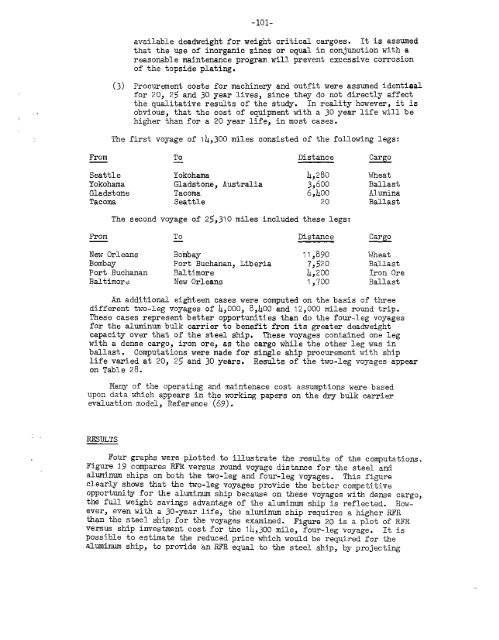

GaseNumber. . . -.,- .TABLE 27 Comparison of Steel and Hlwm!.m Bulk Larrlers<strong>Ship</strong> Life(Years)No. of <strong>Ship</strong>sPurchasedS%ruckure~faterialRoumd VoyageDistance( Cti2tanCQP ClasAnnual GargoCarried-L.T.1)2)3)4)5)6)7)8)9)1o)11)12)13)14)15)16)17)18)19)20)21)22)23)24)25)26)27)28)29)30)31)32)33)34)35)%)202020202020252525.252525’30303030303020202020202025’2525252525;:3030303015’1015’105’10;105105107.5105101510510SteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelSteelAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminumAluminum14,30014,30014,3002~,3;O25’,3Io2~,31014,30014,30014,30025,3102s,3102S,31o14,30014,30014,30025’,3102s,31025’,3I0!4,30014,30014,3002s,31o2s531o2g,31014,30014,300IL,3002S,3102S,31o2s,310lh,30014,300lh,30Q2s,3702s,31o2s,31o514,1015!14,1015’14,101309,646309,6116309,61J6.5’12,816572,816.5’12,816308,872308,872308,872512,8165’12,816512,816308,872308,872308,872533,759533;759533,759325;688325,688325,688533,759533,7595’33,759325,688325,688325,688533,759533,759533,759325,688325,688325,688+ <strong>Ship</strong>Trice + Ownerls Invest. Costs - Salvage Value

Fromavailable deadweight <strong>for</strong> weight critical cargoes. It is assumedthat the use of inorganic zincs or equal in conjunction with areasonable maintenance program will prevent excessive corrosionof the topside plating.(3) Procwement costs <strong>for</strong> machinery and outfit were assumed identiaal<strong>for</strong> 20, 2S and 30 year lives, since they do not directly affectthe qualitative results of the study. In reality however, i% isobvious, that the cost of equipment with a 30 year life will behigher than <strong>for</strong> a 20 year life, in most cases.The first voyage of I,!I,300miles consisted of the following legs:%0—DistanceSeattle Yokohama 4,280 WheatYokohama Gladstone, Australia 3,600 BallastGladstone Tacoma 6,400 AluminaTacoma Seattle 20 BallastThe second voyage of 2S,310 miles included these legs:From To Distance— -New Orleans Bohbay 11,890 WheatBombay Port Buchanan, Liberia 7,~20 BallastPort Buchanan Baltimore 4,2oo Iron OreBaltimore New Orleans 1,700 BallastAn additional eighteen cases were computed on the basis of threedifferent two-leg voyages of 4,000, 8,4oo and 12,000 miles round trip.These cases represent better opportunities than do the four-leg voyages<strong>for</strong> the <strong>aluminum</strong> bulk carrier to benefit from its g~eater deadweightcapacity over that of the steel ship. These voyages contained one legwith a dense cargo, iron ore, as the cargo while the other leg was inballast. Computations were made <strong>for</strong> single ship procurement with shiplife varied at 20, 25 and 30 years. Results of the two-leg voyages appearon Table 28.Many of the operating and maintenancecost assumptions were basedupon data which appears in the working papers on the dry bulk carrierevaluation model, Reference (69).RESULTS-1o1-Four graphs were plotted to illustrate the results of the computations.Figure 3.9compares RFR versus round voyage distance <strong>for</strong> the steel and<strong>aluminum</strong> ships on both the two-leg and four-leg voyages. This figureclearly shows that the two-leg voyages provide the better competitiveopportuni~ <strong>for</strong> the <strong>aluminum</strong> ship because on these voyages with dense cargo,the full weight savings advantage of the <strong>aluminum</strong> ship is reflected. However,even with a 30-year life, the <strong>aluminum</strong> ship requires a higher RFRthan the steel ship <strong>for</strong> the voyages examined. Fi~re 20 is a plot of RFRversus ship investment cost <strong>for</strong> the 14,300 mile, four-leg voyage. It ispossible to estimate the reduced price which would be required <strong>for</strong> the<strong>aluminum</strong> ship, to provide an.RFR equal to the steel ship, by projecting

- Page 5:

CONTENTSI.. II.III.Iv.v.VI ●VII.I

- Page 9 and 10:

LIST OF FIGURES(Cent’d)FIGURE NO.

