Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

Old School Chopper Frame Fabrication - Knucklebuster

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

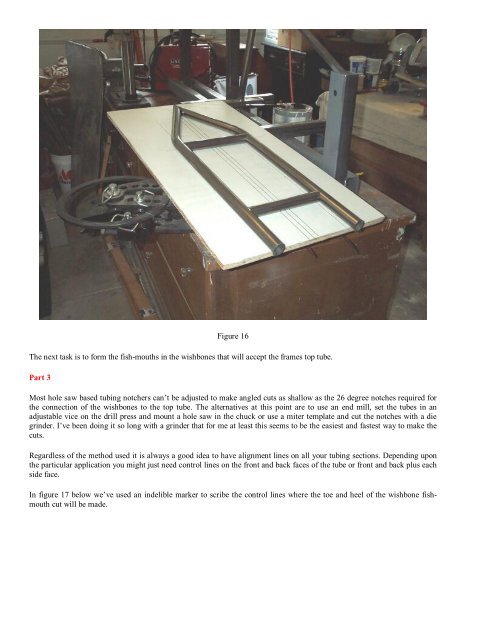

Figure 16<br />

The next task is to form the fish-mouths in the wishbones that will accept the frames top tube.<br />

Part 3<br />

Most hole saw based tubing notchers can’t be adjusted to make angled cuts as shallow as the 26 degree notches required for<br />

the connection of the wishbones to the top tube. The alternatives at this point are to use an end mill, set the tubes in an<br />

adjustable vice on the drill press and mount a hole saw in the chuck or use a miter template and cut the notches with a die<br />

grinder. I’ve been doing it so long with a grinder that for me at least this seems to be the easiest and fastest way to make the<br />

cuts.<br />

Regardless of the method used it is always a good idea to have alignment lines on all your tubing sections. Depending upon<br />

the particular application you might just need control lines on the front and back faces of the tube or front and back plus each<br />

side face.<br />

In figure 17 below we’ve used an indelible marker to scribe the control lines where the toe and heel of the wishbone fishmouth<br />

cut will be made.