VGB POWERTECH 7 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Optimisation of power plants. Thermal waste utilisation.

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Optimisation of power plants. Thermal waste utilisation.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Verification <strong>of</strong> SPACE code based on an MSGTR experiment at the ATLAS-PAFS facility <strong>VGB</strong> PowerTech 7 l <strong>2021</strong><br />

Tab. 2. Sequence <strong>of</strong> transient analysis result.<br />

Event Experiment (t = t*) SPACE code (t = t*) Remarks<br />

MSGTR initiation 0.0000 0.0000<br />

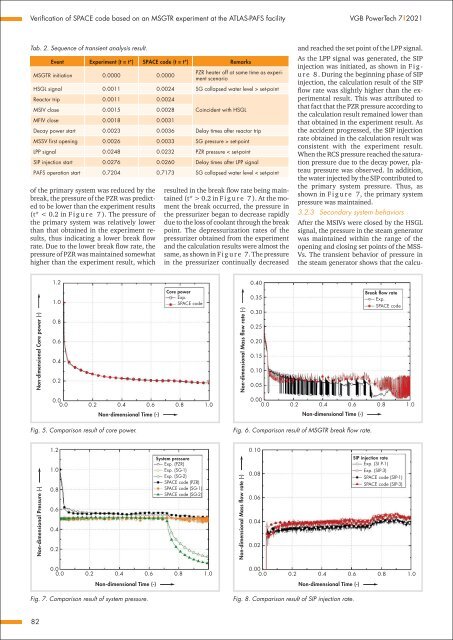

<strong>of</strong> the primary system was reduced by the<br />

break, the pressure <strong>of</strong> the PZR was predicted<br />

to be lower than the experiment results<br />

(t* < 0.2 in F i g u r e 7 ). The pressure <strong>of</strong><br />

the primary system was relatively lower<br />

than that obtained in the experiment results,<br />

thus indicating a lower break flow<br />

rate. Due to the lower break flow rate, the<br />

pressure <strong>of</strong> PZR was maintained somewhat<br />

higher than the experiment result, which<br />

PZR heater <strong>of</strong>f at same time as experiment<br />

scenario<br />

HSGL signal 0.0011 0.0024 SG collapsed water level > set-point<br />

Reactor trip 0.0011 0.0024<br />

MSIV close 0.0015 0.0028<br />

MFIV close 0.0018 0.0031<br />

Coincident with HSGL<br />

Decay power start 0.0023 0.0036 Delay times after reactor trip<br />

MSSV first opening 0.0026 0.0033 SG pressure > set-point<br />

LPP signal 0.0248 0.0232 PZR pressure < set-point<br />

SIP injection start 0.0276 0.0260 Delay times after LPP signal<br />

PAFS operation start 0.7204 0.7173 SG collapsed water level < set-point<br />

resulted in the break flow rate being maintained<br />

(t* > 0.2 in F i g u r e 7 ). At the moment<br />

the break occurred, the pressure in<br />

the pressurizer began to decrease rapidly<br />

due to the loss <strong>of</strong> coolant through the break<br />

point. The depressurization rates <strong>of</strong> the<br />

pressurizer obtained from the experiment<br />

<strong>and</strong> the calculation results were almost the<br />

same, as shown in F i g u r e 7. The pressure<br />

in the pressurizer continually decreased<br />

<strong>and</strong> reached the set point <strong>of</strong> the LPP signal.<br />

As the LPP signal was generated, the SIP<br />

injection was initiated, as shown in F i g -<br />

u r e 8 . During the beginning phase <strong>of</strong> SIP<br />

injection, the calculation result <strong>of</strong> the SIP<br />

flow rate was slightly higher than the experimental<br />

result. This was attributed to<br />

that fact that the PZR pressure according to<br />

the calculation result remained lower than<br />

that obtained in the experiment result. As<br />

the accident progressed, the SIP injection<br />

rate obtained in the calculation result was<br />

consistent with the experiment result.<br />

When the RCS pressure reached the saturation<br />

pressure due to the decay power, plateau<br />

pressure was observed. In addition,<br />

the water injected by the SIP contributed to<br />

the primary system pressure. Thus, as<br />

shown in F i g u r e 7, the primary system<br />

pressure was maintained.<br />

3.2.3 Secondary system behaviors<br />

After the MSIVs were closed by the HSGL<br />

signal, the pressure in the steam generator<br />

was maintained within the range <strong>of</strong> the<br />

opening <strong>and</strong> closing set points <strong>of</strong> the MSS-<br />

Vs. The transient behavior <strong>of</strong> pressure in<br />

the steam generator shows that the calcu-<br />

1.2<br />

0.40<br />

Non-dimensional Core power (-)<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

Core power<br />

Exp.<br />

SPACE code<br />

Non-dimensional Mass flow rate (-)<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

Break flow rate<br />

Exp.<br />

SPACE code<br />

0.0<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

Non-dimensional Time (-)<br />

Fig. 5. Comparison result <strong>of</strong> core power.<br />

0.00<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

Non-dimensional Time (-)<br />

Fig. 6. Comparison result <strong>of</strong> MSGTR break flow rate.<br />

Non-dimensional Pressure (-)<br />

1.2<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

System pressure<br />

Exp. (PZR)<br />

Exp. (SG-1)<br />

Exp. (SG-2)<br />

SPACE code (PZR)<br />

SPACE code (SG-1)<br />

SPACE code (SG-2)<br />

Non-dimensional Mass flow rate (-)<br />

0.10<br />

0.08<br />

0.06<br />

0.04<br />

0.02<br />

SIP injection rate<br />

Exp. (SI P-1)<br />

Exp. (SIP-3)<br />

SPACE code (SIP-1)<br />

SPACE code (SIP-3)<br />

0.0<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

Non-dimensional Time (-)<br />

Fig. 7. Comparison result <strong>of</strong> system pressure.<br />

0.00<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

Non-dimensional Time (-)<br />

Fig. 8. Comparison result <strong>of</strong> SIP injection rate.<br />

82