- Page 11 and 12:

I. INTRODUCTIONThis report summariz

- Page 13:

art in fabricating and maintaining

- Page 16 and 17:

MONTEROSSO GRANA /17VALGRANA / CARA

- Page 18 and 19:

-8-Numerous references have been re

- Page 20 and 21:

.10.TABLE 2. Mechanical Properties

- Page 22 and 23:

TABLE 2 Mechanical Properties of Al

- Page 24 and 25:

TABLE 3 Mechanical Property Limits

- Page 26 and 27:

-16-l?igures5, 6, 7 ati 8 present f

- Page 28 and 29:

-18-ti-’”’-”-””””-L

- Page 30 and 31:

-20-60 .r---.— ..,.— -——,L-

- Page 32 and 33:

.22-each stress level, rate of load

- Page 34 and 35:

-24-!Z456-H321 = 0.485083-H321 = 0.

- Page 36 and 37:

-26-(c)Members with partial or cont

- Page 38 and 39:

-28-AllOyS 5083 and 54.56(~ content

- Page 40 and 41:

-30-The previous paragraphs have de

- Page 42 and 43:

-32-The problem of cargo hold abras

- Page 44 and 45:

-34-The question of residual stress

- Page 46 and 47:

.36-Each alloy was given a relative

- Page 48 and 49:

-38-GENERAL OBSERVATIONSFYior to a

- Page 50 and 51:

-40-The question of comparative imp

- Page 52 and 53:

-42-(d)(e)Poor quality welds due to

- Page 54 and 55:

-44-The ABS criteria noted above we

- Page 56 and 57:

-46-DNV would consider fatigue in e

- Page 58 and 59:

-48-is less, for the exposed side s

- Page 60 and 61: Equation (2):-50-Hu1l SMa~um = Hull

- Page 62 and 63: -52-Another aspect of vibrations wh

- Page 64 and 65: -54-000000000Bottom Shell PlateSide

- Page 66 and 67: -56-at the deck and keel. This stre

- Page 68 and 69: -58-AT is the change inUT= Thermal

- Page 70 and 71: -60-SUl@!ARYAll parties contacted f

- Page 72 and 73: -62-(c)(d)(e)(f)T~e exterior side o

- Page 74 and 75: TABLE 12 Aluminum Bulk Carrier - Su

- Page 76 and 77: .66-INSUT.ATION AND SHEATHINGShell8

- Page 78 and 79: -68-(b)(c)(d)(e)(f)(g)(h)(i)(j)At l

- Page 80 and 81: -70-IIF.INSTALLATION OF SYSTEMS AND

- Page 82 and 83: Rudder Assembly -carrier should be

- Page 84 and 85: -74-(b)MechanicalTensile Strength 6

- Page 86 and 87: -76-(e)The steel piping must be of

- Page 88 and 89: -78-Other Piping Systems and Valves

- Page 90 and 91: -80-struetion for the aluminum hull

- Page 92 and 93: -82-Large heavy type machine~ must

- Page 94 and 95: suffers attack in an alkaline envir

- Page 96 and 97: -86-REPAIRSObtaining proper repairs

- Page 98 and 99: -88-The design of the midship s~cti

- Page 100 and 101: -90-assuming the increase is applic

- Page 102 and 103: LIGHT SHIP WEIGHT ESTIMATE-92-In or

- Page 104 and 105: -94-TABLE 20 Aluminum Bulk Carrier

- Page 106 and 107: TABLE 22 Trim and StabilityFull Loa

- Page 108 and 109: -98-TABLE 24 Price of Steel Bulk Ca

- Page 112 and 113: -1o2-TABLE 28CarriersComparison of

- Page 114 and 115: 12 ---n..T.[T7%l,=LEGS IU ORF=ErY

- Page 116 and 117: -106-such as iron ore, on two of th

- Page 118 and 119: -108-7)is,zg~ gg~5e mzz~E’4E!~K2j

- Page 120 and 121: -11o-(a)(b)(c)(d)Inerting system fo

- Page 122 and 123: -112-fatigue, particularly in the p

- Page 124 and 125: -114-2k* Installation of Systems an

- Page 126 and 127: -116-LIST OF REFERENCES(7)Fatigue P

- Page 128 and 129: -11.8-LLST OF REFERENCES(Cent’d)(

- Page 130 and 131: -120-ADDITIONAL SOURCES OF INFORMAT

- Page 132 and 133: -122-redistribution of the still wa

- Page 134 and 135: -124-APPENDIX BEXCERPTS FROMRULES A

- Page 136 and 137: -126-92.07-10(d)(~) Interior stairs

- Page 138 and 139: -128-~gE1+0102030- .. ..—405060

- Page 140 and 141: ectintyclassification4KEYWORDSROLEL

- Page 142: SHIP STRUCTURE COMMITTEE PUBLICATIO