Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

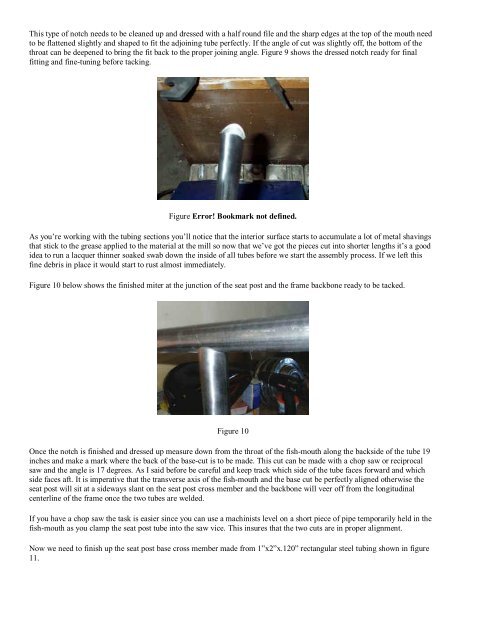

This type of notch needs to be cleaned up and dressed with a half round file and the sharp edges at the top of the mouth need<br />

to be flattened slightly and shaped to fit the adjoining tube perfectly. If the angle of cut was slightly off, the bottom of the<br />

throat can be deepened to bring the fit back to the proper joining angle. Figure 9 shows the dressed notch ready for final<br />

fitting and fine-tuning before tacking.<br />

Figure Error! Bookmark not defined.<br />

As you’re working with the tubing sections you’ll notice that the interior surface starts to accumulate a lot of metal shavings<br />

that stick to the grease applied to the material at the mill so now that we’ve got the pieces cut into shorter lengths it’s a good<br />

idea to run a lacquer thinner soaked swab down the inside of all tubes before we start the assembly process. If we left this<br />

fine debris in place it would start to rust almost immediately.<br />

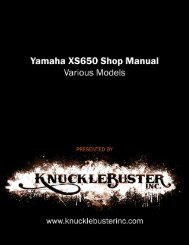

Figure 10 below shows the finished miter at the junction of the seat post and the frame backbone ready to be tacked.<br />

Figure 10<br />

Once the notch is finished and dressed up measure down from the throat of the fish-mouth along the backside of the tube 19<br />

inches and make a mark where the back of the base-cut is to be made. This cut can be made with a chop saw or reciprocal<br />

saw and the angle is 17 degrees. As I said before be careful and keep track which side of the tube faces forward and which<br />

side faces aft. It is imperative that the transverse axis of the fish-mouth and the base cut be perfectly aligned otherwise the<br />

seat post will sit at a sideways slant on the seat post cross member and the backbone will veer off from the longitudinal<br />

centerline of the frame once the two tubes are welded.<br />

If you have a chop saw the task is easier since you can use a machinists level on a short piece of pipe temporarily held in the<br />

fish-mouth as you clamp the seat post tube into the saw vice. This insures that the two cuts are in proper alignment.<br />

Now we need to finish up the seat post base cross member made from 1”x2”x.120” rectangular steel tubing shown in figure<br />

11.