Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>Training</str<strong>on</strong>g> <str<strong>on</strong>g>Manual</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> <strong>Efficiency</strong> for Small and Medium Enterprises<br />

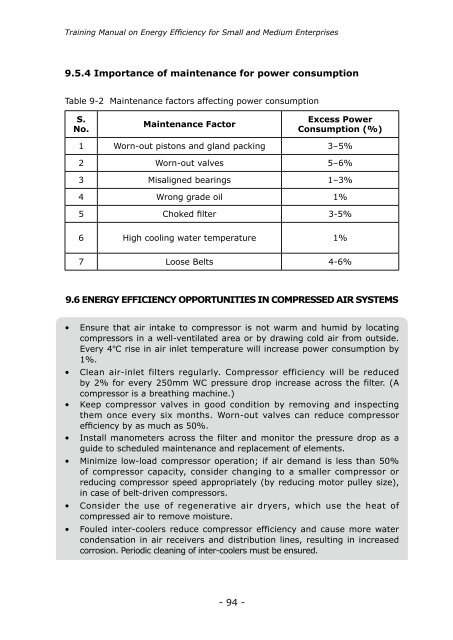

9.5.4 Importance of maintenance for power c<strong>on</strong>sumpti<strong>on</strong><br />

Table 9-2 Maintenance factors affecting power c<strong>on</strong>sumpti<strong>on</strong><br />

S.<br />

No.<br />

Maintenance Factor<br />

- 94 -<br />

Excess Power<br />

C<strong>on</strong>sumpti<strong>on</strong> (%)<br />

1 Worn-out pist<strong>on</strong>s and gland packing 3–5%<br />

2 Worn-out valves 5–6%<br />

3 Misaligned bearings 1–3%<br />

4 Wr<strong>on</strong>g grade oil 1%<br />

5 Choked filter 3-5%<br />

6 High cooling water temperature 1%<br />

7 Loose Belts 4-6%<br />

9.6 ENERGY EFFICIENCY OPPORTUNITIES IN COMPRESSED AIR SYSTEMS<br />

• Ensure that air intake to compressor is not warm and humid by locating<br />

compressors in a well-ventilated area or by drawing cold air from outside.<br />

Every 4 º C rise in air inlet temperature will increase power c<strong>on</strong>sumpti<strong>on</strong> by<br />

1%.<br />

• Clean air-inlet filters regularly. Compressor efficiency will be reduced<br />

by 2% for every 250mm WC pressure drop increase across the filter. (A<br />

compressor is a breathing machine.)<br />

• Keep compressor valves in good c<strong>on</strong>diti<strong>on</strong> by removing and inspecting<br />

them <strong>on</strong>ce every six m<strong>on</strong>ths. Worn-out valves can reduce compressor<br />

efficiency by as much as 50%.<br />

• Install manometers across the filter and m<strong>on</strong>itor the pressure drop as a<br />

guide to scheduled maintenance and replacement of elements.<br />

• Minimize low-load compressor operati<strong>on</strong>; if air demand is less than 50%<br />

of compressor capacity, c<strong>on</strong>sider changing to a smaller compressor or<br />

reducing compressor speed appropriately (by reducing motor pulley size),<br />

in case of belt-driven compressors.<br />

• C<strong>on</strong>sider the use of regenerative air dryers, which use the heat of<br />

compressed air to remove moisture.<br />

• Fouled inter-coolers reduce compressor efficiency and cause more water<br />

c<strong>on</strong>densati<strong>on</strong> in air receivers and distributi<strong>on</strong> lines, resulting in increased<br />

corrosi<strong>on</strong>. Periodic cleaning of inter-coolers must be ensured.