design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

design considerations for aluminum hull structures - Ship Structure ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

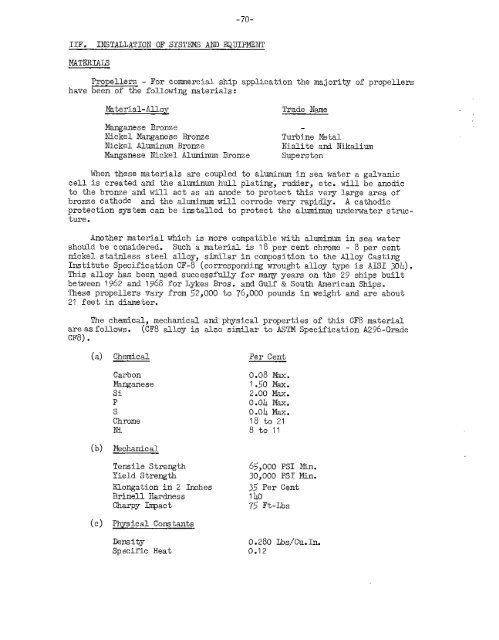

-70-IIF.INSTALLATION OF SYSTEMS AND FQUIPMENTMATERIALShavePropellers - For cormnercialship application the majority of propellersbeen of the following materials:Material-AlloyManganese BronzeNickel Manganese BronzeNickel Aluminum BronzeManganese Nickel Aluminum BronzeTrade NameTurbine MetalNialite awl NikaliumSuperstonWhen these materials are coupled to <strong>aluminum</strong> in sea water a galvaticcell is created and the <strong>aluminum</strong> <strong>hull</strong> platim, rudder. etc. will be anodicto the bronze and will act as an anode-to pr~~ect thi~ vexy large area ofbronze cathode and the ahmin-mnwill corrode vexy rapidly. A cathodicprotection system can be installed to protect the <strong>aluminum</strong> underwater structure.Another material which is more compatible with <strong>aluminum</strong> in sea watershould be considered. Such a material is 18 per cent chrome - 8 per centnickel stainless steel alloy, similar in composition to the Alloy CastingInstitute Specification CF-8 (corresponding wrought alloy type is AISI 304).This alloy has been used successfully <strong>for</strong> many years on the 29 ships builtbetween 1962 and 1968 <strong>for</strong> Lykes Bros. and Gulf & South American <strong>Ship</strong>s.These propellers vary from ~2,000 to 76,000 pounds in weight and are about21 feet in diameter.The chemical, mechanical and physical properties of this CF8 materialare as follows. (CF8 alloyis also similar to ASTM Specification A296-GradeCF8).(a)(b)(c)ChemicalCarbonM@aneseSiPsChromeNiMechanicalTensile StrengthYield StrengthElongation in 2 InchesBrinell HardnessCharpy ImpactPhysical ConstantsDsnsitySpecific HeatPer Cent0.08 w.1.50 Max.2.00 k.0.04 k.0.04 Max.18 to 218 to 1165,000 PSI Min.30,000 PsT Mill.~~oPer Cent75 Ft-Lbs0.280 Lbs/Cu.In.0.12