Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EXTRUSION<br />

Integrated processing <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>aluminium</str<strong>on</strong>g><br />

pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles subsequent to hot extrusi<strong>on</strong><br />

A. Jäger, N. Ben Khalifa, A.E. Tekkaya, Institute <str<strong>on</strong>g>of</str<strong>on</strong>g> Forming Technology<br />

and Lightweight C<strong>on</strong>structi<strong>on</strong>, TU Dortmund University, Dortmund, Germany<br />

Strategies <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmo-mechanical processing<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles subsequent to<br />

hot extrusi<strong>on</strong> were developed and tested.<br />

By using <str<strong>on</strong>g>the</str<strong>on</strong>g> process heat <str<strong>on</strong>g>of</str<strong>on</strong>g> extrusi<strong>on</strong> for<br />

subsequent forming and heat treatment<br />

steps, process chains for <str<strong>on</strong>g>the</str<strong>on</strong>g> producti<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> graded <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles were developed<br />

and realized <strong>on</strong> an experimental<br />

scale. Due to <str<strong>on</strong>g>the</str<strong>on</strong>g> geometric limitati<strong>on</strong>s,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> technology <str<strong>on</strong>g>of</str<strong>on</strong>g> realizing a grading in<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> geometry <str<strong>on</strong>g>of</str<strong>on</strong>g> open and hollow pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles<br />

is different. Therefore, two innovative<br />

c<strong>on</strong>cepts for <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmo-mechanical<br />

processing <str<strong>on</strong>g>of</str<strong>on</strong>g> open and hollow secti<strong>on</strong>s<br />

were developed, allowing electromagnetic<br />

compressi<strong>on</strong> and rolling to become<br />

integrated within <str<strong>on</strong>g>the</str<strong>on</strong>g> process chains. Possible<br />

applicati<strong>on</strong>s are seen in producing<br />

functi<strong>on</strong>ally graded products with locally<br />

adapted properties.<br />

C<strong>on</strong>venti<strong>on</strong>al hot metal extrusi<strong>on</strong> is used to<br />

produce straight, semi-finished products in<br />

mass producti<strong>on</strong> (Laue and Stenger, 1976) with<br />

a c<strong>on</strong>stant cross secti<strong>on</strong> over <str<strong>on</strong>g>the</str<strong>on</strong>g> length and<br />

homogeneous mechanical and micro-structural<br />

properties (Hall and Mudawar, 1996).<br />

Aluminium secti<strong>on</strong>s are frequently used as<br />

c<strong>on</strong>structi<strong>on</strong> elements. Generally, <str<strong>on</strong>g>the</str<strong>on</strong>g> loading<br />

c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> structure elements in technical<br />

c<strong>on</strong>structi<strong>on</strong>s differ locally. The c<strong>on</strong>stant cross<br />

Fig. 2: C<strong>on</strong>cept <str<strong>on</strong>g>of</str<strong>on</strong>g> extrusi<strong>on</strong> and subsequent forming by rollers (schematic)<br />

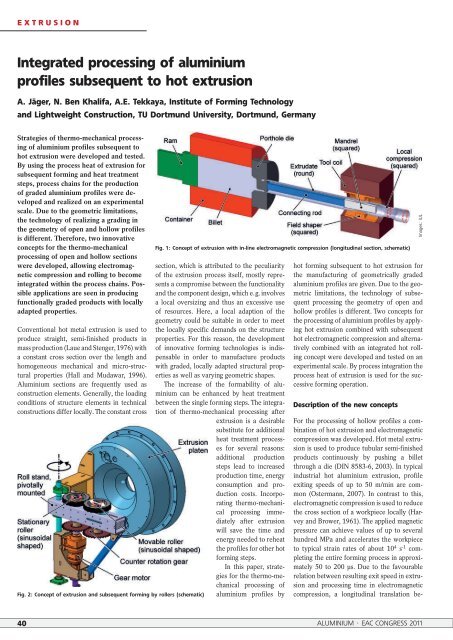

Fig. 1: C<strong>on</strong>cept <str<strong>on</strong>g>of</str<strong>on</strong>g> extrusi<strong>on</strong> with in-line electromagnetic compressi<strong>on</strong> (l<strong>on</strong>gitudinal secti<strong>on</strong>, schematic)<br />

secti<strong>on</strong>, which is attributed to <str<strong>on</strong>g>the</str<strong>on</strong>g> peculiarity<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> extrusi<strong>on</strong> process itself, mostly represents<br />

a compromise between <str<strong>on</strong>g>the</str<strong>on</strong>g> functi<strong>on</strong>ality<br />

and <str<strong>on</strong>g>the</str<strong>on</strong>g> comp<strong>on</strong>ent design, which e. g. involves<br />

a local oversizing and thus an excessive use<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> resources. Here, a local adapti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

