Catalog LV 70 2011 - Low & Medium Voltage - Siemens

Catalog LV 70 2011 - Low & Medium Voltage - Siemens

Catalog LV 70 2011 - Low & Medium Voltage - Siemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

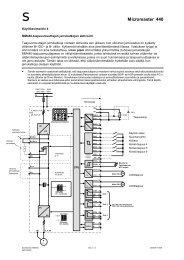

BD2 System — 160 ... 1250 A<br />

© <strong>Siemens</strong> AG <strong>2011</strong><br />

Configuration information<br />

Comparison of busbar trunking and cable installation systems<br />

Feature Busbar trunking installation Cable installation<br />

TTA assembly Yes No<br />

Mechanical safety High <strong>Low</strong><br />

Fire load <strong>Low</strong> High<br />

Temperature characteristic<br />

System structure<br />

Protective devices for loads<br />

Ambient temperature<br />

according to IEC/EN 60439-1 and -2<br />

max. +40 °C and +35 °C on a 24 hour average<br />

Clearly structured thanks to a linear system configuration<br />

with serially arranged load outgoings via tap-off<br />

units<br />

In the tap-off unit:<br />

Means direct and immediate on-the-spot identification<br />

of assignment to load<br />

Cable loads are related to +30 °C in accordance with<br />

DIN 57298 Part 4/VDE 0298 Part 4/2.88.<br />

Very large accumulation of cables at feed point due to<br />

point-to-point supply of loads from central power distribution<br />

unit<br />

Centrally in the distribution board:<br />

Makes the assignment to the load not directly verifiable.<br />

It is necessary to rely on correct inscription of the<br />

cables and loads.<br />

Space requirement <strong>Low</strong> High, because correspondingly large distribution<br />

boards are required. Routing criteria (cable accumulation,<br />

type of routing, current carrying capacity, etc.)<br />

must be complied with.<br />

Retrofitting capability if load feeders<br />

are changed<br />

Planning and configuration<br />

Dimensioning (current, voltage drop,<br />

protective earth conditions)<br />

Great flexibility due to tap-off points in the trunking<br />

units and a great number of different tap-off units<br />

Simple and fast with EDP-aided planning tools being<br />

used<br />

Not complex<br />

Only possible at great expense; laying additional<br />

cables from the central distribution board to the load.<br />

Highly intensive engineering (distribution and cable<br />

layouts, cable plans, etc.)<br />

Very complex<br />

Troubleshooting <strong>Low</strong> High<br />

Fire barrier Type-tested, ex-works Dependent on the work standard applied on the<br />

building site<br />

Functional endurance<br />

Tested functional endurance according to<br />

DIN 4102-12<br />

Dependent on the work standard applied on the<br />

building site<br />

Electromagnetic interference <strong>Low</strong>, due to sheet-steel enclosure and conductor configuration<br />

Relatively high with a standard cable<br />

Mounting<br />

Very little fitting materials and tools required,<br />

short mounting times<br />

Complex mounting materials and a comprehensive<br />

range of tools required, long mounting times<br />

Weight Up to 1/3 of the comparable cable weight Up to 3-times the busbar trunking system weight<br />

Halogen and PVC free Trunking units are always halogen and PVC free Standard cables are not always halogen and PVC free<br />

5<br />

5/92 <strong>Siemens</strong> <strong>LV</strong> <strong>70</strong> · 04/<strong>2011</strong>