Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

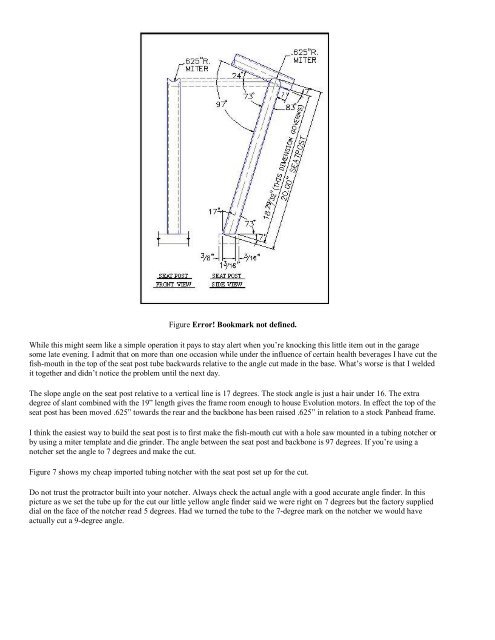

Figure Error! Bookmark not defined.<br />

While this might seem like a simple operation it pays to stay alert when you’re knocking this little item out in the garage<br />

some late evening. I admit that on more than one occasion while under the influence of certain health beverages I have cut the<br />

fish-mouth in the top of the seat post tube backwards relative to the angle cut made in the base. What’s worse is that I welded<br />

it together and didn’t notice the problem until the next day.<br />

The slope angle on the seat post relative to a vertical line is 17 degrees. The stock angle is just a hair under 16. The extra<br />

degree of slant combined with the 19” length gives the frame room enough to house Evolution motors. In effect the top of the<br />

seat post has been moved .625” towards the rear and the backbone has been raised .625” in relation to a stock Panhead frame.<br />

I think the easiest way to build the seat post is to first make the fish-mouth cut with a hole saw mounted in a tubing notcher or<br />

by using a miter template and die grinder. The angle between the seat post and backbone is 97 degrees. If you’re using a<br />

notcher set the angle to 7 degrees and make the cut.<br />

Figure 7 shows my cheap imported tubing notcher with the seat post set up for the cut.<br />

Do not trust the protractor built into your notcher. Always check the actual angle with a good accurate angle finder. In this<br />

picture as we set the tube up for the cut our little yellow angle finder said we were right on 7 degrees but the factory supplied<br />

dial on the face of the notcher read 5 degrees. Had we turned the tube to the 7-degree mark on the notcher we would have<br />

actually cut a 9-degree angle.