geometry could be suitable in order to meet<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> locally specific demands <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> structure<br />

properties. For this reas<strong>on</strong>, <str<strong>on</strong>g>the</str<strong>on</strong>g> development<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> innovative forming technologies is indispensable<br />

in order to manufacture products<br />

with graded, locally adapted structural properties<br />

as well as varying geometric shapes.<br />

The increase <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> formability <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>aluminium</str<strong>on</strong>g><br />

can be enhanced by heat treatment<br />

between <str<strong>on</strong>g>the</str<strong>on</strong>g> single forming steps. The integrati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmo-mechanical processing after<br />

extrusi<strong>on</strong> is a desirable<br />

substitute for additi<strong>on</strong>al<br />

heat treatment processes<br />

for several reas<strong>on</strong>s:<br />

additi<strong>on</strong>al producti<strong>on</strong><br />

steps lead to increased<br />

producti<strong>on</strong> time, energy<br />

c<strong>on</strong>sumpti<strong>on</strong> and producti<strong>on</strong><br />

costs. Incorporating<str<strong>on</strong>g>the</str<strong>on</strong>g>rmo-mechanical<br />

processing immediately<br />

after extrusi<strong>on</strong><br />

will save <str<strong>on</strong>g>the</str<strong>on</strong>g> time and<br />

energy needed to reheat<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles for o<str<strong>on</strong>g>the</str<strong>on</strong>g>r hot<br />

forming steps.<br />

In this paper, strategies<br />

for <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmo-mechanical<br />

processing <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>aluminium</str<strong>on</strong>g> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles by<br />

hot forming subsequent to hot extrusi<strong>on</strong> for<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> manufacturing <str<strong>on</strong>g>of</str<strong>on</strong>g> geometrically graded<br />

<str<strong>on</strong>g>aluminium</str<strong>on</strong>g> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles are given. Due to <str<strong>on</strong>g>the</str<strong>on</strong>g> geometric<br />

limitati<strong>on</strong>s, <str<strong>on</strong>g>the</str<strong>on</strong>g> technology <str<strong>on</strong>g>of</str<strong>on</strong>g> subsequent<br />

processing <str<strong>on</strong>g>the</str<strong>on</strong>g> geometry <str<strong>on</strong>g>of</str<strong>on</strong>g> open and<br />

hollow pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles is different. Two c<strong>on</strong>cepts for<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> processing <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles by applying<br />

hot extrusi<strong>on</strong> combined with subsequent<br />

hot electromagnetic compressi<strong>on</strong> and alternatively<br />

combined with an integrated hot rolling<br />

c<strong>on</strong>cept were developed and tested <strong>on</strong> an<br />

experimental scale. By process integrati<strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

process heat <str<strong>on</strong>g>of</str<strong>on</strong>g> extrusi<strong>on</strong> is used for <str<strong>on</strong>g>the</str<strong>on</strong>g> successive<br />

forming operati<strong>on</strong>.<br />

Descripti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> new c<strong>on</strong>cepts<br />

For <str<strong>on</strong>g>the</str<strong>on</strong>g> processing <str<strong>on</strong>g>of</str<strong>on</strong>g> hollow pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles a combinati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> hot extrusi<strong>on</strong> and electromagnetic<br />

compressi<strong>on</strong> was developed. Hot metal extrusi<strong>on</strong><br />

is used to produce tubular semi-finished<br />

products c<strong>on</strong>tinuously by pushing a billet<br />

through a die (DIN 8583-6, 2003). In typical<br />

industrial hot <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> extrusi<strong>on</strong>, pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile<br />

exiting speeds <str<strong>on</strong>g>of</str<strong>on</strong>g> up to 50 m/min are comm<strong>on</strong><br />

(Ostermann, 2007). In c<strong>on</strong>trast to this,<br />

electromagnetic compressi<strong>on</strong> is used to reduce<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> cross secti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a workpiece locally (Harvey<br />

and Brower, 1961). The applied magnetic<br />

pressure can achieve values <str<strong>on</strong>g>of</str<strong>on</strong>g> up to several<br />

hundred MPa and accelerates <str<strong>on</strong>g>the</str<strong>on</strong>g> workpiece<br />

to typical strain rates <str<strong>on</strong>g>of</str<strong>on</strong>g> about 10 4 s -1 completing<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> entire forming process in approximately<br />

50 to 200 μs. Due to <str<strong>on</strong>g>the</str<strong>on</strong>g> favourable<br />

relati<strong>on</strong> between resulting exit speed in extrusi<strong>on</strong><br />

and processing time in electromagnetic<br />

compressi<strong>on</strong>, a l<strong>on</strong>gitudinal translati<strong>on</strong> be-<br />

40 <strong>ALU</strong>MINIUM · EAC CONGRESS 2011<br />

Images: IUL