VGB POWERTECH 7 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Optimisation of power plants. Thermal waste utilisation.

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Optimisation of power plants. Thermal waste utilisation.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>VGB</strong> PowerTech 7 l <strong>2021</strong><br />

Digital trans<strong>for</strong>mation <strong>of</strong> the coal sector<br />

Digital trans<strong>for</strong>mation<br />

<strong>of</strong> the coal sector<br />

The future intelligent power generation enterprise<br />

will be a data-driven (F i g u r e 3 ),<br />

Cloud-enabled enterprise in which decisions<br />

in all areas <strong>of</strong> the business are in<strong>for</strong>med<br />

by live streams <strong>of</strong> data <strong>and</strong> connected<br />

by a single digital plat<strong>for</strong>m at plant or<br />

fleet level. The digital plat<strong>for</strong>m will be connected<br />

to almost everything from energy<br />

production <strong>and</strong> transport, power generation,<br />

transmission <strong>and</strong> distribution (T&D),<br />

sales <strong>and</strong> services, <strong>and</strong> beyond. The digital<br />

plat<strong>for</strong>m can run complex power generation<br />

operations efficiently, leading to optimal<br />

operational <strong>and</strong> environmental per<strong>for</strong>mance,<br />

improved flexibility, reliability, security<br />

<strong>and</strong> pr<strong>of</strong>itability. Digital technologies<br />

can also be applied to coal mining, helping<br />

to automate <strong>and</strong> optimise coal production,<br />

improve operational efficiency, environmental<br />

per<strong>for</strong>mance, workers’ safety <strong>and</strong><br />

production workflow at reduced costs.<br />

Benefits <strong>of</strong> digitalising<br />

power generation<br />

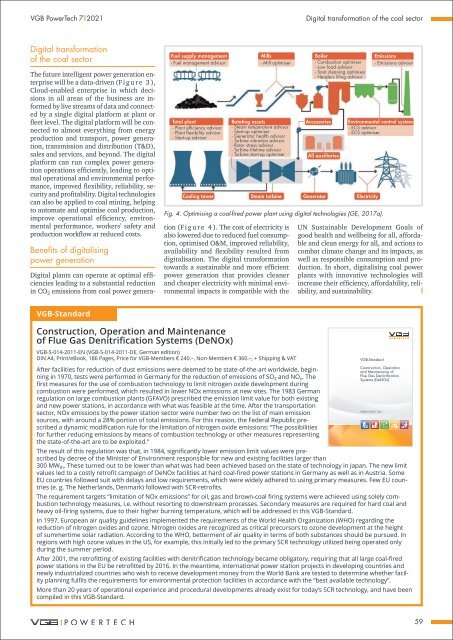

Fuel supply management Mills Boiler Emissions<br />

- Fuel management advisor - Mill optimiser - Combustion optimiser - Emissions advisor<br />

- Low load advisor<br />

- Soot cleaning optimiser<br />

- Headers lifing advisor<br />

Total plant Rotating assets Accessories Environmental control system<br />

- Plant efficiency advisor - Steam temperature advisor<br />

- ECS advisor<br />

- Plant flexibility advisor - Start-up optimiser<br />

- ECS optimiser<br />

- Start-up advisor<br />

- Generator health advisor<br />

- Turbine vibration advisor<br />

- Rotor stress advisor<br />

- Turbine lifetime advisor<br />

- Turbine start-up optimiser All auxiliaries<br />

Cooling tower Steam turbine Generator <strong>Electricity</strong><br />

Fig. 4. Optimising a coal-fired power plant using digital technologies (GE, 2017a).<br />

Digital plants can operate at optimal efficiencies<br />

leading to a substantial reduction<br />

in CO 2 emissions from coal power generation<br />

(F i g u r e 4 ). The cost <strong>of</strong> electricity is<br />

also lowered due to reduced fuel consumption,<br />

optimised O&M, improved reliability,<br />

availability <strong>and</strong> flexibility resulted from<br />

digitalisation. The digital trans<strong>for</strong>mation<br />

towards a sustainable <strong>and</strong> more efficient<br />

power generation that provides cleaner<br />

<strong>and</strong> cheaper electricity with minimal environmental<br />

impacts is compatible with the<br />

UN Sustainable Development Goals <strong>of</strong><br />

good health <strong>and</strong> wellbeing <strong>for</strong> all, af<strong>for</strong>dable<br />

<strong>and</strong> clean energy <strong>for</strong> all, <strong>and</strong> actions to<br />

combat climate change <strong>and</strong> its impacts, as<br />

well as responsible consumption <strong>and</strong> production.<br />

In short, digitalising coal power<br />

plants with innovative technologies will<br />

increase their efficiency, af<strong>for</strong>dability, reliability,<br />

<strong>and</strong> sustainability.<br />

l<br />

<strong>VGB</strong>-St<strong>and</strong>ard<br />

Construction, Operation <strong>and</strong> Maintenance<br />

<strong>of</strong> Flue Gas Denitrification Systems (DeNOx)<br />

<strong>VGB</strong>-S-014-2011-EN (<strong>VGB</strong>-S-014-2011-DE, German edition)<br />

