong>in</strong>gs, the follow<strong>in</strong>g topics were discussed:<br />

• Progress of the company’s RE programme<br />

• Overview of new developments<br />

• Current problems<br />

• Compliance with exist<strong>in</strong>g regulations<br />

• Tra<strong>in</strong><strong>in</strong>g needs<br />

• Discussion of current <strong>in</strong>dicators of consumption of materials<br />

and energy<br />

• Ideas for improvement<br />

The documentation of the management system was kept as brief and<br />

concise as possible. The meet<strong>in</strong>gs were documented and m<strong>in</strong>utes<br />

distributed to all employees to <strong>in</strong>form them about the results of<br />

discussions and measures taken. Current problems and solutions<br />

were noted on special forms then pr<strong>in</strong>ted on red paper. Red paper was<br />

chosen to make it clear that these were urgent documents requir<strong>in</strong>g<br />

quick discussions and adequate solutions. Additionally, there are<br />

forms for audit<strong>in</strong>g, for the control of water, energy and chemical<br />

consumption, for the documentation of environmental effects and for<br />

the environmental programme.<br />

Checklists were developed for the key variables of the anodis<strong>in</strong>g<br />

process, for adoption of orders and for purchas<strong>in</strong>g. Plans were<br />

developed for tra<strong>in</strong><strong>in</strong>g and for ma<strong>in</strong>tenance.<br />

The manag<strong>in</strong>g director paid particular attention to formulat<strong>in</strong>g an <strong>in</strong>spir<strong>in</strong>g<br />

company policy, discuss<strong>in</strong>g the formulations and their implications <strong>in</strong> a<br />

number of meet<strong>in</strong>gs with his team: The guidel<strong>in</strong>es are a testimony of the<br />

commitment accord<strong>in</strong>g to which the protection of the environment is an<br />

essential part of management that results <strong>in</strong> objectives and procedures<br />

for everyone <strong>in</strong> the company. The guidel<strong>in</strong>es were accepted very well and<br />

the feedback from the employees was very positive, after they had been<br />

amended by examples show<strong>in</strong>g how they affect daily practise.<br />

Each of the employees was tra<strong>in</strong>ed <strong>in</strong> first aid. S<strong>in</strong>ce 1997, there<br />

has been regular tra<strong>in</strong><strong>in</strong>g regard<strong>in</strong>g: the process, the physical and<br />

chemical background, the handl<strong>in</strong>g of materials, reduction of the use<br />

of chemicals as well as electronic data process<strong>in</strong>g and personal skills<br />

such as leadership and communication.<br />

In spite of doubl<strong>in</strong>g its production the company reduced water<br />

consumption by 60% between 1996 and 1999. This meant a cost<br />

reduction of US$20,000. The reduction <strong>in</strong> the use of chemicals<br />

(roughly 10%) meant cost reductions of US$2,000 and the reduction<br />

of gas consumption (also 10%) yielded US$4,000 annually.<br />

The company started to <strong>in</strong>volve the suppliers <strong>in</strong> its optimisation<br />

process. Step-by-step they were required to elim<strong>in</strong>ate toxic additives<br />

and colours conta<strong>in</strong><strong>in</strong>g heavy metals.<br />

The clients were asked to supply the company with details on the<br />

alloys and the auxiliary materials they used e.g. for turn<strong>in</strong>g and surface<br />

conservation. Together they tried to elim<strong>in</strong>ate auxiliary materials<br />

which caused problems <strong>in</strong> the degreas<strong>in</strong>g step at Anodisieranstalt A.<br />

Heuberger GmbH.<br />

The company was presented with the Austrian KNEWLEDGE (mean<strong>in</strong>g<br />

“new knowledge”) award <strong>in</strong> 2000 for the best tra<strong>in</strong><strong>in</strong>g programme of an<br />

Austrian small and medium <strong>size</strong>d enterprise, the ÖGUT award (Austrian<br />

national award for environmental excellence) <strong>in</strong> 2000 for their results<br />

<strong>in</strong> preventive environmental protection and the Styrian environmental<br />

award <strong>in</strong> 2001 (from the regional government).<br />

The members of the environmental team showed active <strong>in</strong>volvement <strong>in</strong><br />

the meet<strong>in</strong>gs <strong>in</strong> the company by contribut<strong>in</strong>g many good and practical<br />

ideas. Their efforts were rewarded with additional tra<strong>in</strong><strong>in</strong>g sem<strong>in</strong>ars<br />

and an <strong>in</strong>vitation to the award<strong>in</strong>g ceremonies.<br />

Today, the director is actively <strong>in</strong>volved <strong>in</strong> presentations and conferences on<br />

a regional and national level discuss<strong>in</strong>g his motivation and the susta<strong>in</strong>able<br />

strategy of his company. He has <strong>in</strong>itiated research programmes to help his<br />

company to approach the goal of becom<strong>in</strong>g a ‘zero emission company’,<br />

as well as the development of susta<strong>in</strong>able new products and services, by<br />

us<strong>in</strong>g his knowledge <strong>in</strong> consult<strong>in</strong>g his clients to improve their products to<br />

make them longer last<strong>in</strong>g or serv<strong>in</strong>g special requirements.<br />

The comb<strong>in</strong>ed approach was used to demonstrate the l<strong>in</strong>ks between<br />

health and safety, environmental and quality management and to def<strong>in</strong>e<br />

a step by step strategy to help <strong>in</strong> understand<strong>in</strong>g the ultimate goal of a<br />

susta<strong>in</strong>able management approach.<br />

Figure 22 shows the reduction of water consumption over the years 1997<br />

to 2003. The impact participation <strong>in</strong> the regional <strong>Resource</strong> <strong>Efficiency</strong><br />

programme and <strong>in</strong>troduction of an environmental management system<br />

can clearly be identified. The cont<strong>in</strong>uous work on <strong>Resource</strong> <strong>Efficiency</strong><br />

reduced water consumption to 5%.<br />

Accord<strong>in</strong>g to the owner, the success factors are: a clear and committed<br />

policy; the <strong>in</strong>tegrated approach consider<strong>in</strong>g resource efficiency, health<br />

and safety, and quality <strong>in</strong> comb<strong>in</strong>ation; the detailed identification of<br />

costs; and a dedicated cont<strong>in</strong>uous follow up.<br />

31