- Page 1 and 2:

Building a digital strategy around

- Page 3 and 4:

FOREWORD W elcome to the December e

- Page 5 and 6:

USA EDITION Click the home icon (to

- Page 7 and 8:

48 Talent retention: why traditiona

- Page 9 and 10:

116 Visions Federal Credit Union 13

- Page 11:

194 KUBRA 224 eStruxture 208 DRA Gl

- Page 15 and 16:

Automation Anywhere: Rashim Mogha i

- Page 17 and 18:

17 “Say yes to every opportunity

- Page 19 and 20:

CLICK TO WATCH: ‘RASHIM MOGHA, AU

- Page 21 and 22:

Automation Anywhere’s Enterprise

- Page 23 and 24:

2003 Year founded 1,500,000+ bots a

- Page 25 and 26:

25 to reaching out and empowering 1

- Page 27 and 28:

BRIGHTER FUTURES Looking to the fut

- Page 29 and 30:

www.businesschief.com 29

- Page 31 and 32:

www.businesschief.com 31

- Page 33 and 34:

CLICK TO WATCH: ‘IMPROVE CUSTOMER

- Page 35 and 36:

“The company is constantly evalua

- Page 37 and 38:

architecture, all the way through t

- Page 39 and 40:

www.businesschief.com HAVE YOU SEEN

- Page 41 and 42:

DATA ANALYTICS FOR GOOD - THE NEXT

- Page 43 and 44:

43 and NGOs need to know where the

- Page 45 and 46:

CLICK TO WATCH: ‘WHAT COULD 5G DO

- Page 47 and 48:

insights are used to solve problems

- Page 49 and 50:

www.businesschief.com 49

- Page 51 and 52:

51 Being ‘conscious’ is an impo

- Page 53 and 54:

CLICK TO WATCH: ‘WORKPLACE TRANSF

- Page 55 and 56:

55 in other companies, resulting in

- Page 57 and 58:

www.businesschief.com 57

- Page 59 and 60:

59 pollution and greenhouse gases,

- Page 61 and 62:

CLICK TO WATCH: ‘SUPPLY CHAIN SOF

- Page 63 and 64:

“Simple changes to packaging will

- Page 65 and 66:

NIX 65 NIX www.businesschief.com

- Page 67 and 68:

1.626mn Population of Phoenix, Ariz

- Page 69 and 70:

HOW WE GOT HERE In 2004, the US Dep

- Page 71 and 72:

of mapping out some streets in Los

- Page 73 and 74:

Wealthiest individuals in the US 73

- Page 75:

75 09 Alice Walton $53.1bn Alice Wa

- Page 78 and 79:

TOP 10 78 07 Sergey Brin $53.9bn Se

- Page 80 and 81:

Reimagine the impossible Bring toge

- Page 82 and 83:

TOP 10 82 04 Larry Ellison $68.7bn

- Page 84 and 85:

TOP 10 84 02 Bill Gates $105.5bn Se

- Page 86 and 87:

TOP 10 86 Bezos giving NASA Deputy

- Page 88 and 89:

88 IPG: building technology, teams

- Page 90 and 91:

INTERPUBLIC GROUP Chris White, Depu

- Page 92 and 93:

INTERPUBLIC GROUP 92 “Every singl

- Page 94 and 95:

INTERPUBLIC GROUP 94 Across global

- Page 96 and 97:

Interpublic Group Adds Business Val

- Page 98 and 99:

INTERPUBLIC GROUP 98 addition to ca

- Page 100 and 101:

INTERPUBLIC GROUP 100 IPG Chairman

- Page 102 and 103:

102 DECEMBER 2019

- Page 104 and 105:

TUENTI ECUADOR Gerardo Suárez Napo

- Page 106 and 107:

TUENTI ECUADOR 106 The Tuenti brand

- Page 108 and 109:

TUENTI ECUADOR simplicity of Tuenti

- Page 110 and 111:

TUENTI ECUADOR 110 “MEETING AND E

- Page 112 and 113:

TUENTI ECUADOR “LESS POWERPOINT,

- Page 114 and 115:

TUENTI ECUADOR 114 suit the needs o

- Page 116 and 117:

Visions Federal Credit Union: 116 b

- Page 118 and 119:

VISIONS FEDERAL CREDIT UNION Thomas

- Page 120 and 121:

VISIONS FEDERAL CREDIT UNION 120 or

- Page 122 and 123:

VISIONS FEDERAL CREDIT UNION 122

- Page 124 and 125:

What does it mean to innovate in ba

- Page 126 and 127:

VISIONS FEDERAL CREDIT UNION Are th

- Page 128 and 129:

