You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

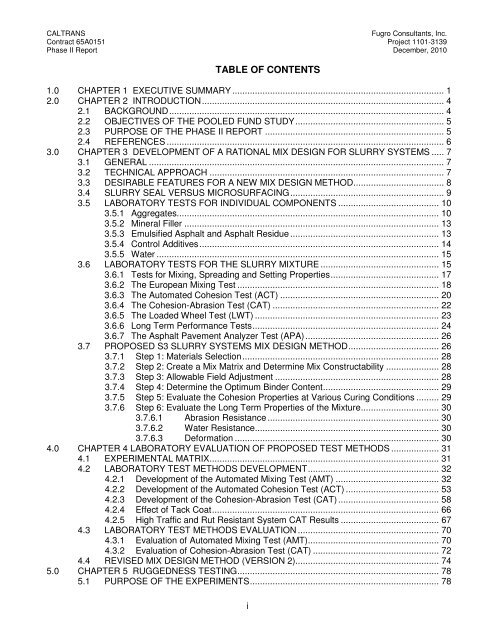

CALTRANS Fugro Consultants, Inc.<br />

Contract 65A0151 Project 1101-3139<br />

Phase <strong>II</strong> Report December, 2010<br />

TABLE OF CONTENTS<br />

1.0 CHAPTER 1 EXECUTIVE SUMMARY.................................................................................... 1<br />

2.0 CHAPTER 2 INTRODUCTION................................................................................................ 4<br />

2.1 BACKGROUND............................................................................................................. 4<br />

2.2 OBJECTIVES OF THE POOLED FUND STUDY........................................................... 5<br />

2.3 PURPOSE OF THE <strong>PHASE</strong> <strong>II</strong> <strong>REPORT</strong> ....................................................................... 5<br />

2.4 REFERENCES .............................................................................................................. 6<br />

3.0 CHAPTER 3 DEVELOPMENT OF A RATIONAL MIX DESIGN FOR SLURRY SYSTEMS ..... 7<br />

3.1 GENERAL ..................................................................................................................... 7<br />

3.2 TECHNICAL APPROACH ............................................................................................. 7<br />

3.3 DESIRABLE FEATURES FOR A NEW MIX DESIGN METHOD.................................... 8<br />

3.4 SLURRY SEAL VERSUS MICROSURFACING............................................................. 9<br />

3.5 LABORATORY TESTS FOR INDIVIDUAL COMPONENTS ........................................ 10<br />

3.5.1 Aggregates........................................................................................................ 10<br />

3.5.2 Mineral Filler ..................................................................................................... 13<br />

3.5.3 Emulsified Asphalt and Asphalt Residue ........................................................... 13<br />

3.5.4 Control Additives............................................................................................... 14<br />

3.5.5 Water ................................................................................................................ 15<br />

3.6 LABORATORY TESTS FOR THE SLURRY MIXTURE ............................................... 15<br />

3.6.1 Tests for Mixing, Spreading and Setting Properties........................................... 17<br />

3.6.2 The European Mixing Test ................................................................................ 18<br />

3.6.3 The Automated Cohesion Test (ACT) ............................................................... 20<br />

3.6.4 The Cohesion-Abrasion Test (CAT) .................................................................. 22<br />

3.6.5 The Loaded Wheel Test (LWT) ......................................................................... 23<br />

3.6.6 Long Term Performance Tests.......................................................................... 24<br />

3.6.7 The Asphalt Pavement Analyzer Test (APA)..................................................... 26<br />

3.7 PROPOSED S3 SLURRY SYSTEMS MIX DESIGN METHOD.................................... 26<br />

3.7.1 Step 1: Materials Selection.............................................................................. 28<br />

3.7.2 Step 2: Create a Mix Matrix and Determine Mix Constructability ..................... 28<br />

3.7.3 Step 3: Allowable Field Adjustment ................................................................. 28<br />

3.7.4 Step 4: Determine the Optimum Binder Content.............................................. 29<br />

3.7.5 Step 5: Evaluate the Cohesion Properties at Various Curing Conditions ......... 29<br />

3.7.6 Step 6: Evaluate the Long Term Properties of the Mixture............................... 30<br />

3.7.6.1 Abrasion Resistance .................................................................... 30<br />

3.7.6.2 Water Resistance......................................................................... 30<br />

3.7.6.3 Deformation ................................................................................. 30<br />

4.0 CHAPTER 4 LABORATORY EVALUATION OF PROPOSED TEST METHODS ................... 31<br />

4.1 EXPERIMENTAL MATRIX........................................................................................... 31<br />

4.2 LABORATORY TEST METHODS DEVELOPMENT.................................................... 32<br />

4.2.1 Development of the Automated Mixing Test (AMT) ......................................... 32<br />

4.2.2 Development of the Automated Cohesion Test (ACT) ..................................... 53<br />

4.2.3 Development of the Cohesion-Abrasion Test (CAT)........................................ 58<br />

4.2.4 Effect of Tack Coat.......................................................................................... 66<br />

4.2.5 High Traffic and Rut Resistant System CAT Results ....................................... 67<br />

4.3 LABORATORY TEST METHODS EVALUATION ........................................................ 70<br />

4.3.1 Evaluation of Automated Mixing Test (AMT).................................................... 70<br />

4.3.2 Evaluation of Cohesion-Abrasion Test (CAT) .................................................. 72<br />

4.4 REVISED MIX DESIGN METHOD (VERSION 2)......................................................... 74<br />

5.0 CHAPTER 5 RUGGEDNESS TESTING................................................................................ 78<br />

5.1 PURPOSE OF THE EXPERIMENTS........................................................................... 78<br />

i