design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

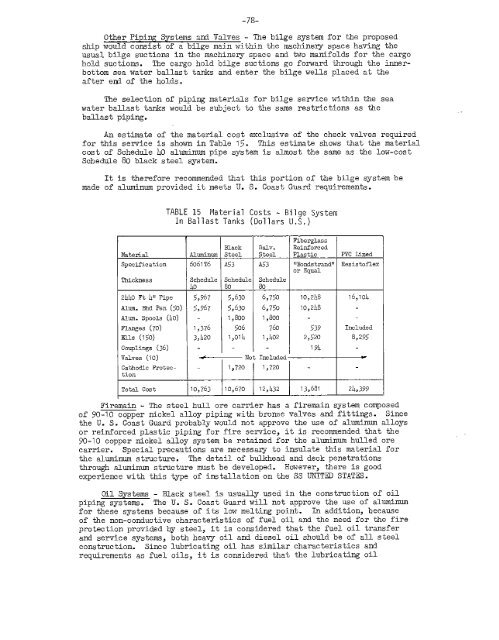

-78-Other Piping Systems and Valves - The bilge system <strong>for</strong> the proposedship would consist of a bilge main within the machinery space having theusual bilge suctions in the machinery space and two manifolds <strong>for</strong> the cargohold suctions. The cargo hold bilge suctions go <strong>for</strong>ward through the innerbotiomsea water ballast tanks and enter the bilge wells placed at theafter eni of the holds.The selection of piping materials <strong>for</strong> bilge service within the seawater ballast tanks would be subject to the same restrictions as tieballast piping.An estimate of the material cost exclusive of the check valves required<strong>for</strong> this service is shown in Table 1S. This estimate shows that the rnat.erialcost of Schedule ~~0<strong>aluminum</strong> pipe system is almost the same as the low-costSchedule 8(Iblack steel system.It is the~e<strong>for</strong>e recommended that this portion of bhe bilge system bemade of <strong>aluminum</strong> provided it meets U. S. Coast Guard requirements.Thickness2440 Ft 11~]PipeAlum. Bhd Pen (S0)Alum. spoolsTABLE 15 Material Costs - Bilge SystemIn Ballast Tanks (Dollars U.S.)(Llo)Flanges (70)Ku (150)couplings(36)ScheduleScheduh40 805,967 5,6305,967 5,6301,8001,376 5063,i.120 1,014Galv.SteelAS3Schedul~806,7s06,7~o1,8007601,402Valves (10) ~ Not IncludeiCathodicProtec- I,720 I,720tiionITotalcost ]10,763 110,670/12,432FiberglassRein<strong>for</strong>cedPlastic PVC Lined%ondstrandttResistofIexor Equal+10,24810,2485392,52019413,68116,104Includ~d—8,29524,399Firemain - The steel <strong>hull</strong> ore carrier has a firemain system composedof 90-10 copper nickel alloy piping with bronze valves and fittings. Sincethe U. S. Coast (hard probably would not approve the use of <strong>aluminum</strong> alloysor rein<strong>for</strong>ced plastic piping <strong>for</strong> fire service, it is recommended that the90-10 copper nickel alloy system be retained <strong>for</strong> the <strong>aluminum</strong> <strong>hull</strong>ed orecarrier. Special precautions are necessary to insulate this material <strong>for</strong>the <strong>aluminum</strong> structure. The detail of bulkhead and deck penetrationsthrough <strong>aluminum</strong> structure must be developed. However, there is goodexperiencewith this type of installation on the SS UNITED STATES.Oil Systems - Black steel is usually used in the construction of oilpiping systems. The U. S. Coast Guard will not approve the use of <strong>aluminum</strong><strong>for</strong> these systems because of ik low melting point. In addition, becauseof the non-conductivecharacteristicsof fuel oil and the need <strong>for</strong> the fireprotection provided by steel, it is considered that the fuel oil transferand service systems, both heavy oil and diesel oil should be of all steelconstruction. Since lubricating oil has similar characteristicsandrequirements as fuel oils, it is considered that the lubricating oil