VISIONS FEDERAL CREDIT UNION 128 it

- Page 130 and 131:

130 DECEMBER 2019

- Page 132 and 133:

RANDALL CONSTRUCTION RANDALL Constr

- Page 134 and 135:

RANDALL CONSTRUCTION 134 “The mor

- Page 136 and 137:

Done right the first time, On Time

- Page 138 and 139:

RANDALL CONSTRUCTION formed partner

- Page 140 and 141:

Advanced Enviromental Systems AES C

- Page 142 and 143:

RANDALL CONSTRUCTION 142 “Our inn

- Page 144 and 145:

144 PEPSICO LATAM: DRIVING INNOVATI

- Page 146 and 147:

PEPSICO PEPSICO LATAM HAS BEEN UNDE

- Page 148 and 149:

PEPSICO 148 “THE FIRM’S STRONG

- Page 150 and 151:

We transport your future Tomorrow

- Page 152 and 153:

We are your Warehouse Logistics Sol

- Page 154 and 155:

PEPSICO 154 and more. Focusing on s

- Page 156 and 157:

PEPSICO 156 DECEMBER 2019

- Page 158 and 159:

158 Seamless customer journeys and

- Page 160 and 161:

WSIB Samantha Liscio, Chief Technol

- Page 162 and 163:

WSIB 162 “Our CEO affirms that ou

- Page 166 and 167:

WSIB 166 “With a clear focus on w

- Page 169 and 170:

CLICK TO WATCH: ‘PETE’S RETURN-

- Page 171 and 172: digitally-enabled insurance tools t

- Page 173 and 174: CLICK TO WATCH: ‘DOUG’S RETURN-

- Page 175 and 176: 175 been enabled by this structural

- Page 177 and 178: payment cycle to deliver has become

- Page 179 and 180: www.businesschief.com 179

- Page 181 and 182: 181 2005 Year founded 2,000 Approxi

- Page 183 and 184: CLICK TO WATCH: ‘MOTUSBANK: OUR S

- Page 185 and 186: 185 EXECUTIVE PROFILE David Baldere

- Page 187 and 188: member experience and national stra

- Page 189 and 190: www.businesschief.com 189

- Page 191 and 192: efficiently, making it possible to

- Page 193 and 194: Motusbank has given MCU a reliable

- Page 195 and 196: www.businesschief.com 195

- Page 197 and 198: www.businesschief.com 197

- Page 199 and 200: CLICK TO WATCH: ‘KUBRA EXPERIENCE

- Page 201 and 202: “While secure delivery of new pro

- Page 203 and 204: 203 a relationship where the partne

- Page 205 and 206: chose to work with offers stateless

- Page 207 and 208: 1992 Year founded 500 Number of emp

- Page 209 and 210: www.businesschief.com 209

- Page 211 and 212: www.businesschief.com 211

- Page 213 and 214: CLICK TO WATCH: ‘DRA GLOBAL OVERV

- Page 215 and 216: Mineral: Chalcopyrite Particle Size

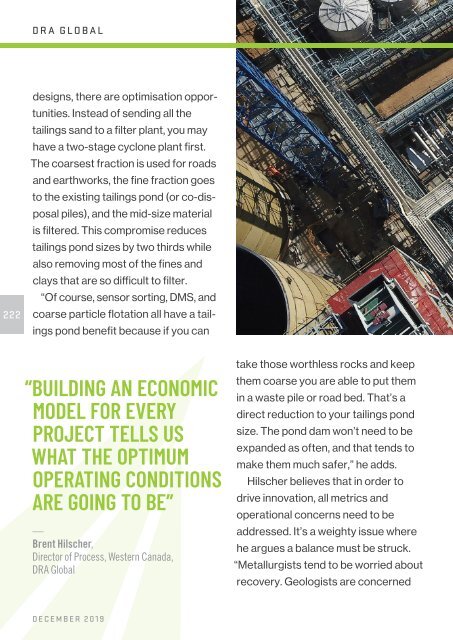

- Page 217 and 218: Preparing an economic model for eac

- Page 219 and 220: “METALLURGISTS TEND TO BE WORRIED

- Page 221: 221 Hydrofloat is a new coarse part

- Page 225 and 226: State-ofthe-art data centers in Can

- Page 227 and 228: 227 2017 Year founded 60 Number of

- Page 229 and 230: CLICK TO WATCH: ‘ESTRUXTURE SHARE

- Page 231 and 232: 231 Todd Coleman EXECUTIVE PROFILE

- Page 233 and 234: www.businesschief.com 233

- Page 235 and 236: “Our engineers work to design and

- Page 237: eStruxture is confident in the path