Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<str<strong>on</strong>g>Training</str<strong>on</strong>g> <str<strong>on</strong>g>Manual</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> <strong>Efficiency</strong> for Small and Medium Enterprises<br />

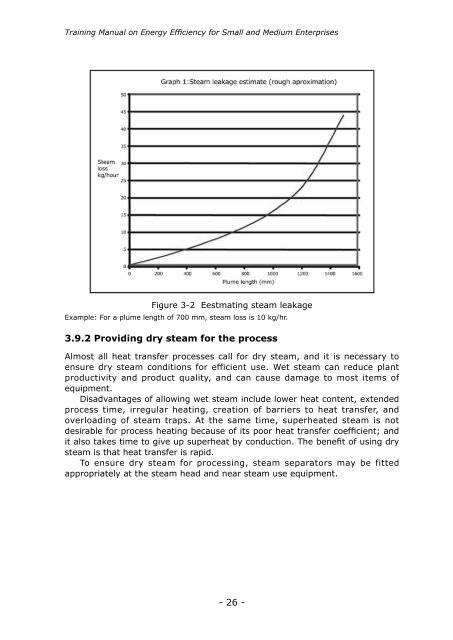

Figure 3-2 Eestmating steam leakage<br />

Example: For a plume length of 700 mm, steam loss is 10 kg/hr.<br />

3.9.2 Providing dry steam for the process<br />

Almost all heat transfer processes call for dry steam, and it is necessary to<br />

ensure dry steam c<strong>on</strong>diti<strong>on</strong>s for efficient use. Wet steam can reduce plant<br />

productivity and product quality, and can cause damage to most items of<br />

equipment.<br />

Disadvantages of allowing wet steam include lower heat c<strong>on</strong>tent, extended<br />

process time, irregular heating, creati<strong>on</strong> of barriers to heat transfer, and<br />

overloading of steam traps. At the same time, superheated steam is not<br />

desirable for process heating because of its poor heat transfer coefficient; and<br />

it also takes time to give up superheat by c<strong>on</strong>ducti<strong>on</strong>. The benefit of using dry<br />

steam is that heat transfer is rapid.<br />

To ensure dry steam for processing, steam separators may be fitted<br />

appropriately at the steam head and near steam use equipment.<br />

- 26 -