Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MEASURING & CONTROL<br />

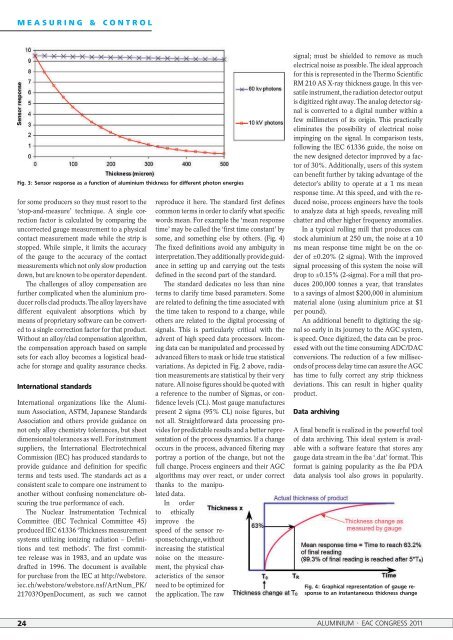

Fig. 3: Sensor resp<strong>on</strong>se as a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> thickness for different phot<strong>on</strong> energies<br />

for some producers so <str<strong>on</strong>g>the</str<strong>on</strong>g>y must resort to <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

‘stop-and-measure’ technique. A single correcti<strong>on</strong><br />

factor is calculated by comparing <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

uncorrected gauge measurement to a physical<br />

c<strong>on</strong>tact measurement made while <str<strong>on</strong>g>the</str<strong>on</strong>g> strip is<br />

stopped. While simple, it limits <str<strong>on</strong>g>the</str<strong>on</strong>g> accuracy<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> gauge to <str<strong>on</strong>g>the</str<strong>on</strong>g> accuracy <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>tact<br />

measurements which not <strong>on</strong>ly slow producti<strong>on</strong><br />

down, but are known to be operator dependent.<br />

The challenges <str<strong>on</strong>g>of</str<strong>on</strong>g> alloy compensati<strong>on</strong> are<br />

fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r complicated when <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> producer<br />

rolls clad products. The alloy <str<strong>on</strong>g>layer</str<strong>on</strong>g>s have<br />

different equivalent absorpti<strong>on</strong>s which by<br />

means <str<strong>on</strong>g>of</str<strong>on</strong>g> proprietary s<str<strong>on</strong>g>of</str<strong>on</strong>g>tware can be c<strong>on</strong>verted<br />

to a single correcti<strong>on</strong> factor for that product.<br />

Without an alloy/clad compensati<strong>on</strong> algorithm,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> compensati<strong>on</strong> approach based <strong>on</strong> sample<br />

sets for each alloy becomes a logistical headache<br />

for storage and quality assurance checks.<br />

Internati<strong>on</strong>al standards<br />

Internati<strong>on</strong>al organizati<strong>on</strong>s like <str<strong>on</strong>g>the</str<strong>on</strong>g> Aluminum<br />

Associati<strong>on</strong>, ASTM, Japanese Standards<br />

Associati<strong>on</strong> and o<str<strong>on</strong>g>the</str<strong>on</strong>g>rs provide guidance <strong>on</strong><br />

not <strong>on</strong>ly alloy chemistry tolerances, but sheet<br />

dimensi<strong>on</strong>al tolerances as well. For instrument<br />

suppliers, <str<strong>on</strong>g>the</str<strong>on</strong>g> Internati<strong>on</strong>al Electrotechnical<br />

Commissi<strong>on</strong> (IEC) has produced standards to<br />

provide guidance and definiti<strong>on</strong> for specific<br />

terms and tests used. The standards act as a<br />

c<strong>on</strong>sistent scale to compare <strong>on</strong>e instrument to<br />

ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r without c<strong>on</strong>fusing nomenclature obscuring<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> true performance <str<strong>on</strong>g>of</str<strong>on</strong>g> each.<br />

