- Page 2:

INTRODUCTION Read this manual caref

- Page 6 and 7:

MACHINE NUMBERS The manufacturing N

- Page 8 and 9:

CONTENTS MACHINE NUMBERS SAFETY Rec

- Page 10 and 11:

CONTENTS Maintenance Guide.........

- Page 12 and 13:

SAFETY RECOGNIZE SAFETY INFORMATION

- Page 14 and 15:

SAFETY PREPARE FOR EMERGENCIES •

- Page 16 and 17:

SAFETY USE HANDHOLDS AND STEPS •

- Page 18 and 19:

SAFETY OPERATE ONLY FROM OPERATOR'S

- Page 20 and 21:

SAFETY INVESTIGATE JOB SITE BEFOREH

- Page 22 and 23:

SAFETY DRIVE MACHINE SAFELY • Bef

- Page 24 and 25:

AVOID INJURY FROM ROLLAWAY ACCIDENT

- Page 26 and 27:

KEEP PERSON CLEAR FROM WORKING AREA

- Page 28 and 29:

SAFETY DIG WITH CAUTION • Acciden

- Page 30 and 31:

SAFETY PROTECT AGAINST FLYING DEBRI

- Page 32 and 33:

SAFETY PRACTICE SAFE MAINTENANCE To

- Page 34 and 35:

SAFETY PREVENT PARTS FROM FLYING

- Page 36 and 37:

SAFETY AVOID HIGH-PRESSURE FLUIDS

- Page 38 and 39:

SAFETY EVACUATING IN CASE OF FIRE

- Page 40 and 41:

SAFETY BEWARE OF ASBESTOS DUST •

- Page 42 and 43:

SAFETY SIGNS/Europe/Asia/Middle and

- Page 44 and 45:

SAFETY SIGNS/Europe/Asia/Middle and

- Page 46 and 47:

SAFETY SIGNS/Europe/Asia/Middle and

- Page 48 and 49:

SAFETY SIGNS/Europe/Asia/Middle and

- Page 50 and 51:

OPERATOR'S COMPONENTS STATION NAME

- Page 52 and 53:

OPERATOR'S STATION MULTI FUNCTION M

- Page 54 and 55:

OPERATOR'S STATION • Display of M

- Page 56 and 57:

OPERATOR'S STATION Menu Screen (23)

- Page 58 and 59:

OPERATOR'S STATION Menu Key Shifts

- Page 60 and 61:

Displaying Basic Screen by Password

- Page 62 and 63:

OPERATOR'S STATION 3. If inputting

- Page 64 and 65:

OPERATOR'S STATION ALARM OCCURRENCE

- Page 66 and 67:

OPERATOR'S STATION CONTENTS OF ALAR

- Page 68 and 69:

OPERATOR'S STATION CLOCK SETTING Pr

- Page 70 and 71:

OPERATOR'S STATION Selecting an Att

- Page 72 and 73:

OPERATOR'S STATION Pulverizer 1 Max

- Page 74 and 75:

DISPLAYING OPERATING CONDITIONS OPE

- Page 76 and 77:

OPERATOR'S STATION 4. Push key 6 ,

- Page 78 and 79:

4. Push key 6 , and return to the b

- Page 80 and 81:

OPERATOR'S STATION Password Change

- Page 82 and 83:

OPERATOR'S STATION 7. The message

- Page 84 and 85:

OPERATOR'S STATION Auto-Control: OF

- Page 86 and 87:

OPERATOR'S STATION Change Interval

- Page 88 and 89:

OPERATOR'S STATION Screen Display w

- Page 90 and 91:

OPERATOR'S STATION Mail (Optional)

- Page 92 and 93:

OPERATOR'S STATION LANGUAGE SETTING

- Page 94 and 95:

OPERATOR'S STATION SWITCH PANEL 1-

- Page 96 and 97:

OPERATOR'S STATION POWER MODE SWITC

- Page 98 and 99:

OPERATOR'S STATION WIPER/WASHER SWI

- Page 100 and 101:

OPERATOR'S STATION SWITCH PANEL (Op

- Page 102 and 103:

OPERATOR'S STATION KEY SWITCH 1- OF

- Page 104 and 105:

OPERATOR'S STATION CAB LIGHT Turn t

- Page 106 and 107:

OPERATOR'S STATION FUSE BOX 10- CON

- Page 108 and 109:

OPERATOR'S STATION Control Panel De

- Page 110 and 111:

OPERATOR'S STATION • Circulation

- Page 112 and 113:

OPERATOR'S STATION DEFROSTER OPERAT

- Page 114 and 115:

