design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

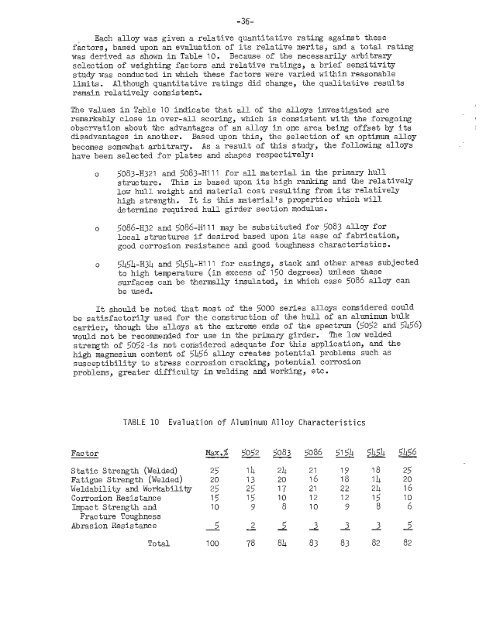

.36-Each alloy was given a relative quantitative rating against thesefactors, based upon an evaluation of its relative merits, and a total ratingwas derived as shmwn in Table 10. Because of the necessarily arbitraryselection of weighting factors and relative ratings, a brief sensitivitystudy was conducted in which these factors were varied within reasonablelimits. Although quantitative ratings did change, the qualitative resultsremain relatively consistent.The values in Table 10 indicate that all of the alloys investigated areremarkably close in over-all scoring, which is consistent with the <strong>for</strong>egoingobservation about the advantages of an alloy in one area being offset by itsdisadvantages in another. Based upon this, the selection of an optimum alloybecomes somewhat arbitrary. As a result of this study, the following alloyshave been selected YOY plates and shapes respectively:o S083-H321 ands083-Hill <strong>for</strong> all material in the prima~ <strong>hull</strong>structure. This is based upon its high ranking and the relativelylow <strong>hull</strong> weight and material cost resulting from its’relativelyhigh stirength. It is this materially properties which willdetermine required <strong>hull</strong> girder section modulus.o S086-H32 and!71086-Hillmaybe substituted <strong>for</strong> S083 a~~oy<strong>for</strong>local <strong>structures</strong> if desired based upon its ease of fabrication,good corrosion resistance and good toughness characteristics.o s4sb-H34 andSLS4-Hill <strong>for</strong>casingsj stack and otherareas subjectedto high temperature (in excess of 1S0 degrees) unless thesesurfaces can be thermally insulated, in which case S086 alloy canbe used.It should be noted that most of the JOOO series alloys considered couldbe satisfactorily used <strong>for</strong> the construction of the <strong>hull</strong> of an <strong>aluminum</strong> bulkcari-ier,though the a~oys at the extreme emds Of the sPectm (~0~2 and ~~~~6)would not be recommended <strong>for</strong> use in the primary girder. The low weldedstrength of sOS2-is not considered adequate <strong>for</strong> this application and thehigh magnesium con”~entof 5456 d-10Y creates potential p~o~~ernssuch aSsusceptibility to stress corrosion cracking, potential corrosionproblems, greater difficulty in welding and working, etc.TABLE 10 EYa” udtion of Aluminum Alloy CharacteristicsFactorm.% 5052 5083 5086 5154 5454 ~—— — — —Static Strength (Welded) 25 14 24 21 19 18 25Fatigue Strength (Welded) 20 20 16 18 14 20Weldability and Workability 25 ~i 17 21 22 24 16Corrosion Resistance 15 15 10 12 12 15 10Impact,Strength and 10 !7 8 10 9 8 6Fracture ToughnessAbrasion Resistance >~~J22 2Total 100 78 8L 83 83 82 82