Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

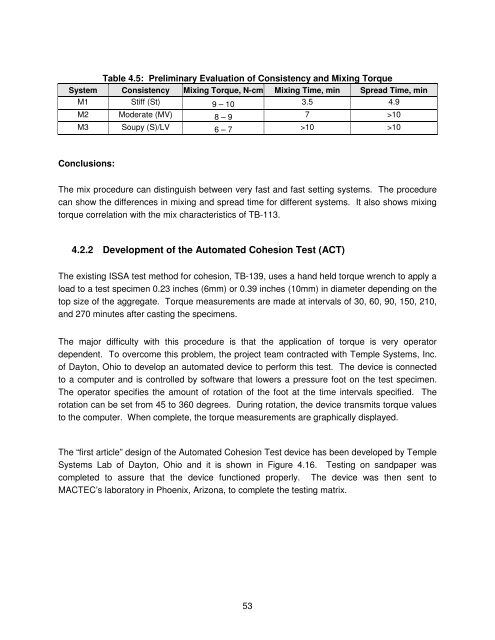

Table 4.5: Preliminary Evaluation of Consistency and Mixing Torque<br />

System Consistency Mixing Torque, N-cm Mixing Time, min Spread Time, min<br />

M1 Stiff (St) 9 – 10 3.5 4.9<br />

M2 Moderate (MV) 8 – 9 7 >10<br />

M3 Soupy (S)/LV 6 – 7 >10 >10<br />

Conclusions:<br />

The mix procedure can distinguish between very fast and fast setting systems. The procedure<br />

can show the differences in mixing and spread time for different systems. It also shows mixing<br />

torque correlation with the mix characteristics of TB-113.<br />

4.2.2 Development of the Automated Cohesion Test (ACT)<br />

The existing ISSA test method for cohesion, TB-139, uses a hand held torque wrench to apply a<br />

load to a test specimen 0.23 inches (6mm) or 0.39 inches (10mm) in diameter depending on the<br />

top size of the aggregate. Torque measurements are made at intervals of 30, 60, 90, 150, 210,<br />

and 270 minutes after casting the specimens.<br />

The major difficulty with this procedure is that the application of torque is very operator<br />

dependent. To overcome this problem, the project team contracted with Temple Systems, Inc.<br />

of Dayton, Ohio to develop an automated device to perform this test. The device is connected<br />

to a computer and is controlled by software that lowers a pressure foot on the test specimen.<br />

The operator specifies the amount of rotation of the foot at the time intervals specified. The<br />

rotation can be set from 45 to 360 degrees. During rotation, the device transmits torque values<br />

to the computer. When complete, the torque measurements are graphically displayed.<br />

The “first article” design of the Automated Cohesion Test device has been developed by Temple<br />

Systems Lab of Dayton, Ohio and it is shown in Figure 4.16. Testing on sandpaper was<br />

completed to assure that the device functioned properly. The device was then sent to<br />

MACTEC’s laboratory in Phoenix, Arizona, to complete the testing matrix.<br />

53