Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

problem should be taken care of at young age. It is not self-evident however to impose the child to a<br />

strict schedule of periods it has to wear the eye patch. The attending doctor has to completely rely on<br />

the information the parents have given him on the subject. Nevertheless, wearing the eye patch on<br />

prescribed periods of time is of crucial importance for the therapy to succeed. The intelligent eye patch<br />

aims at providing the doctor with objective data about the eye patch wearing schedule. The eye patch<br />

consists of an absorbing cushion and an adhesive strip. The cushion contains a microchip, a contact<br />

sensitive sensor, a timekeeper and a battery.<br />

The microchip and the timekeeper register a signal when the eye patch is in contact with the eye and<br />

a second signal when the contact is broken off. The duration of the signal is saved in the memory of<br />

the microchip. The eye patch stores and processes information that is useful for an appropriate<br />

treatment of the aberration. The cushion also has a data port, so that an external link can be made<br />

between the microchip and a computer.<br />

For healthcare, wellness and fitness applications, strain-sensitive fabrics, introduced in chapter 2.1.3<br />

are often used for the monitoring of body motion and change of shape [47]. The Intellitex Suit has<br />

already been pointed out in a previous chapter. Some more examples can be found below.<br />

For example, University of Pisa constructed an undershirt for continuous cardiopulmonary recording<br />

using woven or knitted strain-sensitive fabrics [56].<br />

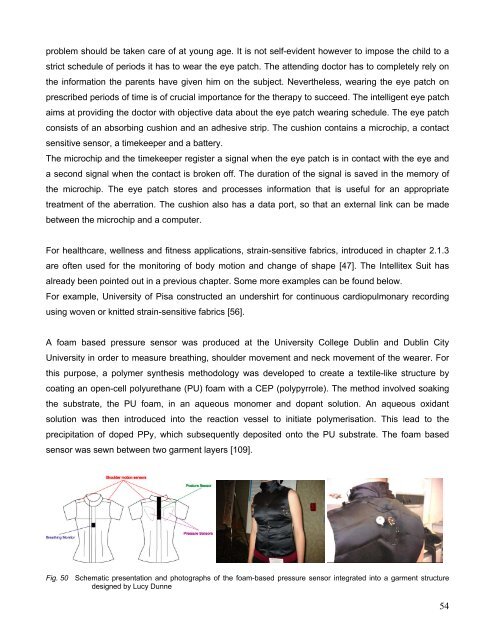

A foam based pressure sensor was produced at the University College Dublin and Dublin City<br />

University in order to measure breathing, shoulder movement and neck movement of the wearer. For<br />

this purpose, a polymer synthesis methodology was developed to create a textile-like structure by<br />

coating an open-cell polyurethane (PU) foam with a CEP (polypyrrole). The method involved soaking<br />

the substrate, the PU foam, in an aqueous monomer and dopant solution. An aqueous oxidant<br />

solution was then introduced into the reaction vessel to initiate polymerisation. This lead to the<br />

precipitation of doped PPy, which subsequently deposited onto the PU substrate. The foam based<br />

sensor was sewn between two garment layers [109].<br />

Fig. 50 Schematic presentation and photographs of the foam-based pressure sensor integrated into a garment structure<br />

designed by Lucy Dunne<br />

54