DIN A4, Print/eBook, 186 Pages, Price <strong>for</strong> <strong>VGB</strong>-Members € 240.–, Non-Members € 360.–, + Shipping & VAT<br />

After facilities <strong>for</strong> reduction <strong>of</strong> dust emissions were deemed to be state-<strong>of</strong>-the-art worldwide, beginning<br />

in 1970, tests were per<strong>for</strong>med in Germany <strong>for</strong> the reduction <strong>of</strong> emissions <strong>of</strong> SO 2 <strong>and</strong> NO x . The<br />

first measures <strong>for</strong> the use <strong>of</strong> combustion technology to limit nitrogen oxide development during<br />

combustion were per<strong>for</strong>med, which resulted in lower NOx emissions at new sites. The 1983 German<br />

regulation on large combustion plants (GFAVO) prescribed the emission limit value <strong>for</strong> both existing<br />

<strong>and</strong> new power stations, in accordance with what was feasible at the time. After the transportation<br />

sector, NOx emissions by the power station sector were number two on the list <strong>of</strong> main emission<br />

sources, with around a 28% portion <strong>of</strong> total emissions. For this reason, the Federal Republic prescribed<br />

a dynamic modification rule <strong>for</strong> the limitation <strong>of</strong> nitrogen oxide emissions: “The possibilities<br />

<strong>for</strong> further reducing emissions by means <strong>of</strong> combustion technology or other measures representing<br />

the state-<strong>of</strong>-the-art are to be exploited.”<br />

<strong>VGB</strong>-St<strong>and</strong>ard<br />

Construction, Operation<br />

<strong>and</strong> Maintenance <strong>of</strong><br />

Flue Gas Denitrification<br />

Systems (DeNOx)<br />

<strong>VGB</strong>-S-014-2011-EN<br />

The result <strong>of</strong> this regulation was that, in 1984, significantly lower emission limit values were prescribed<br />

by decree <strong>of</strong> the Minister <strong>of</strong> Environment responsible <strong>for</strong> new <strong>and</strong> existing facilities larger than<br />

300 MW th . These turned out to be lower than what was had been achieved based on the state <strong>of</strong> technology in Japan. The new limit<br />

values led to a costly retr<strong>of</strong>it campaign <strong>of</strong> DeNOx facilities at hard coal-fired power stations in Germany as well as in Austria. Some<br />

EU countries followed suit with delays <strong>and</strong> low requirements, which were widely adhered to using primary measures. Few EU countries<br />

(e. g. The Netherl<strong>and</strong>s, Denmark) followed with SCR-retr<strong>of</strong>its.<br />

The requirement targets “limitation <strong>of</strong> NOx emissions” <strong>for</strong> oil, gas <strong>and</strong> brown-coal firing systems were achieved using solely combustion<br />

technology measures, i.e. without resorting to downstream processes. Secondary measures are required <strong>for</strong> hard coal <strong>and</strong><br />

heavy oil-firing systems, due to their higher burning temperature, which will be addressed in this <strong>VGB</strong>-St<strong>and</strong>ard.<br />

In 1997, European air quality guidelines implemented the requirements <strong>of</strong> the World Health Organization (WHO) regarding the<br />

reduction <strong>of</strong> nitrogen oxides <strong>and</strong> ozone. Nitrogen oxides are recognized as critical precursors to ozone development at the height<br />

<strong>of</strong> summertime solar radiation. According to the WHO, betterment <strong>of</strong> air quality in terms <strong>of</strong> both substances should be pursued. In<br />

regions with high ozone values in the US, <strong>for</strong> example, this initially led to the primary SCR technology utilized being operated only<br />

during the summer period.<br />

After 2001, the retr<strong>of</strong>itting <strong>of</strong> existing facilities with denitrification technology became obligatory, requiring that all large coal-fired<br />

power stations in the EU be retr<strong>of</strong>itted by 2016. In the meantime, international power station projects in developing countries <strong>and</strong><br />

newly industrialized countries who wish to receive development money from the World Bank are tested to determine whether facility<br />

planning fulfils the requirements <strong>for</strong> environmental protection facilities in accordance with the “best available technology”.<br />

More than 20 years <strong>of</strong> operational experience <strong>and</strong> procedural developments already exist <strong>for</strong> today’s SCR technology, <strong>and</strong> have been<br />

compiled in this <strong>VGB</strong>-St<strong>and</strong>ard.<br />

59