Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>Training</str<strong>on</strong>g> <str<strong>on</strong>g>Manual</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> <strong>Efficiency</strong> for Small and Medium Enterprises<br />

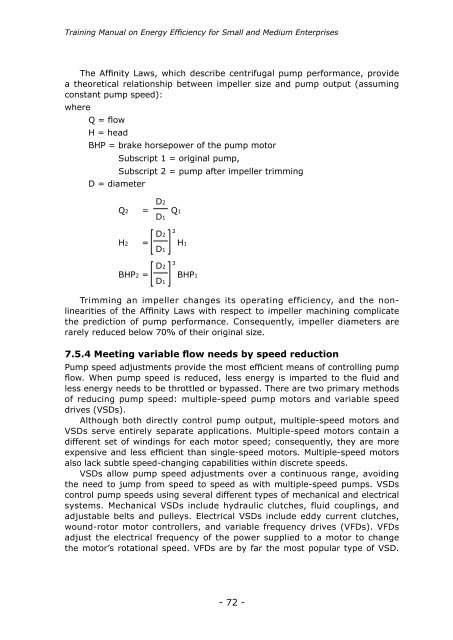

The Affinity Laws, which describe centrifugal pump performance, provide<br />

a theoretical relati<strong>on</strong>ship between impeller size and pump output (assuming<br />

c<strong>on</strong>stant pump speed):<br />

where<br />

Q = flow<br />

H = head<br />

BHP = brake horsepower of the pump motor<br />

D = diameter<br />

Subscript 1 = original pump,<br />

Subscript 2 = pump after impeller trimming<br />

Q2 =<br />

H2 =<br />

BHP2 =<br />

D2<br />

D1<br />

D2<br />

D1<br />

D2<br />

D1<br />

Q1<br />

2<br />

3<br />

H1<br />

BHP1<br />

Trimming an impeller changes its operating efficiency, and the n<strong>on</strong>linearities<br />

of the Affinity Laws with respect to impeller machining complicate<br />

the predicti<strong>on</strong> of pump performance. C<strong>on</strong>sequently, impeller diameters are<br />

rarely reduced below 70% of their original size.<br />

7.5.4 Meeting variable flow needs by speed reducti<strong>on</strong><br />

Pump speed adjustments provide the most efficient means of c<strong>on</strong>trolling pump<br />

flow. When pump speed is reduced, less energy is imparted to the fluid and<br />

less energy needs to be throttled or bypassed. There are two primary methods<br />

of reducing pump speed: multiple-speed pump motors and variable speed<br />

drives (VSDs).<br />

Although both directly c<strong>on</strong>trol pump output, multiple-speed motors and<br />

VSDs serve entirely separate applicati<strong>on</strong>s. Multiple-speed motors c<strong>on</strong>tain a<br />

different set of windings for each motor speed; c<strong>on</strong>sequently, they are more<br />

expensive and less efficient than single-speed motors. Multiple-speed motors<br />

also lack subtle speed-changing capabilities within discrete speeds.<br />

VSDs allow pump speed adjustments over a c<strong>on</strong>tinuous range, avoiding<br />

the need to jump from speed to speed as with multiple-speed pumps. VSDs<br />

c<strong>on</strong>trol pump speeds using several different types of mechanical and electrical<br />

systems. Mechanical VSDs include hydraulic clutches, fluid couplings, and<br />

adjustable belts and pulleys. Electrical VSDs include eddy current clutches,<br />

wound-rotor motor c<strong>on</strong>trollers, and variable frequency drives (VFDs). VFDs<br />

adjust the electrical frequency of the power supplied to a motor to change<br />

the motor’s rotati<strong>on</strong>al speed. VFDs are by far the most popular type of VSD.<br />

- 72 -