VGB POWERTECH 7 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Optimisation of power plants. Thermal waste utilisation.

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Optimisation of power plants. Thermal waste utilisation.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>VGB</strong> PowerTech 7 l <strong>2021</strong><br />

Study on the integrity <strong>of</strong> containment against hydrogen threats<br />

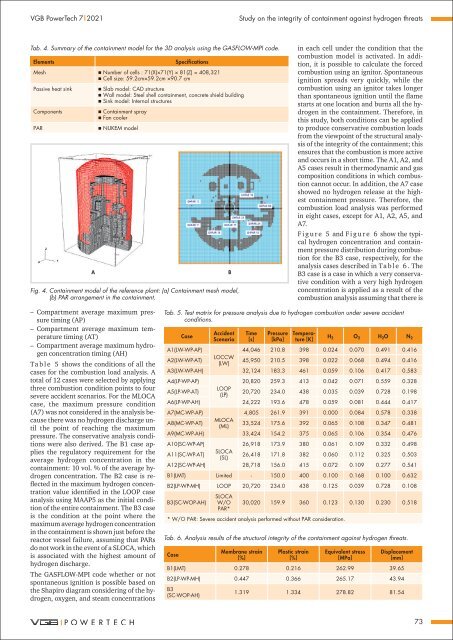

Tab. 4. Summary <strong>of</strong> the containment model <strong>for</strong> the 3D analysis using the GASFLOW-MPI code.<br />

Elements<br />

Specifications<br />

Mesh Number <strong>of</strong> cells : 71(X)×71(Y) × 81(Z) = 408,321<br />

Cell size: 59.2cm×59.2cm ×90.7 cm<br />

Passive heat sink<br />

Components<br />

PAR<br />

A<br />

Slab model: CAD structure<br />

Wall model: Steel shell containment, concrete shield building<br />

Sink model: Internal structures<br />

Containment spray<br />

Fan cooler<br />

NUKEM model<br />

Fig. 4. Containment model <strong>of</strong> the reference plant: (a) Containment mesh model,<br />

(b) PAR arrangement in the containment.<br />

B<br />

in each cell under the condition that the<br />

combustion model is activated. In addition,<br />

it is possible to calculate the <strong>for</strong>ced<br />

combustion using an ignitor. Spontaneous<br />

ignition spreads very quickly, while the<br />

combustion using an ignitor takes longer<br />

than spontaneous ignition until the flame<br />

starts at one location <strong>and</strong> burns all the hydrogen<br />

in the containment. There<strong>for</strong>e, in<br />

this study, both conditions can be applied<br />

to produce conservative combustion loads<br />

from the viewpoint <strong>of</strong> the structural analysis<br />

<strong>of</strong> the integrity <strong>of</strong> the containment; this<br />

ensures that the combustion is more active<br />

<strong>and</strong> occurs in a short time. The A1, A2, <strong>and</strong><br />

A5 cases result in thermodynamic <strong>and</strong> gas<br />

composition conditions in which combustion<br />

cannot occur. In addition, the A7 case<br />

showed no hydrogen release at the highest<br />

containment pressure. There<strong>for</strong>e, the<br />

combustion load analysis was per<strong>for</strong>med<br />

in eight cases, except <strong>for</strong> A1, A2, A5, <strong>and</strong><br />