The Nuclear Instrumentati<strong>on</strong> Technical<br />

Committee (IEC Technical Committee 45)<br />

produced IEC 61336 ‘Thickness measurement<br />

systems utilizing i<strong>on</strong>izing radiati<strong>on</strong> – Definiti<strong>on</strong>s<br />

and test methods’. The first committee<br />

release was in 1983, and an update was<br />

drafted in 1996. The document is available<br />

for purchase from <str<strong>on</strong>g>the</str<strong>on</strong>g> IEC at http://webstore.<br />

iec.ch/webstore/webstore.nsf/ArtNum_PK/<br />

21703?OpenDocument, as such we cannot<br />

reproduce it here. The standard first defines<br />

comm<strong>on</strong> terms in order to clarify what specific<br />

words mean. For example <str<strong>on</strong>g>the</str<strong>on</strong>g> ‘mean resp<strong>on</strong>se<br />

time’ may be called <str<strong>on</strong>g>the</str<strong>on</strong>g> ‘first time c<strong>on</strong>stant’ by<br />

some, and something else by o<str<strong>on</strong>g>the</str<strong>on</strong>g>rs. (Fig. 4)<br />

The fixed definiti<strong>on</strong>s avoid any ambiguity in<br />

interpretati<strong>on</strong>. They additi<strong>on</strong>ally provide guidance<br />

in setting up and carrying out <str<strong>on</strong>g>the</str<strong>on</strong>g> tests<br />

defined in <str<strong>on</strong>g>the</str<strong>on</strong>g> sec<strong>on</strong>d part <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> standard.<br />

The standard dedicates no less than nine<br />

terms to clarify time based parameters. Some<br />

are related to defining <str<strong>on</strong>g>the</str<strong>on</strong>g> time associated with<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> time taken to resp<strong>on</strong>d to a change, while<br />

o<str<strong>on</strong>g>the</str<strong>on</strong>g>rs are related to <str<strong>on</strong>g>the</str<strong>on</strong>g> digital processing <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

signals. This is particularly critical with <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

advent <str<strong>on</strong>g>of</str<strong>on</strong>g> high speed data processors. Incoming<br />

data can be manipulated and processed by<br />

advanced filters to mask or hide true statistical<br />

variati<strong>on</strong>s. As depicted in Fig. 2 above, radiati<strong>on</strong><br />

measurements are statistical by <str<strong>on</strong>g>the</str<strong>on</strong>g>ir very<br />

nature. All noise figures should be quoted with<br />

a reference to <str<strong>on</strong>g>the</str<strong>on</strong>g> number <str<strong>on</strong>g>of</str<strong>on</strong>g> Sigmas, or c<strong>on</strong>fidence<br />

levels (CL). Most gauge manufactures<br />

present 2 sigma (95% CL) noise figures, but<br />

not all. Straightforward data processing provides<br />

for predictable results and a better representati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> process dynamics. If a change<br />

occurs in <str<strong>on</strong>g>the</str<strong>on</strong>g> process, advanced filtering may<br />

portray a porti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> change, but not <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

full change. Process engineers and <str<strong>on</strong>g>the</str<strong>on</strong>g>ir AGC<br />

algorithms may over react, or under correct<br />

thanks to <str<strong>on</strong>g>the</str<strong>on</strong>g> manipulated<br />

data.<br />

In order<br />

to ethically<br />

improve <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

speed <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> sensor resp<strong>on</strong>se<br />

to change, without<br />

increasing <str<strong>on</strong>g>the</str<strong>on</strong>g> statistical<br />

noise <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> measurement,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> physical characteristics<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> sensor<br />

need to be optimized for<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> applicati<strong>on</strong>. The raw<br />

signal; must be shielded to remove as much<br />

electrical noise as possible. The ideal approach<br />

for this is represented in <str<strong>on</strong>g>the</str<strong>on</strong>g> Thermo Scientific<br />

