Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

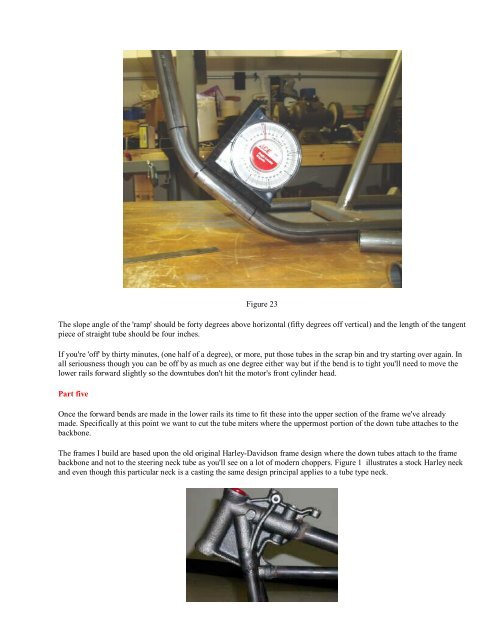

Figure 23<br />

The slope angle of the 'ramp' should be forty degrees above horizontal (fifty degrees off vertical) and the length of the tangent<br />

piece of straight tube should be four inches.<br />

If you're 'off' by thirty minutes, (one half of a degree), or more, put those tubes in the scrap bin and try starting over again. In<br />

all seriousness though you can be off by as much as one degree either way but if the bend is to tight you'll need to move the<br />

lower rails forward slightly so the downtubes don't hit the motor's front cylinder head.<br />

Part five<br />

Once the forward bends are made in the lower rails its time to fit these into the upper section of the frame we've already<br />

made. Specifically at this point we want to cut the tube miters where the uppermost portion of the down tube attaches to the<br />

backbone.<br />

The frames I build are based upon the old original Harley-Davidson frame design where the down tubes attach to the frame<br />

backbone and not to the steering neck tube as you'll see on a lot of modern choppers. Figure 1 illustrates a stock Harley neck<br />

and even though this particular neck is a casting the same design principal applies to a tube type neck.