Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

Clevertex - Grado Zero Espace Srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

on a Jacquard loom before being processed. The remaining, inactive fabric is composed of the floating<br />

fibres on the back of the fabric. A third method uses a two-layer adapted basic-velour fabric that<br />

makes optical fibres as visible as possible. Before being woven, the fibres are chemically processed,<br />

enabling the specific dynamic lighting zones to be created. Further, the researchers modified these<br />

techniques and developed a matrix that enables basic information to be displayed in a static and<br />

dynamic way. A variety of light sources can be used for the structure. The choice mainly depends on<br />

the number of fibres connected to each source and the level of power consumption. The LED<br />

technology in this case is the preferred one, as many effects can be generated on the displays. The<br />

first OFFD was displayed on a jacket. With its function to be seen for security and publicity it has a<br />

great potential to be used for fire fighting and police applications. However, besides for clothing<br />

purposes, it might also be used in car interiors to display information to navigate drivers [152, 153].<br />

Communication between garment and wearer has also been realised by France Telecom with a textile<br />

communication device (OFFD). Glass fibres form a flexible screen which is produced by weaving.<br />

Each plastic fibre-optic thread is illuminated by tiny LEDs that are fixed along the edge of the display<br />

panel and controlled by a microchip. An electronic component is integrated into the material and<br />

controls the LEDS, which illuminate groups of glass fibres independent of one another. These light<br />

and dark patches essentially act as pixels for the display screen. A jacket and backpack have been<br />

produced as prototypes [114, 154].<br />

The US company Luminex designs and manufacturers lighting devices by different technologies.<br />

The so-called UniGlo(R) technology uses optical fibre mounted on a back reflector to create lighting<br />

panels. A computer controlled etching process ensures uniform light distribution.<br />

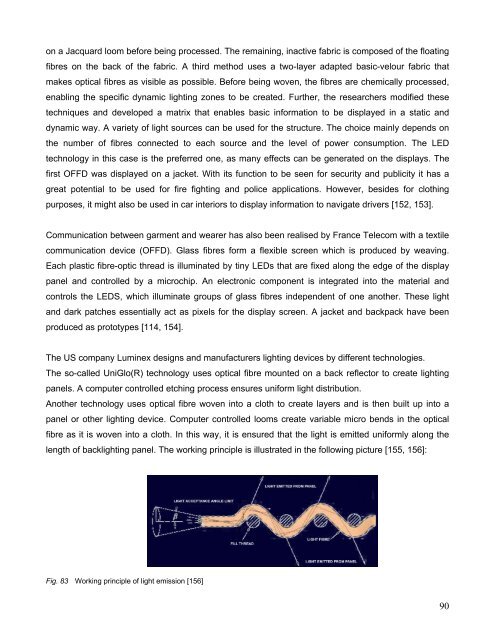

Another technology uses optical fibre woven into a cloth to create layers and is then built up into a<br />

panel or other lighting device. Computer controlled looms create variable micro bends in the optical<br />

fibre as it is woven into a cloth. In this way, it is ensured that the light is emitted uniformly along the<br />

length of backlighting panel. The working principle is illustrated in the following picture [155, 156]:<br />

Fig. 83 Working principle of light emission [156]<br />

90