The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1893] THE LOCOMOTIVE, 139<br />

be made of tlie very best round iron, one inch in diameter, and of single lengths. <strong>The</strong><br />

ends should be upset until sufficient stock is ol>tained to form the jaw and foot for<br />

attachment to the shell. This involves somewhat more labor than making them with<br />

welds, but a sound brace is insured, which is not the ca.se with a welded brace. It is no<br />

unusual thing to find braces just welded up, and by good workmen too, which may be<br />

snapped in two like pipe-stems by striking them a sharp blow across the corner of the<br />

anvil. This is the usual way of testing such work in some shops.<br />

Fig. 13 shows a very common method of bracing the heads of tubular boilers. Two<br />

pieces of L iron are riveted horizontally across the head of the boiler above the tubes.<br />

<strong>The</strong> braces are then attached by pins passing through, and are held between the L irons<br />

as shown. Fig. 14 is an enlarged view of this brace. It differs from Fig. 12 only in the<br />

form of the head, which is single instead of double. This makes a fairly good form of<br />

brace if it is properly constructed, but, as a general rule, it is not. If the braces were<br />

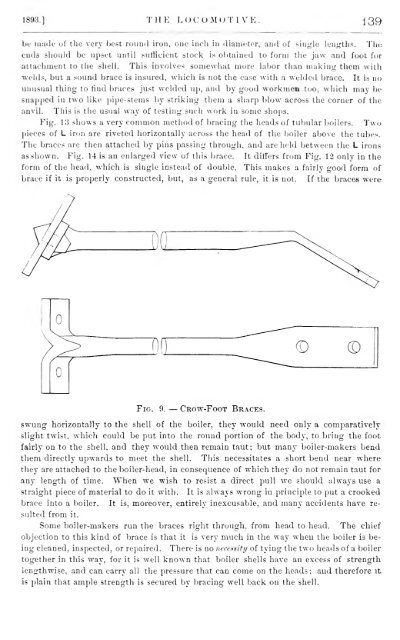

Fig. 9. — Crow-Foot Braces.<br />

swTing horizontally to the shell of the boiler, they would need only a comparatively<br />

slight twist, which could be put into the round portion of the body, to bring the foot<br />

fairly on to the shell, and they would then remain taut; but many boiler-makers bend<br />

them directly upwards to meet the shell. This necessitates a short bend near where<br />

they are attached to the boiler-head, in consequence of which they do not remain taut for<br />

any length of time. When we wish to resist a direct pull we should always use a<br />

straight piece of material to do it with. It is always wrong in principle to put a crooked<br />

brace into a boiler. It is, moreover, entirely inexcusable, and many accidents have re-<br />

sulted from it.<br />

Some boiler-makers run the braces right through, from head to head. <strong>The</strong> chief<br />

objection to this kind of brace is that it is very much in the way when the boiler is be-<br />

ing cleaned, inspected, or repaired. <strong>The</strong>re is no necemty of tying the two heads of a boiler<br />

together in this way, for it is well known that boiler shells have an excess of strength<br />

lengthwise, and can carry all the pressure that can come on the heads ; and therefore it<br />

is plain that ample strength is secured by bracing well back on the shell.<br />

(D