A7.<br />

F i g u r e 5 <strong>and</strong> F i g u r e 6 show the typical<br />

hydrogen concentration <strong>and</strong> containment<br />

pressure distribution during combustion<br />

<strong>for</strong> the B3 case, respectively, <strong>for</strong> the<br />

analysis cases described in Ta b l e 6 . The<br />

B3 case is a case in which a very conservative<br />

condition with a very high hydrogen<br />

concentration is applied as a result <strong>of</strong> the<br />

combustion analysis assuming that there is<br />

––<br />

Compartment average maximum pressure<br />

timing (AP)<br />

––<br />

Compartment average maximum temperature<br />

timing (AT)<br />

––<br />

Compartment average maximum hydrogen<br />

concentration timing (AH)<br />

Ta b l e 5 shows the conditions <strong>of</strong> all the<br />

cases <strong>for</strong> the combustion load analysis. A<br />

total <strong>of</strong> 12 cases were selected by applying<br />

three combustion condition points to four<br />

severe accident scenarios. For the MLOCA<br />

case, the maximum pressure condition<br />

(A7) was not considered in the analysis because<br />

there was no hydrogen discharge until<br />

the point <strong>of</strong> reaching the maximum<br />

pressure. The conservative analysis conditions<br />

were also derived. The B1 case applies<br />

the regulatory requirement <strong>for</strong> the<br />

average hydrogen concentration in the<br />

containment: 10 vol. % <strong>of</strong> the average hydrogen<br />

concentration. The B2 case is reflected<br />

in the maximum hydrogen concentration<br />

value identified in the LOOP case<br />

analysis using MAAP5 as the initial condition<br />

<strong>of</strong> the entire containment. The B3 case<br />

is the condition at the point where the<br />

maximum average hydrogen concentration<br />

in the containment is shown just be<strong>for</strong>e the<br />

reactor vessel failure, assuming that PARs<br />

do not work in the event <strong>of</strong> a SLOCA, which<br />

is associated with the highest amount <strong>of</strong><br />

hydrogen discharge.<br />

The GASFLOW-MPI code whether or not<br />

spontaneous ignition is possible based on<br />

the Shapiro diagram considering <strong>of</strong> the hydrogen,<br />

oxygen, <strong>and</strong> steam concentrations<br />

Tab. 5. Test matrix <strong>for</strong> pressure analysis due to hydrogen combustion under severe accident<br />

conditions.<br />

Case<br />

Accident<br />

Scenario<br />

Time<br />

[s]<br />

Pressure<br />

[kPa]<br />

Temperature<br />

[K]<br />

H 2 O 2 H 2 O N 2<br />

A1(LW-WP-AP)<br />

44,046 210.8 398 0.024 0.070 0.491 0.416<br />

A2(LW-WP-AT)<br />

LOCCW<br />

(LW)<br />

45,950 210.5 398 0.022 0.068 0.494 0.416<br />

A3(LW-WP-AH) 32,124 183.3 461 0.059 0.106 0.417 0.583<br />

A4(LP-WP-AP)<br />

20,820 259.3 413 0.042 0.071 0.559 0.328<br />

A5(LP-WP-AT)<br />

LOOP<br />

(LP)<br />

20,720 234.0 438 0.035 0.039 0.728 0.198<br />

A6(LP-WP-AH) 24,222 193.6 478 0.059 0.081 0.444 0.417<br />

A7(MC-WP-AP)<br />

4,805 261.9 391 0.000 0.084 0.578 0.338<br />

A8(MC-WP-AT)<br />

MLOCA<br />

(ML)<br />

33,524 175.6 392 0.065 0.108 0.347 0.481<br />

A9(MC-WP-AH) 33,424 154.2 375 0.065 0.106 0.354 0.476<br />

A10(SC-WP-AP)<br />

26,918 173.9 380 0.061 0.109 0.332 0.498<br />

A11(SC-WP-AT)<br />

SLOCA<br />

(SL)<br />

26,418 171.8 382 0.060 0.112 0.325 0.503<br />

A12(SC-WP-AH) 28,718 156.0 415 0.072 0.109 0.277 0.541<br />

B1(LMT) Limited - 150.0 400 0.100 0.168 0.100 0.632<br />

B2(LP-WP-MH) LOOP 20,720 234.0 438 0.125 0.039 0.728 0.108<br />

B3(SC-WOP-AH)<br />

SLOCA<br />

W/O<br />

PAR*<br />

30,020 159.9 360 0.123 0.130 0.230 0.518<br />

* W/O PAR: Severe accident analysis per<strong>for</strong>med without PAR consideration.<br />

Tab. 6. Analysis results <strong>of</strong> the structural integrity <strong>of</strong> the containment against hydrogen threats.<br />

Case<br />

Membrane strain<br />

[%]<br />

Plastic strain<br />

[%]<br />

Equivalent stress<br />

[MPa]<br />

Displacement<br />

[mm]<br />

B1(LMT) 0.278 0.216 262.99 39.65<br />

B2(LP-WP-MH) 0.447 0.366 265.17 43.94<br />

B3<br />

(SC-WOP-AH)<br />

1.319 1.334 278.82 81.54<br />

73