Combining submerged membrane technology with anaerobic and ...

Combining submerged membrane technology with anaerobic and ...

Combining submerged membrane technology with anaerobic and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

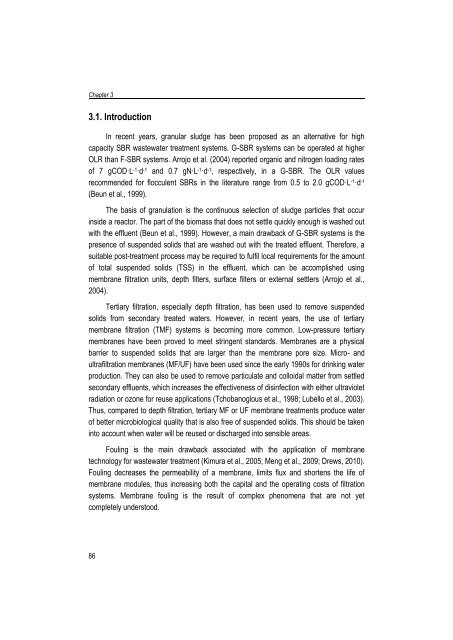

Chapter 33.1. IntroductionIn recent years, granular sludge has been proposed as an alternative for highcapacity SBR wastewater treatment systems. G-SBR systems can be operated at higherOLR than F-SBR systems. Arrojo et al. (2004) reported organic <strong>and</strong> nitrogen loading ratesof 7 gCOD·L -1·d-1 <strong>and</strong> 0.7 gN·L -1·d-1 , respectively, in a G-SBR. The OLR valuesrecommended for flocculent SBRs in the literature range from 0.5 to 2.0 gCOD·L-1·d-1(Beun et al., 1999).The basis of granulation is the continuous selection of sludge particles that occurinside a reactor. The part of the biomass that does not settle quickly enough is washed out<strong>with</strong> the effluent (Beun et al., 1999). However, a main drawback of G-SBR systems is thepresence of suspended solids that are washed out <strong>with</strong> the treated effluent. Therefore, asuitable post-treatment process may be required to fulfil local requirements for the amountof total suspended solids (TSS) in the effluent, which can be accomplished using<strong>membrane</strong> filtration units, depth filters, surface filters or external settlers (Arrojo et al.,2004).Tertiary filtration, especially depth filtration, has been used to remove suspendedsolids from secondary treated waters. However, in recent years, the use of tertiary<strong>membrane</strong> filtration (TMF) systems is becoming more common. Low-pressure tertiary<strong>membrane</strong>s have been proved to meet stringent st<strong>and</strong>ards. Membranes are a physicalbarrier to suspended solids that are larger than the <strong>membrane</strong> pore size. Micro- <strong>and</strong>ultrafiltration <strong>membrane</strong>s (MF/UF) have been used since the early 1990s for drinking waterproduction. They can also be used to remove particulate <strong>and</strong> colloidal matter from settledsecondary effluents, which increases the effectiveness of disinfection <strong>with</strong> either ultravioletradiation or ozone for reuse applications (Tchobanoglous et al., 1998; Lubello et al., 2003).Thus, compared to depth filtration, tertiary MF or UF <strong>membrane</strong> treatments produce waterof better microbiological quality that is also free of suspended solids. This should be takeninto account when water will be reused or discharged into sensible areas.Fouling is the main drawback associated <strong>with</strong> the application of <strong>membrane</strong><strong>technology</strong> for wastewater treatment (Kimura et al., 2005; Meng et al., 2009; Drews, 2010).Fouling decreases the permeability of a <strong>membrane</strong>, limits flux <strong>and</strong> shortens the life of<strong>membrane</strong> modules, thus increasing both the capital <strong>and</strong> the operating costs of filtrationsystems. Membrane fouling is the result of complex phenomena that are not yetcompletely understood.86