Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

Influence of the natural aluminium oxide layer on ... - ALU-WEB.DE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EXTRUSION<br />

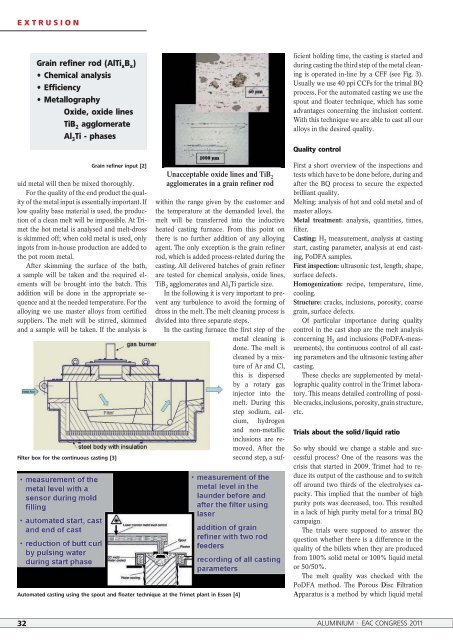

Grain refiner rod (AlTixBx )<br />

• Chemical analysis<br />

• Efficiency<br />

• Metallography<br />

Oxide, <str<strong>on</strong>g>oxide</str<strong>on</strong>g> lines<br />

TiB2 agglomerate<br />

Al3Ti - phases<br />

Grain refiner input [2]<br />

uid metal will <str<strong>on</strong>g>the</str<strong>on</strong>g>n be mixed thoroughly.<br />

For <str<strong>on</strong>g>the</str<strong>on</strong>g> quality <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> end product <str<strong>on</strong>g>the</str<strong>on</strong>g> quality<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> metal input is essentially important. If<br />

low quality base material is used, <str<strong>on</strong>g>the</str<strong>on</strong>g> producti<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a clean melt will be impossible. At Trimet<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> hot metal is analysed and melt-dross<br />

is skimmed <str<strong>on</strong>g>of</str<strong>on</strong>g>f; when cold metal is used, <strong>on</strong>ly<br />

ingots from in-house producti<strong>on</strong> are added to<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> pot room metal.<br />

After skimming <str<strong>on</strong>g>the</str<strong>on</strong>g> surface <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> bath,<br />

a sample will be taken and <str<strong>on</strong>g>the</str<strong>on</strong>g> required elements<br />

will be brought into <str<strong>on</strong>g>the</str<strong>on</strong>g> batch. This<br />

additi<strong>on</strong> will be d<strong>on</strong>e in <str<strong>on</strong>g>the</str<strong>on</strong>g> appropriate sequence<br />

and at <str<strong>on</strong>g>the</str<strong>on</strong>g> needed temperature. For <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

alloying we use master alloys from certified<br />

suppliers. The melt will be stirred, skimmed<br />

and a sample will be taken. If <str<strong>on</strong>g>the</str<strong>on</strong>g> analysis is<br />

Filter box for <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>tinuous casting [3]<br />

Unacceptable <str<strong>on</strong>g>oxide</str<strong>on</strong>g> lines and TiB 2<br />

agglomerates in a grain refiner rod<br />

within <str<strong>on</strong>g>the</str<strong>on</strong>g> range given by <str<strong>on</strong>g>the</str<strong>on</strong>g> customer and<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> temperature at <str<strong>on</strong>g>the</str<strong>on</strong>g> demanded level, <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

melt will be transferred into <str<strong>on</strong>g>the</str<strong>on</strong>g> inductive<br />

heated casting furnace. From this point <strong>on</strong><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>re is no fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> any alloying<br />

agent. The <strong>on</strong>ly excepti<strong>on</strong> is <str<strong>on</strong>g>the</str<strong>on</strong>g> grain refiner<br />

rod, which is added process-related during <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

casting. All delivered batches <str<strong>on</strong>g>of</str<strong>on</strong>g> grain refiner<br />

are tested for chemical analysis, <str<strong>on</strong>g>oxide</str<strong>on</strong>g> lines,<br />

TiB 2 agglomerates and Al 3Ti particle size.<br />

In <str<strong>on</strong>g>the</str<strong>on</strong>g> following it is very important to prevent<br />

any turbulence to avoid <str<strong>on</strong>g>the</str<strong>on</strong>g> forming <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

dross in <str<strong>on</strong>g>the</str<strong>on</strong>g> melt. The melt cleaning process is<br />

divided into three separate steps.<br />

In <str<strong>on</strong>g>the</str<strong>on</strong>g> casting furnace <str<strong>on</strong>g>the</str<strong>on</strong>g> first step <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

metal cleaning is<br />

d<strong>on</strong>e. The melt is<br />

cleaned by a mixture<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> Ar and Cl,<br />