OPERATOR'S STATION CAB HEATER (Opti

- Page 116 and 117:

OPERATOR'S STATION DEFROSTER OPERAT

- Page 118 and 119:

OPERATOR'S STATION Station Presetti

- Page 120 and 121:

OPERATOR'S STATION CLOSING UPPER FR

- Page 122 and 123:

OPERATOR'S STATION OPENING/CLOSING

- Page 124 and 125:

OPERATOR'S STATION ADJUSTING THE SE

- Page 126 and 127:

ADJUSTING THE AIR-SUSPENSION SEAT (

- Page 128 and 129:

OPERATOR'S STATION ADJUSTING CONSOL

- Page 130 and 131:

BREAK-IN OBSERVE ENGINE OPERATION C

- Page 132 and 133:

OPERATING THE ENGINE INSPECT MACHIN

- Page 134 and 135:

OPERATING THE ENGINE STARTING THE E

- Page 136 and 137:

OPERATING THE ENGINE STARTING IN CO

- Page 138 and 139:

CHECK INSTRUMENTS AFTER STARTING OP

- Page 140 and 141:

OPERATING THE ENGINE Disconnecting

- Page 142 and 143:

DRIVING THE MACHINE DRIVE THE MACHI

- Page 144 and 145:

STEERING THE MACHINE USING LEVERS D

- Page 146 and 147:

DRIVING THE MACHINE OPERATING ON SO

- Page 148 and 149:

DRIVING THE MACHINE OPERATING IN WA

- Page 150 and 151:

OPERATING THE MACHINE CONTROL LEVER

- Page 152 and 153:

OPERATING THE MACHINE ATTACHMENT PE

- Page 154 and 155:

OPERATING THE MACHINE Warming-up Op

- Page 156 and 157:

OPERATING THE MACHINE AUTO-IDLE 1 W

- Page 158 and 159:

OPERATING THE MACHINE WORK MODE SEL

- Page 160 and 161:

OPERATING THE MACHINE POWER MODE On

- Page 162 and 163:

OPERATING THE MACHINE FACE SHOVEL O

- Page 164 and 165:

OPERATING THE MACHINE HYDRAULIC BRE

- Page 166 and 167:

ZX180-3, 200-3, 270-3, 330-3 Class

- Page 168 and 169:

OPERATING THE MACHINE Pressure Meas

- Page 170 and 171:

OPERATING THE MACHINE • Do not op

- Page 172 and 173:

OPERATING THE MACHINE BREAKER MAINT

- Page 174 and 175:

OPERATING THE MACHINE • When oper

- Page 176 and 177:

OPERATING THE MACHINE • Breaker o

- Page 178 and 179:

