You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

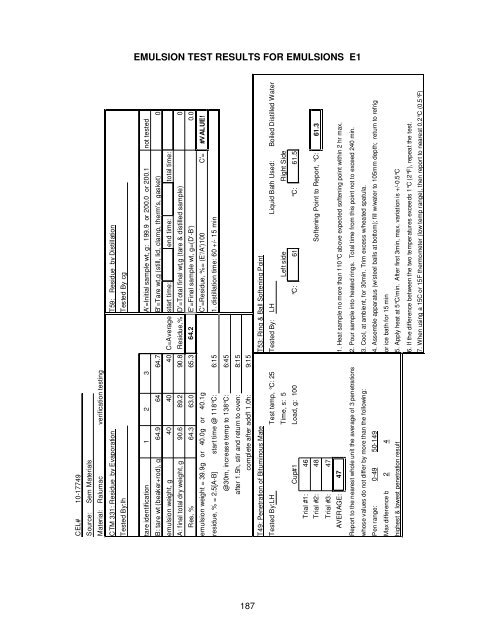

CEL# 10-17749<br />

Source: Sem Materials<br />

Material: Ralumac verification testing<br />

CTM 331: Residue by Evaporation T59: Residue by Distillation<br />

Tested By:lh Tested By:cg<br />

EMULSION TEST RESULTS FOR EMULSIONS E1<br />

tare identification 1 2 3 A'=Initial sample wt, g: 199.9 or 200.0 or 200.1 not tested<br />

B: tare wt (beaker+rod), g 64.9 64 64.7 B'=Tare wt,g (still, lid, clamp, therm's, gasket) 0<br />

emulsion weight, g 40 40 40 C=Average start time: end time: total time:<br />

A: final total dry weight, g 90.6 89.2 90.8 Residue,% D'=Total final wt,g (tare & distilled sample) 0<br />

Res, % 64.3 63.0 65.3 64.2 E'=Final sample wt, g=(D'-B') 0.0<br />

emulsion weight = 39.9g or 40.0g or 40.1g C'=Residue, %= (E'/A')100 C'= #VALUE!<br />

residue, % = 2.5[A-B] start time @ 118°C: 6:15 1. distillation time: 60 +/- 15 min<br />

@30m, increase temp to 138°C: 6:45<br />

after 1.5h, stir and return to oven: 8:15<br />

complete after add'l 1.0h: 9:15<br />

187<br />

T49: Penetration of Bituminous Materials<br />

T53: Ring & Ball Softening Point<br />

Tested By:LH Test temp, °C: 25 Tested By: LH Liquid Bath Used: Boiled Distilled Water<br />

Time, s: 5 Left side Right Side<br />

Cup#1 Load, g: 100 °C: 61 °C: 61.5<br />

Trial #1: 46<br />

Trial #2: 48 Softening Point to Report, °C: 61.3<br />

Trial #3: 47<br />

AVERAGE: 47 1. Heat sample no more than 110°C above expected softening point within 2 hr max.<br />

Report to the nearest whole unit the average of 3 penetrations 2. Pour sample into heated rings. Total time from this point not to exceed 240 min.<br />

whose values do not differ by more than the following: 3. Cool, at ambient, for 30min. Trim excess w/heated spatula.<br />

Pen range: 0-49 50-149 4. Assemble apparatus (w/steel balls at bottom); fill w/water to 105mm depth; return to refrig<br />

Max difference between 2 4 or ice bath for 15 min<br />

highest & lowest penetration result 5. Apply heat at 5°C/min. After first 3min, max. variation is +/-0.5°C<br />

6. If the difference between the two temperatures exceeds 1°C (2°F), repeat the test.<br />

7. When using a 15C or 15F thermometer (low temp range), then report to nearest 0.2°C (0.5°F)