Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.3 LOAD MANAGEMENT STRATEGIES<br />

5.3.1 Rescheduling and staggering loads<br />

- 49 -<br />

Electrical Load Management<br />

the MD recorder will be computing MD for the durati<strong>on</strong> of 30 minutes as:<br />

(2500 x 4) + (3600 x 12) + (4100 x 6) + (3800 x 8)<br />

= 3606.7 kVA<br />

30<br />

Various techniques applicable to optimize maximum demand of an industry<br />

include:<br />

• Rescheduling loads;<br />

• Staggering of motor loads;<br />

• Storage of products/in process material/process utilities like refrigerati<strong>on</strong>;<br />

• Shedding of n<strong>on</strong>-essential loads;<br />

• Operati<strong>on</strong> of captive power generati<strong>on</strong>; and<br />

• Reactive power compensati<strong>on</strong>.<br />

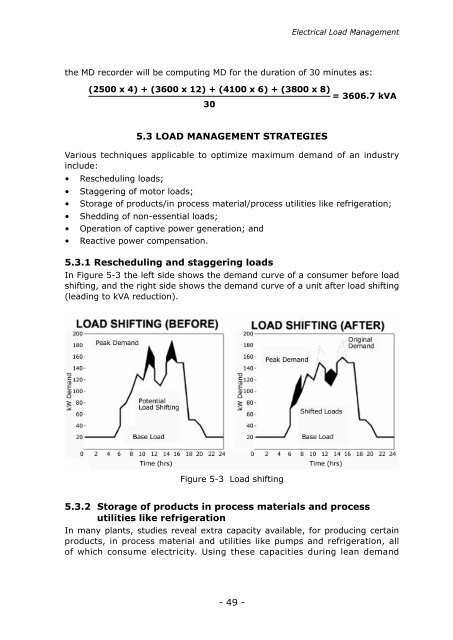

In Figure 5-3 the left side shows the demand curve of a c<strong>on</strong>sumer before load<br />

shifting, and the right side shows the demand curve of a unit after load shifting<br />

(leading to kVA reducti<strong>on</strong>).<br />

Figure 5-3 Load shifting<br />

5.3.2 Storage of products in process materials and process<br />

utilities like refrigerati<strong>on</strong><br />

In many plants, studies reveal extra capacity available, for producing certain<br />

products, in process material and utilities like pumps and refrigerati<strong>on</strong>, all<br />

of which c<strong>on</strong>sume electricity. Using these capacities during lean demand