The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

162 THE LOCOMOTIVE. [November,<br />

that have been turned to too short a radius. Careless flanging is apt to start small cracks<br />

through the skin of the iron, and these frequently extend inward and eventually become<br />

dangerous. Incipient cracks on the inside of a boiler sometimes develop into deep<br />

grooves, the slight yielding of the shell, under varying pressure, opeuing up the<br />

interior of the metal to the corrosive action of the water. Defects of this kind usually<br />

occur along the edge of lai^-joints, or near stay-bolts, where the shell is partially stiffened,<br />

and the buckling action of the plates more pronounced.<br />

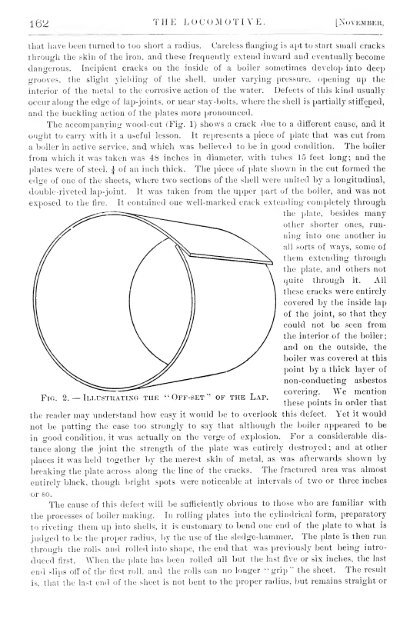

<strong>The</strong> accompanying wood-cut (Fig. 1) shows a crack due to a different cause, and it<br />

ought to carry with it a useful lesson. It represents a piece of plate that was cut from<br />

a boiler in active service, and which was believed to be in good condition. <strong>The</strong> boiler<br />

from which it was taken was 48 inches in diameter, with tubes 15 feet long; and the<br />

plates were of steel, ^ of an inch thick. <strong>The</strong> piece of plate shown in the cut formed the<br />

edge of one of the sheets, where two sections of the shell were united by a longitudinal,<br />

double -riveted lap-joint. It was taken from the upper part of the boiler, and was not<br />

exposed to the fire. It contained one well-marked crack extending completely through<br />

the plate, besides many<br />

Iliastkating the "Off-set" of the Lap.<br />

other shorter ones, run-<br />

ning into one another in<br />

all sorts of ways, some of<br />

them extending through<br />

the plate, and others not<br />

quite through it. All<br />

these cracks were entirely<br />

covered by the inside lap<br />

of the joint, so that they<br />

could not be .seen from<br />

the interior of the boiler;<br />

and on the outside, the<br />

boiler was covered at this<br />

point by a thick layer of<br />

non-conducting asbestos<br />

covering. We mention<br />

these points in order that<br />

the reader may understand how easy it would be to overlook this defect. Yet it would<br />

not be putting the case too strongly to say that although the boiler appeared to be<br />

in good condition, it was actually on the verge of explosion. For a considerable dis-<br />

tance along the joint the strength of the plate was entirely destroyed; and at other<br />

places it was held together by the merest skin of metal, as was afterwards shown by<br />

breaking the plate across along the line of the cracks. <strong>The</strong> fractured area was almost<br />

entirely black, though bright spots were noticeable at intervals of two or three inches<br />

•or so.<br />

<strong>The</strong> cause of this defect will be sufficiently obvious to those who are familiar with<br />

the processes of boiler making. In rolling plates into the cylindrical form, preparatory<br />

to riveting them up into shells, it is customary to bend one end of the plate to what is<br />

judged to be the proper radius, by the use of the sledge-hammer. <strong>The</strong> plate is then run<br />

through the rolls and rolled into shape, the end that was previously bent being introduced<br />

first. When the plate has been rolled all but the last five or six inches, the last<br />

end slips off of the first roll, and the rolls can no longer "grip" the sheet. <strong>The</strong> result<br />

is, that the last end of the sheet is not bent to the proper radius, but remains straight or