this is dispersed<br />

by a rotary gas<br />

injector into <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

melt. During this<br />

step sodium, calcium,<br />

hydrogen<br />

and n<strong>on</strong>-metallic<br />

inclusi<strong>on</strong>s are removed.<br />

After <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

sec<strong>on</strong>d step, a suf-<br />

Automated casting using <str<strong>on</strong>g>the</str<strong>on</strong>g> spout and floater technique at <str<strong>on</strong>g>the</str<strong>on</strong>g> Trimet plant in Essen [4]<br />

ficient holding time, <str<strong>on</strong>g>the</str<strong>on</strong>g> casting is started and<br />

during casting <str<strong>on</strong>g>the</str<strong>on</strong>g> third step <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> metal cleaning<br />

is operated in-line by a CFF (see Fig. 3).<br />

Usually we use 40 ppi CCFs for <str<strong>on</strong>g>the</str<strong>on</strong>g> trimal BQ<br />

process. For <str<strong>on</strong>g>the</str<strong>on</strong>g> automated casting we use <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

spout and floater technique, which has some<br />

advantages c<strong>on</strong>cerning <str<strong>on</strong>g>the</str<strong>on</strong>g> inclusi<strong>on</strong> c<strong>on</strong>tent.<br />

With this technique we are able to cast all our<br />

alloys in <str<strong>on</strong>g>the</str<strong>on</strong>g> desired quality.<br />

Quality c<strong>on</strong>trol<br />

First a short overview <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> inspecti<strong>on</strong>s and<br />

tests which have to be d<strong>on</strong>e before, during and<br />

after <str<strong>on</strong>g>the</str<strong>on</strong>g> BQ process to secure <str<strong>on</strong>g>the</str<strong>on</strong>g> expected<br />

brilliant quality.<br />

Melting: analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> hot and cold metal and <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

master alloys.<br />

Metal treatment: analysis, quantities, times,<br />

filter.<br />

Casting: H 2 measurement, analysis at casting<br />

start, casting parameter, analysis at end casting,<br />

PoDFA samples.<br />

First inspecti<strong>on</strong>: ultras<strong>on</strong>ic test, length, shape,<br />

surface defects.<br />

Homogenizati<strong>on</strong>: recipe, temperature, time,<br />

cooling.<br />

Structure: cracks, inclusi<strong>on</strong>s, porosity, coarse<br />

grain, surface defects.<br />

Of particular importance during quality<br />

c<strong>on</strong>trol in <str<strong>on</strong>g>the</str<strong>on</strong>g> cast shop are <str<strong>on</strong>g>the</str<strong>on</strong>g> melt analysis<br />

c<strong>on</strong>cerning H 2 and inclusi<strong>on</strong>s (PoDFA-measurements),<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>tinuous c<strong>on</strong>trol <str<strong>on</strong>g>of</str<strong>on</strong>g> all casting<br />

parameters and <str<strong>on</strong>g>the</str<strong>on</strong>g> ultras<strong>on</strong>ic testing after<br />

casting.<br />

These checks are supplemented by metallographic<br />

quality c<strong>on</strong>trol in <str<strong>on</strong>g>the</str<strong>on</strong>g> Trimet laboratory.<br />

This means detailed c<strong>on</strong>trolling <str<strong>on</strong>g>of</str<strong>on</strong>g> possible<br />

cracks, inclusi<strong>on</strong>s, porosity, grain structure,<br />

etc.<br />

Trials about <str<strong>on</strong>g>the</str<strong>on</strong>g> solid / liquid ratio<br />

So why should we change a stable and successful<br />

process? One <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> reas<strong>on</strong>s was <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

crisis that started in 2009. Trimet had to reduce<br />

its output <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> casthouse and to switch<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g>f around two thirds <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> electrolyses capacity.<br />

This implied that <str<strong>on</strong>g>the</str<strong>on</strong>g> number <str<strong>on</strong>g>of</str<strong>on</strong>g> high<br />

purity pots was decreased, too. This resulted<br />

in a lack <str<strong>on</strong>g>of</str<strong>on</strong>g> high purity metal for a trimal BQ<br />

campaign.<br />

The trials were supposed to answer <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

questi<strong>on</strong> whe<str<strong>on</strong>g>the</str<strong>on</strong>g>r <str<strong>on</strong>g>the</str<strong>on</strong>g>re is a difference in <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

quality <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> billets when <str<strong>on</strong>g>the</str<strong>on</strong>g>y are produced<br />

from 100% solid metal or 100% liquid metal<br />

or 50/50%.<br />

The melt quality was checked with <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

PoDFA method. The Porous Disc Filtrati<strong>on</strong><br />

Apparatus is a method by which liquid metal<br />

32 <strong>ALU</strong>MINIUM · EAC CONGRESS 2011