Crusher (ZX120-3 Class) OPERATING T

- Page 180 and 181: OPERATING THE MACHINE PRECAUTION FO

- Page 182 and 183: EMERGENCY BOOM LOWERING PROCEDURE (

- Page 184 and 185: OBJECT HANDLING --- IF EQUIPPED OPE

- Page 186 and 187: TRANSPORTING TRANSPORTING BY ROAD W

- Page 188 and 189: 4. Stop the engine. Remove the key

- Page 190 and 191: TRANSPORTING MACHINE LIFTING PROCED

- Page 192 and 193: CORRECT MAINTENANCE AND INSPECTION

- Page 194 and 195: MAINTENANCE LAYOUT Arm Cylinder Arm

- Page 196 and 197: MAINTENANCE Maintenance Guide Table

- Page 198 and 199: MAINTENANCE HOOD AND ACCESS COVERS

- Page 200 and 201: MAINTENANCE PERIODIC REPLACEMENT OF

- Page 202 and 203: MAINTENANCE C. TRANSMISSION (See Pa

- Page 204 and 205: H. ELECTRICAL SYSTEM (See Page 7-62

- Page 206 and 207: MAINTENANCE Brand Names of Recommen

- Page 208 and 209: MAINTENANCE • Boom and Arm Joint

- Page 210 and 211: MAINTENANCE 3 Swing Internal Gear -

- Page 212 and 213: MAINTENANCE 2 Change Engine Oil ---

- Page 214 and 215: MAINTENANCE C. TRANSMISSION 1 Pump

- Page 216 and 217: MAINTENANCE 3 Travel Reduction Gear

- Page 218 and 219: MAINTENANCE D. HYDRAULIC SYSTEM INS

- Page 220 and 221: MAINTENANCE BREAKER MAINTENANCE Cha

- Page 222 and 223: MAINTENANCE 2 Change Hydraulic Oil

- Page 224 and 225: MAINTENANCE Air Bleeding Procedures

- Page 226 and 227: MAINTENANCE 5 Replace Pilot Oil Fil

- Page 228 and 229: MAINTENANCE 7 Check Hoses and Lines

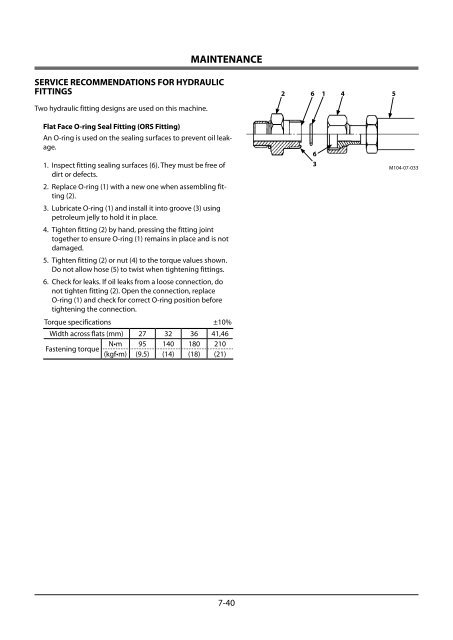

- Page 232 and 233: MAINTENANCE Metal Face Seal Fitting

- Page 234 and 235: MAINTENANCE 8. To avoid condensatio

- Page 236 and 237: MAINTENANCE 2 Drain Fuel Filter ---

- Page 238 and 239: MAINTENANCE Air Bleeding Procedures

- Page 240 and 241: MAINTENANCE 3 Replace Fuel Main Fil

- Page 242 and 243: MAINTENANCE 5 Clean Fuel Solenoid P

- Page 244 and 245: MAINTENANCE F. AIR CLEANER 1 Clean

- Page 246 and 247: MAINTENANCE G. COOLING SYSTEM Coola

- Page 248 and 249: MAINTENANCE 1 Check Coolant Level -

- Page 250 and 251: MAINTENANCE 2 Check and Adjust Fan

- Page 252 and 253: MAINTENANCE 4 Clean Radiator, Oil C

- Page 254 and 255: MAINTENANCE If acid is swallowed: 1

- Page 256 and 257: MAINTENANCE Check electrolyte speci

- Page 258 and 259: MAINTENANCE • Fusible Link (Main

- Page 260 and 261: 3. Clean shank (6) surface. 4. Inst

- Page 262 and 263: MAINTENANCE c. Removing the tooth p

- Page 264 and 265: MAINTENANCE 3 Convert Bucket Connec

- Page 266 and 267: MAINTENANCE 5 Remove Travel Levers

- Page 268 and 269: MAINTENANCE 8 Check Track Sag --- e

- Page 270 and 271: MAINTENANCE 9 Clean and Replace Air

- Page 272 and 273: MAINTENANCE 10 Check Air Conditione

- Page 274 and 275: MAINTENANCE 12 Retighten Cylinder H

- Page 276 and 277: MAINTENANCE 17 Check Tightening Tor

- Page 278 and 279: MAINTENANCE 17 Check Tightening Tor

- Page 280 and 281:

MAINTENANCE 17 Check Tightening Tor

- Page 282 and 283:

1. Engine cushion rubber mounting b

- Page 284 and 285:

MAINTENANCE 6. Pump transmission mo

- Page 286 and 287:

MAINTENANCE 12. Battery mounting nu

- Page 288 and 289:

MAINTENANCE 17. Travel device mount

- Page 290 and 291:

HYDRAULIC CIRCUIT HYDRAULIC CIRCUIT

- Page 292 and 293:

ELECTRICAL DIAGRAM 8-

- Page 294 and 295:

MAINTENANCE UNDER SPECIAL ENVIRONME

- Page 296 and 297:

STORAGE STORING THE MACHINE 1. Insp

- Page 298 and 299:

TROUBLESHOOTING IMPOSSIBLE TO START

- Page 300 and 301:

TROUBLESHOOTING ENGINE Problem Caus

- Page 302 and 303:

TROUBLESHOOTING ENGINE Problem Caus

- Page 304 and 305:

TROUBLESHOOTING ELECTRICAL SYSTEM P

- Page 306 and 307:

TROUBLESHOOTING CONTROL LEVERS Prob

- Page 308 and 309:

TROUBLESHOOTING HYDRAULIC SYSTEM Pr

- Page 310 and 311:

SPECIFICATIONS SPECIFICATIONS ZX110

- Page 312 and 313:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 314 and 315:

SPECIFICATIONS BUCKET TYPES AND APP

- Page 316 and 317:

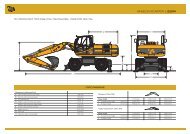

SPECIFICATIONS WORKING RANGES ZX130

- Page 318 and 319:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 320 and 321:

SPECIFICATIONS SPECIFICATIONS ZX160

- Page 322 and 323:

SPECIFICATIONS ZX160LC-3 (Machine w

- Page 324 and 325:

SPECIFICATIONS BUCKET TYPES AND APP

- Page 326 and 327:

SPECIFICATIONS WORKING RANGES ZX180

- Page 328 and 329:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 330 and 331:

SPECIFICATIONS SPECIFICATIONS ZX210

- Page 332 and 333:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 334 and 335:

SPECIFICATIONS SPECIFICATIONS ZX210

- Page 336 and 337:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 338 and 339:

SPECIFICATIONS SPECIFICATIONS ZX250

- Page 340 and 341:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 342 and 343:

SPECIFICATIONS SPECIFICATIONS ZX280

- Page 344 and 345:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 346 and 347:

SPECIFICATIONS SPECIFICATIONS ZX350

- Page 348 and 349:

SPECIFICATIONS SHOE TYPES AND APPLI

- Page 350 and 351:

SPECIFICATIONS SOUND LEVEL RESULTS

- Page 352 and 353:

USING PAD CRAWLER SHOE ZX120-3, 200

- Page 354 and 355:

OPTIONAL ATTACHMENTS AND DEVICES TR

- Page 356 and 357:

OPTIONAL ATTACHMENTS AND DEVICES Lo

- Page 358 and 359:

OPTIONAL ATTACHMENTS AND DEVICES BL

- Page 360 and 361:

OPTIONAL ATTACHMENTS AND DEVICES BL

- Page 362 and 363:

OPTIONAL ATTACHMENTS AND DEVICES WO

- Page 364 and 365:

OPTIONAL ATTACHMENTS AND DEVICES SP

- Page 366 and 367:

SHOE TYPES AND APPLICATIONS ZX130-3

- Page 368 and 369:

OFFSET DIRECTION AND WORKING RANGE

- Page 370 and 371:

OPTIONAL ATTACHMENTS AND DEVICES MA

- Page 372 and 373:

OPTIONAL ATTACHMENTS AND DEVICES WO

- Page 374 and 375:

OPTIONAL ATTACHMENTS AND DEVICES 2-

- Page 376 and 377:

OPTIONAL ATTACHMENTS AND DEVICES

- Page 378 and 379:

OPTIONAL ATTACHMENTS AND DEVICES SP

- Page 380 and 381:

SHOE TYPES AND APPLICATIONS ZX130-3

- Page 382 and 383:

OPTIONAL ATTACHMENTS AND DEVICES SP

- Page 384 and 385:

SHOE TYPES AND APPLICATIONS OPTIONA

- Page 386 and 387:

OPTIONAL ATTACHMENTS AND DEVICES WO

- Page 388 and 389:

OPTIONAL ATTACHMENTS AND DEVICES SP

- Page 390 and 391:

SHOE TYPES AND APPLICATIONS OPTIONA

- Page 392 and 393:

OPTIONAL ATTACHMENTS AND DEVICES WO

- Page 394 and 395:

OPTIONAL ATTACHMENTS AND DEVICES SP

- Page 396 and 397:

SHOE TYPES AND APPLICATIONS OPTIONA

- Page 398 and 399:

OPTIONAL ATTACHMENTS AND DEVICES WA

- Page 400 and 401:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 402 and 403:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 404 and 405:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 406 and 407:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 408 and 409:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 410 and 411:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 412 and 413:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 414 and 415:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 416 and 417:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 418 and 419:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 420 and 421:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 422 and 423:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 424 and 425:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 426 and 427:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 428 and 429:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 430 and 431:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 432 and 433:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 434 and 435:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 436 and 437:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 438 and 439:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 440 and 441:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 442 and 443:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 444 and 445:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 446 and 447:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 448 and 449:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 450 and 451:

LIFTING CAPACITIES OPTIONAL ATTACHM

- Page 452 and 453:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 454 and 455:

OPTIONAL ATTACHMENTS AND DEVICES LI

- Page 456 and 457:

INDEX 2 2-piece Boom...............

- Page 458 and 459:

INDEX Never Undercut a High Bank...

- Page 460 and 461:

Working Ranges ZX280LC-3, 280LCN-3