design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

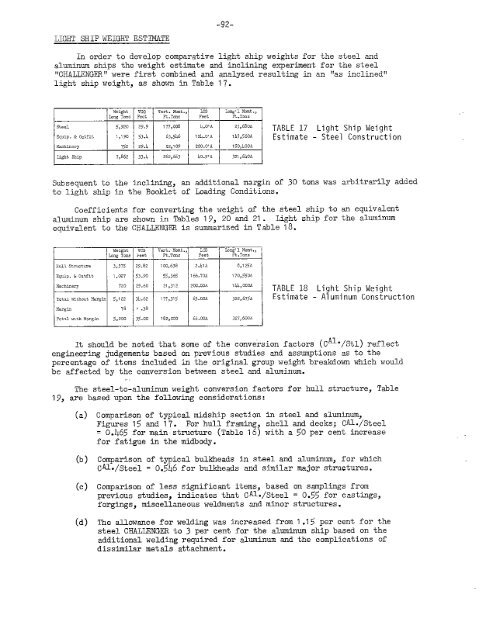

LIGHT SHIP WEIGHT ESTIMATE-92-In order to develop comparative light ship weights <strong>for</strong> the steel and<strong>aluminum</strong> ships the weight estimate and inclining experiment <strong>for</strong> the steel!TCHAL~NG~l?were first combined and analyzed resulting h an “as inclined”light ship weight, as shown in Table 17.Weight VCG Vert.Nomt., ICG Lak:rl Momt.,~onzhn~ FOC* Ft.~on~ Feet W.Tonssteel 5,9202P.9 177,008 l(.OIA 23,660.! TABLE 17 Light <strong>Ship</strong> WeightEquip.& Outfit 1,I9o 53.4 63,5116 12h.O,A 1.h7,560A Estimate - Steel ConstructionMathinc?y 752 29.11 22,109 200.0tA 150,1JoohLight<strong>Ship</strong> 7,862 33.4 262,E&3 h0.9rA 321,640ASubsequent to the inclining, an additional margin of 30 tons wasto light ship in the Booklet of Loading Conditions.arbitrarily addedCoefficients <strong>for</strong> converting the weight of the steel ship to<strong>aluminum</strong> ship are shown in Tables 19, 20 and 21- Light ship <strong>for</strong>equivalent to the CHALLENG~ is summarized in ‘Table18.an equivalentthe <strong>aluminum</strong>Wel~htVCG Vd. MomL., 1,m IOng]lMom+.,LongT0n8 >e.t II.Tons Feet Fk.TonsHuIJ<strong>Structure</strong> 3,375 27.82 100,638 2,41A 8,12FJlEquip,L Outfit 1,027 53.90 55,365 I 66.7oA 170,55’o11Machinery 7?0 29.60 21,312 2LJ3.00A 144, 000A 1 TABLE 18 Light <strong>Ship</strong> WeightTotalWiLh.ntMargin 5,122 3h.62 177,315 63.00A 322,675A Estimate - Aluminum ConstructionMargin 78 , .38Total w,thMI+II 5,200 35.00 182,000 63. 00A 327, 600AIt should be noted that some of the conversion factors (C‘l”/Stl) reflecten~ineerti~ .Iudgementsbased on previous studies and assumptions as to thepercentage-o~ i;ems included h ~he original group weight breakdown which wouldbe affected by the converz%on between steel and <strong>aluminum</strong>.“.The steel-to-<strong>aluminum</strong>weight conversion factors <strong>for</strong> <strong>hull</strong> structure, Table19, are based upon the following <strong>considerations</strong>:(a)(b)(c)(d)Comparison of typical midship section in steel and <strong>aluminum</strong>,Figures 15 and 17. For <strong>hull</strong> framing, shell and decks; CA~./Steel= 0.465 <strong>for</strong> mainstmcture (Table 16) with a SO per cent increase<strong>for</strong> fatigue in the midbody.Comparison of typical bulkheads in steel and <strong>aluminum</strong>, <strong>for</strong> whichC~*/Steel = 0S46 <strong>for</strong> bulkheads and similar major <strong>structures</strong>.Comparison of less significant items, based on samplings fromprevious studies, indicates that C~*/Steel = OSS <strong>for</strong> castfigs,<strong>for</strong>gings, miscellaneous weldments amd minor <strong>structures</strong>.The allowmce <strong>for</strong> welding was increased from 1.1S per cent <strong>for</strong> thesteel CHALLENGER to 3 per cent <strong>for</strong> the <strong>aluminum</strong> ship based on theadditional welding required <strong>for</strong> <strong>aluminum</strong> and the complications ofdissimilar metals attachment.