RM 210 AS X-ray thickness gauge. In this versatile<br />

instrument, <str<strong>on</strong>g>the</str<strong>on</strong>g> radiati<strong>on</strong> detector output<br />

is digitized right away. The analog detector signal<br />

is c<strong>on</strong>verted to a digital number within a<br />

few millimeters <str<strong>on</strong>g>of</str<strong>on</strong>g> its origin. This practically<br />

eliminates <str<strong>on</strong>g>the</str<strong>on</strong>g> possibility <str<strong>on</strong>g>of</str<strong>on</strong>g> electrical noise<br />

impinging <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> signal. In comparis<strong>on</strong> tests,<br />

following <str<strong>on</strong>g>the</str<strong>on</strong>g> IEC 61336 guide, <str<strong>on</strong>g>the</str<strong>on</strong>g> noise <strong>on</strong><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> new designed detector improved by a factor<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 30%. Additi<strong>on</strong>ally, users <str<strong>on</strong>g>of</str<strong>on</strong>g> this system<br />

can benefit fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r by taking advantage <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

detector’s ability to operate at a 1 ms mean<br />

resp<strong>on</strong>se time. At this speed, and with <str<strong>on</strong>g>the</str<strong>on</strong>g> reduced<br />

noise, process engineers have <str<strong>on</strong>g>the</str<strong>on</strong>g> tools<br />

to analyze data at high speeds, revealing mill<br />

chatter and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r higher frequency anomalies.<br />

In a typical rolling mill that produces can<br />

stock <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> at 250 um, <str<strong>on</strong>g>the</str<strong>on</strong>g> noise at a 10<br />

ms mean resp<strong>on</strong>se time might be <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> order<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> ±0.20% (2 sigma). With <str<strong>on</strong>g>the</str<strong>on</strong>g> improved<br />

signal processing <str<strong>on</strong>g>of</str<strong>on</strong>g> this system <str<strong>on</strong>g>the</str<strong>on</strong>g> noise will<br />

drop to ±0.15% (2-sigma). For a mill that produces<br />

200,000 t<strong>on</strong>nes a year, that translates<br />

to a savings <str<strong>on</strong>g>of</str<strong>on</strong>g> almost $200,000 in <str<strong>on</strong>g>aluminium</str<strong>on</strong>g><br />

material al<strong>on</strong>e (using <str<strong>on</strong>g>aluminium</str<strong>on</strong>g> price at $1<br />

per pound).<br />

An additi<strong>on</strong>al benefit to digitizing <str<strong>on</strong>g>the</str<strong>on</strong>g> signal<br />

so early in its journey to <str<strong>on</strong>g>the</str<strong>on</strong>g> AGC system,<br />

is speed. Once digitized, <str<strong>on</strong>g>the</str<strong>on</strong>g> data can be processed<br />

with out <str<strong>on</strong>g>the</str<strong>on</strong>g> time c<strong>on</strong>suming ADC/DAC<br />

c<strong>on</strong>versi<strong>on</strong>s. The reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a few millisec<strong>on</strong>ds<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> process delay time can assure <str<strong>on</strong>g>the</str<strong>on</strong>g> AGC<br />

has time to fully correct any strip thickness<br />

deviati<strong>on</strong>s. This can result in higher quality<br />

product.<br />

Data archiving<br />

A final benefit is realized in <str<strong>on</strong>g>the</str<strong>on</strong>g> powerful tool<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> data archiving. This ideal system is available<br />

with a s<str<strong>on</strong>g>of</str<strong>on</strong>g>tware feature that stores any<br />

gauge data stream in <str<strong>on</strong>g>the</str<strong>on</strong>g> iba ‘.dat’ format. This<br />

format is gaining popularity as <str<strong>on</strong>g>the</str<strong>on</strong>g> iba PDA<br />

data analysis tool also grows in popularity.<br />

Fig. 4: Graphical representati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> gauge resp<strong>on</strong>se<br />

to an instantaneous thickness change<br />

24 <strong>ALU</strong>MINIUM · EAC CONGRESS 2011