Using Polymer Modified Asphalt Emulsions in Surface Treatments A ...

Using Polymer Modified Asphalt Emulsions in Surface Treatments A ...

Using Polymer Modified Asphalt Emulsions in Surface Treatments A ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

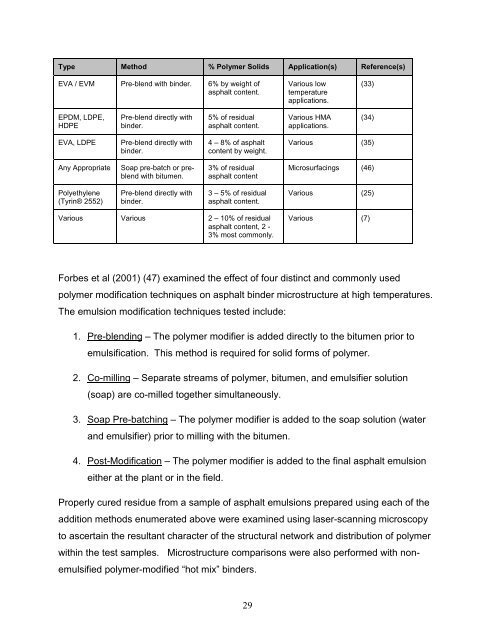

Type Method % <strong>Polymer</strong> Solids Application(s) Reference(s)<br />

EVA / EVM Pre-blend with b<strong>in</strong>der. 6% by weight of<br />

asphalt content.<br />

Various low<br />

temperature<br />

applications.<br />

(33)<br />

EPDM, LDPE,<br />

HDPE<br />

Pre-blend directly with<br />

b<strong>in</strong>der.<br />

5% of residual<br />

asphalt content.<br />

Various HMA<br />

applications.<br />

(34)<br />

EVA, LDPE<br />

Pre-blend directly with<br />

b<strong>in</strong>der.<br />

4 – 8% of asphalt<br />

content by weight.<br />

Various (35)<br />

Any Appropriate<br />

Soap pre-batch or preblend<br />

with bitumen.<br />

3% of residual<br />

asphalt content<br />

Microsurfac<strong>in</strong>gs (46)<br />

Polyethylene<br />

(Tyr<strong>in</strong>® 2552)<br />

Pre-blend directly with<br />

b<strong>in</strong>der.<br />

3 – 5% of residual<br />

asphalt content.<br />

Various (25)<br />

Various Various 2 – 10% of residual<br />

asphalt content, 2 -<br />

3% most commonly.<br />

Various (7)<br />

Forbes et al (2001) (47) exam<strong>in</strong>ed the effect of four dist<strong>in</strong>ct and commonly used<br />

polymer modification techniques on asphalt b<strong>in</strong>der microstructure at high temperatures.<br />

The emulsion modification techniques tested <strong>in</strong>clude:<br />

1. Pre-blend<strong>in</strong>g – The polymer modifier is added directly to the bitumen prior to<br />

emulsification. This method is required for solid forms of polymer.<br />

2. Co-mill<strong>in</strong>g – Separate streams of polymer, bitumen, and emulsifier solution<br />

(soap) are co-milled together simultaneously.<br />

3. Soap Pre-batch<strong>in</strong>g – The polymer modifier is added to the soap solution (water<br />

and emulsifier) prior to mill<strong>in</strong>g with the bitumen.<br />

4. Post-Modification – The polymer modifier is added to the f<strong>in</strong>al asphalt emulsion<br />

either at the plant or <strong>in</strong> the field.<br />

Properly cured residue from a sample of asphalt emulsions prepared us<strong>in</strong>g each of the<br />

addition methods enumerated above were exam<strong>in</strong>ed us<strong>in</strong>g laser-scann<strong>in</strong>g microscopy<br />

to ascerta<strong>in</strong> the resultant character of the structural network and distribution of polymer<br />

with<strong>in</strong> the test samples. Microstructure comparisons were also performed with nonemulsified<br />

polymer-modified “hot mix” b<strong>in</strong>ders.<br />

29