Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ROLLING INDUSTRY<br />

ished rolled material but also for <str<strong>on</strong>g>the</str<strong>on</strong>g> slit strip,<br />

development <str<strong>on</strong>g>of</str<strong>on</strong>g> even more precise and rigid<br />

slitting machines is <str<strong>on</strong>g>of</str<strong>on</strong>g> highest importance.<br />

Shearing stresses have a big influence<br />

<strong>on</strong> subsequent workability <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> strip. Single<br />

strips may curl or even jump out <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

stamping die if stresses induced during slit-<br />

ting are too high. Width deviati<strong>on</strong>s could result<br />

in imperfect shapes due to <str<strong>on</strong>g>the</str<strong>on</strong>g> very narrow<br />

trim web at <str<strong>on</strong>g>the</str<strong>on</strong>g> edge <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> strip before<br />

pressing.<br />

With highly accurate adjustment devices,<br />

modern slitting shears provide <str<strong>on</strong>g>the</str<strong>on</strong>g> best chance<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> an exact and repeatable knife shaft adjustment.<br />

It can be seen that <str<strong>on</strong>g>the</str<strong>on</strong>g> slitting shear must<br />

be able to be adjusted as closely as possible<br />

to certain parameters (immersi<strong>on</strong> and cutting<br />

gap) according to <str<strong>on</strong>g>the</str<strong>on</strong>g> material c<strong>on</strong>diti<strong>on</strong>s, this<br />

being essential for thinner strip gauges in particular<br />

Danieli Fröhling accommodates all <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>se through a high standard <str<strong>on</strong>g>of</str<strong>on</strong>g> design and<br />

manufacturing:<br />

• Pre-tensi<strong>on</strong>ed elements giving backlash-<br />

free movement <str<strong>on</strong>g>of</str<strong>on</strong>g> machine parts.<br />

• High accuracy measuring systems to<br />

provide <str<strong>on</strong>g>the</str<strong>on</strong>g> adjustment system with<br />

necessary data. Rigid and solid design to<br />

prevent vibrati<strong>on</strong>.<br />

• Data bases store recipes for different<br />

slitting programmes<br />

• Tool clamping systems to ensure reliable<br />

clamping automatically actuated.<br />

Following <str<strong>on</strong>g>the</str<strong>on</strong>g>se demands, Danieli Fröhling<br />

developed a new generati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> slitting heads.<br />

One <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> main parameters for <str<strong>on</strong>g>the</str<strong>on</strong>g> strip edge<br />

quality is <str<strong>on</strong>g>the</str<strong>on</strong>g> knives’ immersi<strong>on</strong> into <str<strong>on</strong>g>the</str<strong>on</strong>g> material<br />

to be cut. The optimal immersi<strong>on</strong> depends<br />

<strong>on</strong> material grade, c<strong>on</strong>diti<strong>on</strong> and strip<br />

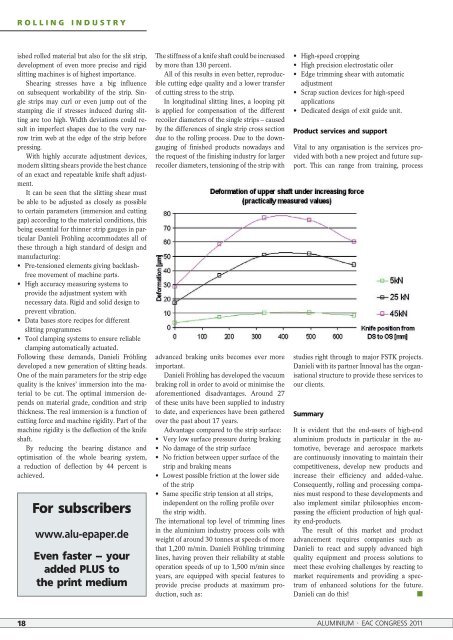

thickness. The real immersi<strong>on</strong> is a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

cutting force and machine rigidity. Part <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

machine rigidity is <str<strong>on</strong>g>the</str<strong>on</strong>g> deflecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> knife<br />

shaft.<br />

By reducing <str<strong>on</strong>g>the</str<strong>on</strong>g> bearing distance and<br />

optimisati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> whole bearing system,<br />

a reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> deflecti<strong>on</strong> by 44 percent is<br />

achieved.<br />

For subscribers<br />

www.alu-epaper.de<br />

Even faster – your<br />

added PLUS to<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> print medium<br />

The stiffness <str<strong>on</strong>g>of</str<strong>on</strong>g> a knife shaft could be increased<br />

by more than 130 percent.<br />

All <str<strong>on</strong>g>of</str<strong>on</strong>g> this results in even better, reproducible<br />

cutting edge quality and a lower transfer<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> cutting stress to <str<strong>on</strong>g>the</str<strong>on</strong>g> strip.<br />

