Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<str<strong>on</strong>g>Training</str<strong>on</strong>g> <str<strong>on</strong>g>Manual</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> <strong>Efficiency</strong> for Small and Medium Enterprises<br />

10.5 OPERATIONAL FACTORS AFFECTING PERFORMANCE AND<br />

ENERGY EFFICIENCY OF REFRIGERATION PLANTS<br />

10.5.1 Design of process heat exchangers<br />

There is a tendency with most of the process units to operate with high<br />

safety margins, which influences the compressor sucti<strong>on</strong> pressure/evaporator<br />

set point. For instance, a process cooling requirement of 15 º C would need<br />

chilled water at a lower temperature, but the coolant temperature range<br />

can vary from 6 º C to perhaps 10 º C. At 10 º C chilled water temperature, the<br />

refrigerant side temperature has to be lower, perhaps –5 º C to +5 º C. The<br />

refrigerant temperature again sets the corresp<strong>on</strong>ding sucti<strong>on</strong> pressure of the<br />

refrigerant, which determines the inlet duty c<strong>on</strong>diti<strong>on</strong>s for work of compressi<strong>on</strong><br />

of the refrigerant compressor. Having the optimum/minimum driving force<br />

(temperature difference) can, thus, help to achieve the highest possible sucti<strong>on</strong><br />

pressure at the compressor, thereby leading to lower energy requirements.<br />

This requires proper sizing of heat transfer areas of process heat exchangers<br />

and evaporators as well as rati<strong>on</strong>alizing the temperature requirement to<br />

highest possible value. A 1 º C raise in evaporator temperature can help to save<br />

almost 3% <strong>on</strong> power c<strong>on</strong>sumpti<strong>on</strong>. The TR capacity of the same machine will<br />

also increase with the evaporator temperature, as given in Table 10-1.<br />

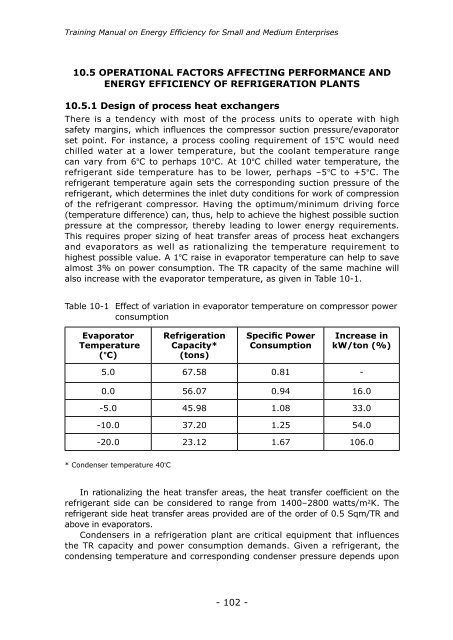

Table 10-1 Effect of variati<strong>on</strong> in evaporator temperature <strong>on</strong> compressor power<br />

c<strong>on</strong>sumpti<strong>on</strong><br />

Evaporator<br />

Temperature<br />

( º C)<br />

Refrigerati<strong>on</strong><br />

Capacity*<br />

(t<strong>on</strong>s)<br />

- 102 -<br />

Specific Power<br />

C<strong>on</strong>sumpti<strong>on</strong><br />

Increase in<br />

kW/t<strong>on</strong> (%)<br />

5.0 67.58 0.81 -<br />

0.0 56.07 0.94 16.0<br />

-5.0 45.98 1.08 33.0<br />

-10.0 37.20 1.25 54.0<br />

-20.0 23.12 1.67 106.0<br />

* C<strong>on</strong>denser temperature 40 º C<br />

In rati<strong>on</strong>alizing the heat transfer areas, the heat transfer coefficient <strong>on</strong> the<br />

refrigerant side can be c<strong>on</strong>sidered to range from 1400–2800 watts/m 2 K. The<br />

refrigerant side heat transfer areas provided are of the order of 0.5 Sqm/TR and<br />

above in evaporators.<br />

C<strong>on</strong>densers in a refrigerati<strong>on</strong> plant are critical equipment that influences<br />

the TR capacity and power c<strong>on</strong>sumpti<strong>on</strong> demands. Given a refrigerant, the<br />

c<strong>on</strong>densing temperature and corresp<strong>on</strong>ding c<strong>on</strong>denser pressure depends up<strong>on</strong>