VGB POWERTECH 7 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Optimisation of power plants. Thermal waste utilisation.

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Optimisation of power plants. Thermal waste utilisation.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>VGB</strong> PowerTech 7 l <strong>2021</strong><br />

Study on the integrity <strong>of</strong> containment against hydrogen threats<br />

5. Conclusion<br />

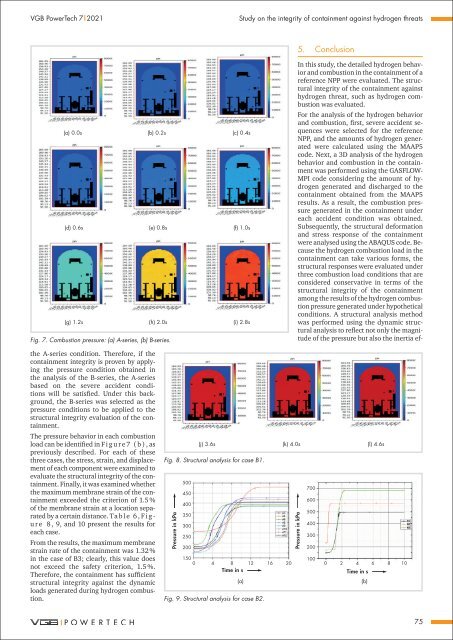

(a) 0.0s (b) 0.2s (c) 0.4s<br />

(d) 0.6s (e) 0.8s (f) 1.0s<br />

(g) 1.2s (h) 2.0s<br />

(i) 2.8s<br />

Fig. 7. Combustion pressure: (a) A-series, (b) B-series.<br />

In this study, the detailed hydrogen behavior<br />

<strong>and</strong> combustion in the containment <strong>of</strong> a<br />

reference NPP were evaluated. The structural<br />

integrity <strong>of</strong> the containment against<br />

hydrogen threat, such as hydrogen combustion<br />

was evaluated.<br />

For the analysis <strong>of</strong> the hydrogen behavior<br />

<strong>and</strong> combustion, first, severe accident sequences<br />

were selected <strong>for</strong> the reference<br />

NPP, <strong>and</strong> the amounts <strong>of</strong> hydrogen generated<br />

were calculated using the MAAP5<br />

code. Next, a 3D analysis <strong>of</strong> the hydrogen<br />

behavior <strong>and</strong> combustion in the containment<br />

was per<strong>for</strong>med using the GASFLOW-<br />

MPI code considering the amount <strong>of</strong> hydrogen<br />

generated <strong>and</strong> discharged to the<br />

containment obtained from the MAAP5<br />

results. As a result, the combustion pressure<br />

generated in the containment under<br />

each accident condition was obtained.<br />

Subsequently, the structural de<strong>for</strong>mation<br />

<strong>and</strong> stress response <strong>of</strong> the containment<br />

were analysed using the ABAQUS code. Because<br />

the hydrogen combustion load in the<br />

containment can take various <strong>for</strong>ms, the<br />

structural responses were evaluated under<br />

three combustion load conditions that are<br />

considered conservative in terms <strong>of</strong> the<br />

structural integrity <strong>of</strong> the containment<br />

among the results <strong>of</strong> the hydrogen combustion<br />

pressure generated under hypothetical<br />

conditions. A structural analysis method<br />

was per<strong>for</strong>med using the dynamic structural<br />

analysis to reflect not only the magnitude<br />

<strong>of</strong> the pressure but also the inertia ef-<br />

the A-series condition. There<strong>for</strong>e, if the<br />

containment integrity is proven by applying<br />

the pressure condition obtained in<br />

the analysis <strong>of</strong> the B-series, the A-series<br />

based on the severe accident conditions<br />

will be satisfied. Under this background,<br />

the B-series was selected as the<br />

pressure conditions to be applied to the<br />

structural integrity evaluation <strong>of</strong> the containment.<br />

The pressure behavior in each combustion<br />

load can be identified in F i g u r e 7 ( b ) , as<br />

previously described. For each <strong>of</strong> these<br />

three cases, the stress, strain, <strong>and</strong> displacement<br />

<strong>of</strong> each component were examined to<br />

evaluate the structural integrity <strong>of</strong> the containment.<br />

Finally, it was examined whether<br />

the maximum membrane strain <strong>of</strong> the containment<br />

exceeded the criterion <strong>of</strong> 1.5 %<br />

<strong>of</strong> the membrane strain at a location separated<br />

by a certain distance. Ta b l e 6 , F i g -<br />

u r e 8 , 9, <strong>and</strong> 10 present the results <strong>for</strong><br />

each case.<br />

From the results, the maximum membrane<br />

strain rate <strong>of</strong> the containment was 1.32 %<br />

in the case <strong>of</strong> B3; clearly, this value does<br />

not exceed the safety criterion, 1.5 %.<br />

There<strong>for</strong>e, the containment has sufficient<br />

structural integrity against the dynamic<br />

loads generated during hydrogen combustion.<br />

(j) 3.6s (k) 4.0s (l) 4.6s<br />

Fig. 8. Structural analysis <strong>for</strong> case B1.<br />

500<br />

700<br />

450<br />

600<br />

400<br />

Pressure in kPa<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

0 4 8 12 16 20 0 2 4 6 8 10<br />

Time in s<br />

Time in s<br />

(a)<br />

(b)<br />

Fig. 9. Structural analysis <strong>for</strong> case B2.<br />

Pressure in kPa<br />

500<br />

400<br />

300<br />

200<br />

75