In l<strong>on</strong>gitudinal slitting lines, a looping pit<br />

is applied for compensati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> different<br />

recoiler diameters <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> single strips – caused<br />

by <str<strong>on</strong>g>the</str<strong>on</strong>g> differences <str<strong>on</strong>g>of</str<strong>on</strong>g> single strip cross secti<strong>on</strong><br />

due to <str<strong>on</strong>g>the</str<strong>on</strong>g> rolling process. Due to <str<strong>on</strong>g>the</str<strong>on</strong>g> downgauging<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> finished products nowadays and<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> request <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> finishing industry for larger<br />

recoiler diameters, tensi<strong>on</strong>ing <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> strip with<br />

advanced braking units becomes ever more<br />

important.<br />

Danieli Fröhling has developed <str<strong>on</strong>g>the</str<strong>on</strong>g> vacuum<br />

braking roll in order to avoid or minimise <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

aforementi<strong>on</strong>ed disadvantages. Around 27<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se units have been supplied to industry<br />

to date, and experiences have been ga<str<strong>on</strong>g>the</str<strong>on</strong>g>red<br />

over <str<strong>on</strong>g>the</str<strong>on</strong>g> past about 17 years.<br />

Advantage compared to <str<strong>on</strong>g>the</str<strong>on</strong>g> strip surface:<br />

• Very low surface pressure during braking<br />

• No damage <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> strip surface<br />

• No fricti<strong>on</strong> between upper surface <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

strip and braking means<br />

• Lowest possible fricti<strong>on</strong> at <str<strong>on</strong>g>the</str<strong>on</strong>g> lower side<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> strip<br />

• Same specific strip tensi<strong>on</strong> at all strips,<br />

independent <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> rolling pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile over<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> strip width.<br />

The internati<strong>on</strong>al top level <str<strong>on</strong>g>of</str<strong>on</strong>g> trimming lines<br />

in <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> industry process coils with<br />

weight <str<strong>on</strong>g>of</str<strong>on</strong>g> around 30 t<strong>on</strong>nes at speeds <str<strong>on</strong>g>of</str<strong>on</strong>g> more<br />

that 1,200 m/min. Danieli Fröhling trimming<br />

lines, having proven <str<strong>on</strong>g>the</str<strong>on</strong>g>ir reliability at stable<br />

operati<strong>on</strong> speeds <str<strong>on</strong>g>of</str<strong>on</strong>g> up to 1,500 m/min since<br />

years, are equipped with special features to<br />

provide precise products at maximum pro-<br />

ducti<strong>on</strong>, such as:<br />

• High-speed cropping<br />

• High precisi<strong>on</strong> electrostatic oiler<br />

• Edge trimming shear with automatic<br />

adjustment<br />

• Scrap sucti<strong>on</strong> devices for high-speed<br />

applicati<strong>on</strong>s<br />

• Dedicated design <str<strong>on</strong>g>of</str<strong>on</strong>g> exit guide unit.<br />

Product services and support<br />

Vital to any organisati<strong>on</strong> is <str<strong>on</strong>g>the</str<strong>on</strong>g> services pro-<br />

vided with both a new project and future support.<br />

This can range from training, process<br />

studies right through to major FSTK projects.<br />

Danieli with its partner Innoval has <str<strong>on</strong>g>the</str<strong>on</strong>g> organisati<strong>on</strong>al<br />

structure to provide <str<strong>on</strong>g>the</str<strong>on</strong>g>se services to<br />

our clients.<br />

Summary<br />

It is evident that <str<strong>on</strong>g>the</str<strong>on</strong>g> end-users <str<strong>on</strong>g>of</str<strong>on</strong>g> high-end<br />

<str<strong>on</strong>g>aluminium</str<strong>on</strong>g> products in particular in <str<strong>on</strong>g>the</str<strong>on</strong>g> automotive,<br />

beverage and aerospace markets<br />

are c<strong>on</strong>tinuously innovating to maintain <str<strong>on</strong>g>the</str<strong>on</strong>g>ir<br />

competitiveness, develop new products and<br />

increase <str<strong>on</strong>g>the</str<strong>on</strong>g>ir efficiency and added-value.<br />

C<strong>on</strong>sequently, rolling and processing companies<br />

must resp<strong>on</strong>d to <str<strong>on</strong>g>the</str<strong>on</strong>g>se developments and<br />

also implement similar philosophies encompassing<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> efficient producti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> high quality<br />

end-products.<br />

The result <str<strong>on</strong>g>of</str<strong>on</strong>g> this market and product<br />

advancement requires companies such as<br />

Danieli to react and supply advanced high<br />

quality equipment and process soluti<strong>on</strong>s to<br />

meet <str<strong>on</strong>g>the</str<strong>on</strong>g>se evolving challenges by reacting to<br />

market requirements and providing a spectrum<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> enhanced soluti<strong>on</strong>s for <str<strong>on</strong>g>the</str<strong>on</strong>g> future.<br />

Danieli can do this!<br />

�<br />

18 <strong>ALU</strong>MINIUM · EAC CONGRESS 2011