In Fonderia 6 2023

Sesto numero del 2023 di In Fonderia

Sesto numero del 2023 di In Fonderia

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECNICO<br />

• System monitored by specialised technicians.<br />

• Environmental measurements of dust levels<br />

taken before and after system installation.<br />

• Periodic reports on system status and results<br />

(dust level in the area, amount of dust collected<br />

by filters, etc.).<br />

• Possibility of online monitoring of operating<br />

parameters and performance in real time.<br />

ficata, rumorosità, efficienza dei filtri, etc) fino<br />

ad arrivare alla gestione globale integrata del<br />

sistema che, grazie all’installazione di sensori<br />

ambientali permanenti, permette di gestire il<br />

set point di funzionamento di ogni unità di filtrazione<br />

in base all’andamento del livello istantaneo<br />

di polverosità rilevato nei vari punti dello<br />

stabilimento. Il sistema si adegua in continuo<br />

per mantenere il livello di pulizia desiderato e<br />

ottimizzare i consumi elettrici e la durata dei filtri,<br />

oltre a monitorare lo stato di funzionamento<br />

e agire in modo intelligente con i predittivi guasti<br />

e comunicando eventuali situazioni potenzialmente<br />

critiche. <br />

Luigi Dotti<br />

Zehnder Group Italia Srl<br />

Questo articolo è stato inviato dall’autore dietro<br />

richiesta della redazione di “<strong>In</strong> <strong>Fonderia</strong>” e<br />

selezionato fra le presentazioni del 36° Congresso<br />

Tecnico di <strong>Fonderia</strong>, organizzato da Assofond<br />

il 17, 18 e 21, 22 novembre 2022.<br />

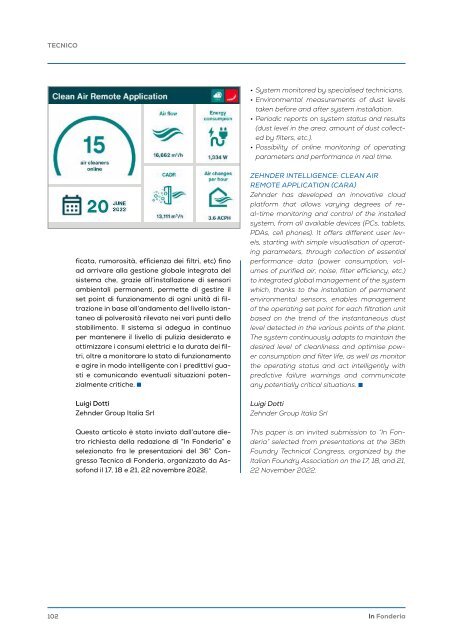

ZEHNDER INTELLIGENCE: CLEAN AIR<br />

REMOTE APPLICATION (CARA)<br />

Zehnder has developed an innovative cloud<br />

platform that allows varying degrees of real-time<br />

monitoring and control of the installed<br />

system, from all available devices (PCs, tablets,<br />

PDAs, cell phones). It offers different user levels,<br />

starting with simple visualisation of operating<br />

parameters, through collection of essential<br />

performance data (power consumption, volumes<br />

of purified air, noise, filter efficiency, etc.)<br />

to integrated global management of the system<br />

which, thanks to the installation of permanent<br />

environmental sensors, enables management<br />

of the operating set point for each filtration unit<br />

based on the trend of the instantaneous dust<br />

level detected in the various points of the plant.<br />

The system continuously adapts to maintain the<br />

desired level of cleanliness and optimise power<br />

consumption and filter life, as well as monitor<br />

the operating status and act intelligently with<br />

predictive failure warnings and communicate<br />

any potentially critical situations. <br />

Luigi Dotti<br />

Zehnder Group Italia Srl<br />

This paper is an invited submission to “<strong>In</strong> <strong>Fonderia</strong>”<br />

selected from presentations at the 36th<br />

Foundry Technical Congress, organized by the<br />

Italian Foundry Association on the 17, 18, and 21,<br />

22 November 2022.<br />

102<br />

<strong>In</strong> <strong>Fonderia</strong>