VGB POWERTECH 7 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Optimisation of power plants. Thermal waste utilisation.

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Optimisation of power plants. Thermal waste utilisation.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>VGB</strong> PowerTech 7 l <strong>2021</strong><br />

Avoid cost-intensive oil change in a hydropower plant<br />

<strong>VGB</strong> oil laboratory tests oil blends to<br />

avoid cost-intensive oil change in a<br />

hydropower plant<br />

Kurzfassung<br />

Ölmischbarkeitsversuche im <strong>VGB</strong>-Öllabor<br />

vermeiden kostenintensiven Ölwechsel<br />

Die Energiewende und die damit verbundene<br />

vorrangige Einspeisung erneuerbarer Energie<br />

er<strong>for</strong>dert von konventionellen, disponiblen Erzeugungsanlagen<br />

ein hohes Maß an Flexibilität.<br />

Wasserkraft als erneuerbarer Energieträger<br />

zeichnet sich durch die Rund-um-die-Uhr-Verfügbarkeit<br />

und Planbarkeit als eine verlässliche<br />

Größe in der Energieversorgung aus. Wasserkraftwerke,<br />

bzw. deren Komponenten wie Turbine<br />

und Hydrauliksysteme sowie Antriebe für<br />

Tore, Schieber und Klappen, benötigen wie alle<br />

Kraftwerke und Windkraftanlagen große Mengen<br />

an Schmierölen und Schmierst<strong>of</strong>fen. Die<br />

Überprüfung dieser St<strong>of</strong>fe hat einen ganz besonderen<br />

Stellenwert. Die regelmäßige Kontrolle,<br />

und dadurch frühzeitiges Erkennen von Anlagenstörungen<br />

und sich anbahnenden Schäden,<br />

gewährleisten den sicheren und reibungslosen<br />

Betrieb der Wasserkraftwerke. Ein vollständiger<br />

Ölwechsel, der nur bei Anlagenstillst<strong>and</strong><br />

durchgeführt werden kann, ist mit einem<br />

hohen Kosten- und Personalaufw<strong>and</strong> verbunden.<br />

Er ist daher nicht das erste Mittel der Wahl.<br />

Das <strong>VGB</strong>-Öllabor unterstüzt die <strong>VGB</strong>-Mitglieder<br />

und Kunden bei der Identifikation von Ölen, die<br />

sich mit den noch im Betrieb befindlichen Ölen<br />

mischen lassen und dabei den sicheren und zuverlässigen<br />

weiteren Anlagenbetrieb ermöglichen.<br />

l<br />

The energy transition <strong>and</strong> the associated<br />

priority feed-in <strong>of</strong> renewable energy require<br />

a high degree <strong>of</strong> flexibility from conventional,<br />

plannable generation plants,<br />

which is <strong>of</strong>ten associated with serious<br />

problems due to the design <strong>of</strong> conventional<br />

thermal power plants (frequent load<br />

changes, start-up <strong>and</strong> shut-down, etc.). In<br />

contrast to volatile renewables (wind <strong>and</strong><br />

solar), hydropower is a renewable source<br />

<strong>of</strong> energy that is reliably supplying power<br />

due to its base load capability <strong>and</strong> plannability,<br />

i.e., some <strong>of</strong> the most important requirements<br />

– namely security <strong>of</strong> supply <strong>and</strong><br />

system stability – are met by hydropower.<br />

Service <strong>for</strong> oil ensures safe<br />

operation<br />

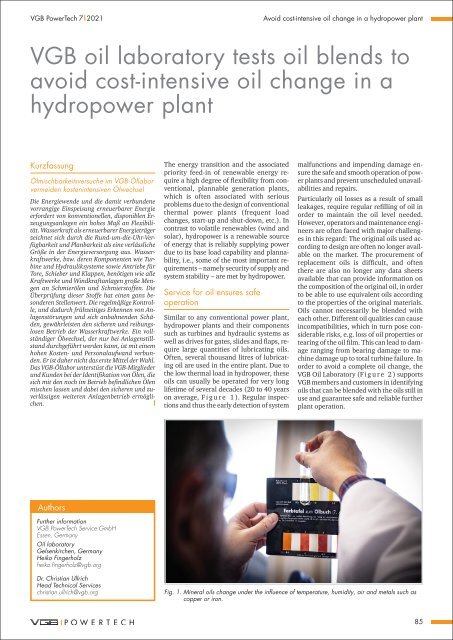

Similar to any conventional power plant,<br />

hydropower plants <strong>and</strong> their components<br />

such as turbines <strong>and</strong> hydraulic systems as<br />

well as drives <strong>for</strong> gates, slides <strong>and</strong> flaps, require<br />

large quantities <strong>of</strong> lubricating oils.<br />

Often, several thous<strong>and</strong> litres <strong>of</strong> lubricating<br />

oil are used in the entire plant. Due to<br />

the low thermal load in hydropower, these<br />

oils can usually be operated <strong>for</strong> very long<br />

lifetime <strong>of</strong> several decades (20 to 40 years<br />

on average, F i g u r e 1 ). Regular inspections<br />

<strong>and</strong> thus the early detection <strong>of</strong> system<br />

malfunctions <strong>and</strong> impending damage ensure<br />

the safe <strong>and</strong> smooth operation <strong>of</strong> power<br />

plants <strong>and</strong> prevent unscheduled unavailabilities<br />

<strong>and</strong> repairs.<br />

Particularly oil losses as a result <strong>of</strong> small<br />

leakages, require regular refilling <strong>of</strong> oil in<br />

order to maintain the oil level needed.<br />

However, operators <strong>and</strong> maintenance engineers<br />

are <strong>of</strong>ten faced with major challenges<br />

in this regard: The original oils used according<br />

to design are <strong>of</strong>ten no longer available<br />

on the market. The procurement <strong>of</strong><br />

replacement oils is difficult, <strong>and</strong> <strong>of</strong>ten<br />

there are also no longer any data sheets<br />

available that can provide in<strong>for</strong>mation on<br />

the composition <strong>of</strong> the original oil, in order<br />

to be able to use equivalent oils according<br />

to the properties <strong>of</strong> the original materials.<br />

Oils cannot necessarily be blended with<br />

each other. Different oil qualities can cause<br />

incompatibilities, which in turn pose considerable<br />

risks, e.g. loss <strong>of</strong> oil properties or<br />

tearing <strong>of</strong> the oil film. This can lead to damage<br />

ranging from bearing damage to machine<br />

damage up to total turbine failure. In<br />

order to avoid a complete oil change, the<br />

<strong>VGB</strong> Oil Laboratory (F i g u r e 2 ) supports<br />

<strong>VGB</strong> members <strong>and</strong> customers in identifying<br />

oils that can be blended with the oils still in<br />

use <strong>and</strong> guarantee safe <strong>and</strong> reliable further<br />

plant operation.<br />

Authors<br />

Further in<strong>for</strong>mation<br />

<strong>VGB</strong> PowerTech Service GmbH<br />

Essen, Germany<br />

Oil laboratory<br />

Gelsenkirchen, Germany<br />

Heiko Fingerholz<br />

heiko.fingerholz@vgb.org<br />

Dr. Christian Ullrich<br />

Head Technical Services<br />

christian.ullrich@vgb.org<br />

Fig. 1. Mineral oils change under the influence <strong>of</strong> temperature, humidity, air <strong>and</strong> metals such as<br />

copper or iron.<br />

85