Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

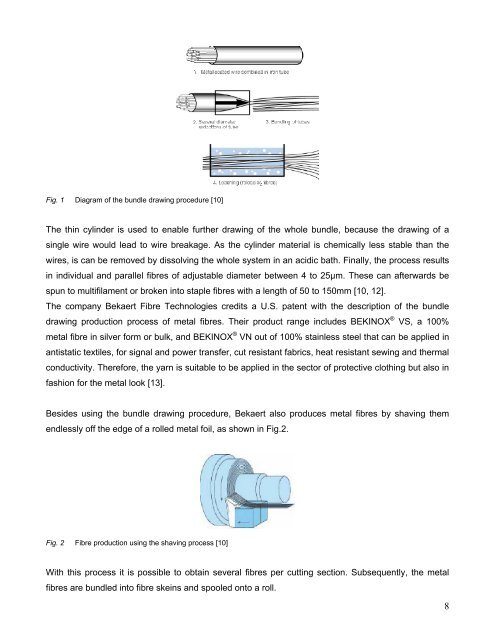

Fig. 1 Diagram of the bundle drawing procedure [10]<br />

The thin cylinder is used to enable further drawing of the whole bundle, because the drawing of a<br />

single wire would lead to wire breakage. As the cylinder material is chemically less stable than the<br />

wires, is can be removed by dissolving the whole system in an acidic bath. Finally, the process results<br />

in individual and parallel fibres of adjustable diameter between 4 to 25µm. These can afterwards be<br />

spun to multifilament or broken into staple fibres with a length of 50 to 150mm [10, 12].<br />

The company Bekaert Fibre Technologies credits a U.S. patent with the description of the bundle<br />

drawing production process of metal fibres. Their product range includes BEKINOX ® VS, a 100%<br />

metal fibre in silver form or bulk, and BEKINOX ® VN out of 100% stainless steel that can be applied in<br />

antistatic textiles, for signal and power transfer, cut resistant fabrics, heat resistant sewing and thermal<br />

conductivity. Therefore, the yarn is suitable to be applied in the sector of protective clothing but also in<br />

fashion for the metal look [13].<br />

Besides using the bundle drawing procedure, Bekaert also produces metal fibres by shaving them<br />

endlessly off the edge of a rolled metal foil, as shown in Fig.2.<br />

Fig. 2 Fibre production using the shaving process [10]<br />

With this process it is possible to obtain several fibres per cutting section. Subsequently, the metal<br />

fibres are bundled into fibre skeins and spooled onto a roll.<br />

8