Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

- 7 -<br />

Fuels and Combusti<strong>on</strong><br />

the burner tip, possibly extinguishing the flame and reducing the flame<br />

temperature or lengthening the flame.<br />

1.4.4 Pre-heating of fuel oil for pumping<br />

Pre-heating oil in storage may be needed to make it less viscous and easily<br />

pumpable.<br />

Heating an entire oil tank or outflow heater may be needed to heat oil<br />

which is to be pumped away. Outflow heaters with steam or electricity are also<br />

used often to ensure smooth pumping.<br />

1.4.5 Pre-heating requirements for oil combusti<strong>on</strong><br />

For pre-heating of oil, in-line heaters are to be used to raise oil temperature<br />

from pumping to combusti<strong>on</strong> temperature. In-line heaters are of either<br />

electrical or steam tracing type. The pre-heat temperatures of oil are<br />

determined by the viscosity of oil supplied at room temperature and the<br />

recommended viscosity at the burner tip.<br />

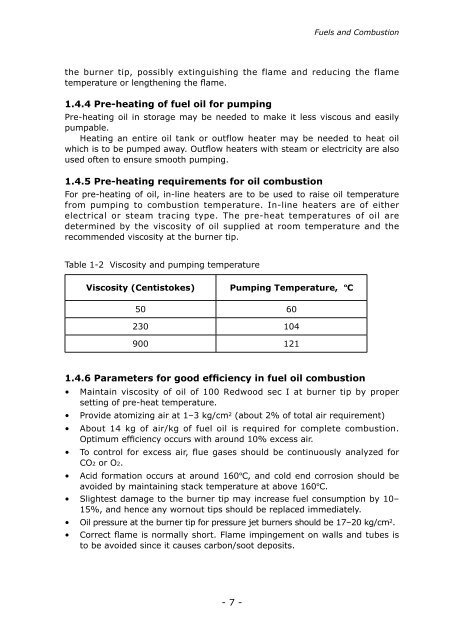

Table 1-2 Viscosity and pumping temperature<br />

Viscosity (Centistokes) Pumping Temperature, ºC<br />

50 60<br />

230 104<br />

900 121<br />

1.4.6 Parameters for good efficiency in fuel oil combusti<strong>on</strong><br />

• Maintain viscosity of oil of 100 Redwood sec I at burner tip by proper<br />

setting of pre-heat temperature.<br />

• Provide atomizing air at 1–3 kg/cm 2 (about 2% of total air requirement)<br />

• About 14 kg of air/kg of fuel oil is required for complete combusti<strong>on</strong>.<br />

Optimum efficiency occurs with around 10% excess air.<br />

• To c<strong>on</strong>trol for excess air, flue gases should be c<strong>on</strong>tinuously analyzed for<br />

CO2 or O2.<br />

• Acid formati<strong>on</strong> occurs at around 160 ºC, and cold end corrosi<strong>on</strong> should be<br />

avoided by maintaining stack temperature at above 160 ºC.<br />

• Slightest damage to the burner tip may increase fuel c<strong>on</strong>sumpti<strong>on</strong> by 10–<br />

15%, and hence any wornout tips should be replaced immediately.<br />

• Oil pressure at the burner tip for pressure jet burners should be 17–20 kg/cm 2 .<br />

• Correct flame is normally short. Flame impingement <strong>on</strong> walls and tubes is<br />

to be avoided since it causes carb<strong>on</strong>/soot deposits.