Using Polymer Modified Asphalt Emulsions in Surface Treatments A ...

Using Polymer Modified Asphalt Emulsions in Surface Treatments A ...

Using Polymer Modified Asphalt Emulsions in Surface Treatments A ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

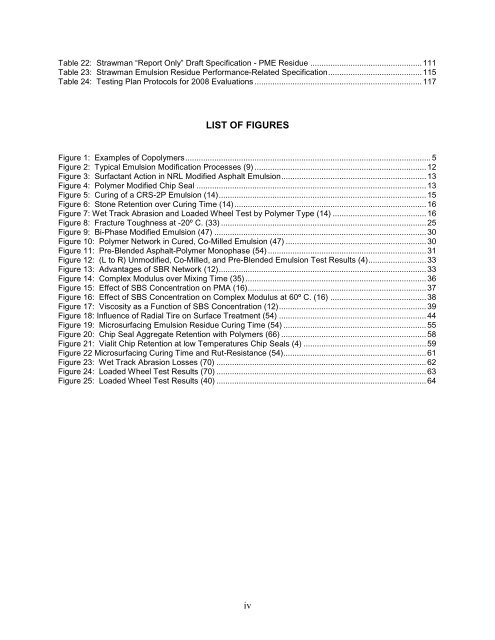

Table 22: Strawman “Report Only” Draft Specification - PME Residue .................................................. 111<br />

Table 23: Strawman Emulsion Residue Performance-Related Specification .......................................... 115<br />

Table 24: Test<strong>in</strong>g Plan Protocols for 2008 Evaluations ........................................................................... 117<br />

LIST OF FIGURES<br />

Figure 1: Examples of Copolymers .............................................................................................................. 5<br />

Figure 2: Typical Emulsion Modification Processes (9) ............................................................................. 12<br />

Figure 3: Surfactant Action <strong>in</strong> NRL <strong>Modified</strong> <strong>Asphalt</strong> Emulsion ................................................................. 13<br />

Figure 4: <strong>Polymer</strong> <strong>Modified</strong> Chip Seal ....................................................................................................... 13<br />

Figure 5: Cur<strong>in</strong>g of a CRS-2P Emulsion (14) ............................................................................................. 15<br />

Figure 6: Stone Retention over Cur<strong>in</strong>g Time (14) ...................................................................................... 16<br />

Figure 7: Wet Track Abrasion and Loaded Wheel Test by <strong>Polymer</strong> Type (14) .......................................... 16<br />

Figure 8: Fracture Toughness at -20º C. (33) ............................................................................................ 25<br />

Figure 9: Bi-Phase <strong>Modified</strong> Emulsion (47) ............................................................................................... 30<br />

Figure 10: <strong>Polymer</strong> Network <strong>in</strong> Cured, Co-Milled Emulsion (47) ............................................................... 30<br />

Figure 11: Pre-Blended <strong>Asphalt</strong>-<strong>Polymer</strong> Monophase (54) ....................................................................... 31<br />

Figure 12: (L to R) Unmodified, Co-Milled, and Pre-Blended Emulsion Test Results (4) .......................... 33<br />

Figure 13: Advantages of SBR Network (12) ............................................................................................. 33<br />

Figure 14: Complex Modulus over Mix<strong>in</strong>g Time (35) ................................................................................. 36<br />

Figure 15: Effect of SBS Concentration on PMA (16) ................................................................................ 37<br />

Figure 16: Effect of SBS Concentration on Complex Modulus at 60º C. (16) ........................................... 38<br />

Figure 17: Viscosity as a Function of SBS Concentration (12) .................................................................. 39<br />

Figure 18: Influence of Radial Tire on <strong>Surface</strong> Treatment (54) .................................................................. 44<br />

Figure 19: Microsurfac<strong>in</strong>g Emulsion Residue Cur<strong>in</strong>g Time (54) ................................................................ 55<br />

Figure 20: Chip Seal Aggregate Retention with <strong>Polymer</strong>s (66) ................................................................. 58<br />

Figure 21: Vialit Chip Retention at low Temperatures Chip Seals (4) ....................................................... 59<br />

Figure 22 Microsurfac<strong>in</strong>g Cur<strong>in</strong>g Time and Rut-Resistance (54) ................................................................ 61<br />

Figure 23: Wet Track Abrasion Losses (70) .............................................................................................. 62<br />

Figure 24: Loaded Wheel Test Results (70) .............................................................................................. 63<br />

Figure 25: Loaded Wheel Test Results (40) .............................................................................................. 64<br />

iv