Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

APPENDIX C RESULTS OF RUGGEDNESS AMT TESTING<br />

Mix 5 was used for performing the AMT ruggedness tests. The target optimized proportions for<br />

M5 were 10% emulsion, 8% water, 0% liquid additive, and 0.5% type 2 cement. There were six<br />

conditions which were adjusted for evaluation. The room temperature used was either 73.4°F<br />

(23°C) or 80.6°F (27°C). The humidity condition used was either 40% or 60%. The emulsion<br />

content used was either 8% or 12%. The liquid additive used was either 0% or 0.1%. The<br />

mineral filler proportion used was either 0% or 1%.<br />

The AMT data for the trials are contained in Table C.1 and the traces fro the trials are illustrated<br />

in Figures C.1 through C.4..<br />

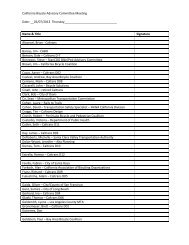

AMT Ruggedness - Mix: M5<br />

Parameter<br />

Trial #<br />

Cement, %<br />

Liquid Add, %: Al Sulfate<br />

Water, %<br />

Table C.1: AMT Ruggedness Trial Data<br />

Emulsion, %<br />

Humidity, %<br />

Aggregate, g<br />

°F °C<br />

1 10 1 0.1 10 8 80.6 27 40 300 3 30 0.3 24 10.0 1:15 2:00 3:00<br />

2 3 0 0.1 10 12 73.4 23 60 300 0 30 0.3 36 9.0 2:30 n/a 5+<br />

3 6 0 0 10 12 80.6 27 40 300 0 30 0 36 9.5 1:15 n/a 5+<br />

4 12 1 0 6 12 80.6 27 60 300 3 18 0 36 9.5 1:15 2:00 3:00<br />

5 5 0 0.1 6 8 80.6 27 60 300 0 18 0.3 24 9.0 0:15 0:30 1:00<br />

6 7 1 0 10 8 73.4 23 60 300 3 30 0 24 9.5 2:30 3:45 4:30<br />

7 9 1 0.1 6 12 73.4 23 40 300 3 18 0.3 36 11.3 1:15 2:30 3:00<br />

8 1 0 0 6 8 73.4 23 40 300 0 18 0 24 11.0 0:15 0:40 1:15<br />

Unit % % % % % %<br />

design 0.5 0 8 10 25 25 50<br />

Parameter<br />

1. Fill<br />

2. Additive<br />

3. Water<br />

4. Emulsion<br />

Temperature<br />

5. Temperature<br />

6. Humidity<br />

°F °C<br />

1 0.05 0.1 2 -2 80.6 27 40<br />

2 -0.05 0.1 2 2 73.4 23 60<br />

3 -0.05 -0.1 2 2 80.6 27 40<br />

4 0.5 -0.1 -2 2 80.6 27 60<br />

5 -0.5 0.1 -2 -2 80.6 27 60<br />

6 0.5 -0.1 2 -2 73.4 23 60<br />

7 0.5 0.1 -2 2 73.4 23 40<br />

8 -0.5 -0.1 -2 -2 73.4 23 40<br />

Unit % % % % % C %<br />

120<br />

Cement, %<br />

Water, %<br />

Liquid Add, %:______<br />

Emulsion, %<br />

Mix Index: steady state<br />

torque<br />

Mix Time: time where steady<br />

increase of torque begins<br />

Spread Time: time where<br />

torque reaches 12 N-cm<br />

Time when mix has broken