The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

18 THE LOCOMOTIVE, [Februaky,<br />

strength from 60° to 400° ; but an increase of heat from that point to a dull red heat<br />

shows a considerable reduction of strength and a great increase of ductility, the plates<br />

being in the ratio of 20.3 to 15.5 tons per square inch, as regards strength, and the rivet<br />

iron as 35 to 16. <strong>The</strong> iron suffers little or no diminution in its powers of resistance up<br />

to a temperature of 500° Fah."<br />

Next in order, after Fairbairn's experiments, came those made by the British Admiralty<br />

at the Portsmouth (Eng.) dock-yard, in 1877. <strong>The</strong> specimens to be tested were<br />

heated in an oil bath, and " the dies for gripping them were also so heated. <strong>The</strong> pro-<br />

cess of fixing and breaking occupied about one minute, during which care was taken to<br />

prevent, as far as possible, loss of heat by radiation and conduction." <strong>The</strong> temperature<br />

of each test-piece was recorded as equal to the temperature of the bath in which it was<br />

heated. Owing to the cooling of the specimens, and the suddenness with which they<br />

had to be pulled apart in order to compress the whole experiment into one minute, we<br />

cannot consider this series of tests to be very satisfactory, although it made an acceptable<br />

addition to what was then a very meagre knowledge of the effect of temperature on<br />

the strength of iron. <strong>The</strong> general conclusions that were reached by the committee hav-<br />

ing charge of these tests were as follows: " Wrought-irons, Yorkshire and re-manu-<br />

factured, increase in strength up to 500°, but lose slightly in ductility up to 300°, after<br />

which the ductility increases up to 500°, at which point it is still less than at the ordi-<br />

nary temperature of the air. <strong>The</strong> strength of Landore steel is not affected by tempera-<br />

ture up to 500°, but its ductility is reduced more than one-half."<br />

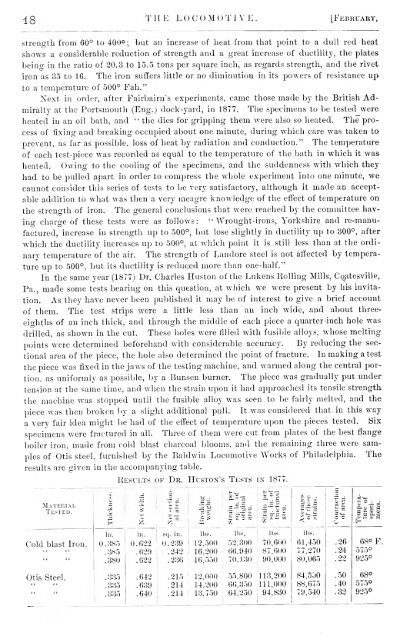

In the same year (1877) Dr. Charles Huston of the Lukens Rolling Mills, Cc^tesville,<br />

Pa., made some tests bearing on this question, at which we were present by his invita-<br />

tion. As they have never been published it may be of interest to give a brief account<br />

of them. <strong>The</strong> test strips were a little less than an inch wide, and about threeeighths<br />

of an inch thick, and through the middle of each piece a quarter-inch hole was<br />

drilled, as shown in the cut. <strong>The</strong>se holes were tilled with fusible alloys, whose melting<br />

points were determined beforehand with considerable accuracy. By reducing the sec-<br />

tional area of the piece, the hole also determined the point of fracture. In making a test<br />

the piece was fixed in the jaws of the testing machine, and warmed along the central portion,<br />

as uniformly as possible, by a Bunsen burner. <strong>The</strong> piece was gradually put under<br />

tension at the same time, and when the strain upon it had approached its tensile strength<br />

the machine was stopped until the fusible alloy was seen to be fairly melted, and the<br />

piece was then broken by a slight additional pull. It was considered that in this way<br />

a very fair idea might be had of the effect of temperature upon the pieces tested. Six<br />

specimens were fractured in all. Three of them were cut from plates of the best flange<br />

boiler iron, made from cold blast charcoal blooms, and the remaining three were samples<br />

of Otis steel, furnished by the Baldwin <strong>Locomotive</strong> Works of Philadelphia. <strong>The</strong><br />

results are given in the accompanying table.<br />

Material<br />

Tested.<br />

Results of Dr. Huston's Tests in 1877.