Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

Training Manual on Energy Efficiency - APO Asian Productivity ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Table 4-1 Radiant heat loss comparis<strong>on</strong> at various temperatures<br />

C1<br />

( º C)<br />

C2<br />

( º C)<br />

K1<br />

(C1 +273)<br />

K2<br />

(C2 +273)<br />

- 37 -<br />

(K1/K2) 4<br />

Relative<br />

Radiant Heat Transfer<br />

700 20 973 293 122 1.0 (baseline value)<br />

900 20 1173 293 255 2.1<br />

1100 20 1373 293 482 3.96<br />

1300 20 1573 293 830 6.83<br />

1500 20 1773 293 1340 11.02<br />

1700 20 1973 293 2056 16.91<br />

(Note: C1 is hot body temperature and C2 is ambient air temperature)<br />

<strong>Energy</strong> <strong>Efficiency</strong> in Furnaces<br />

In other words, the radiati<strong>on</strong> losses from an open furnace door at 1500 º C<br />

are 11 times greater than the losses of the same furnace at 700 º C. A good<br />

practice for ir<strong>on</strong> and steel melters is to keep the furnace lid closed at all times<br />

and maintain a c<strong>on</strong>tinuous feed of cold charge <strong>on</strong>to the molten bath.<br />

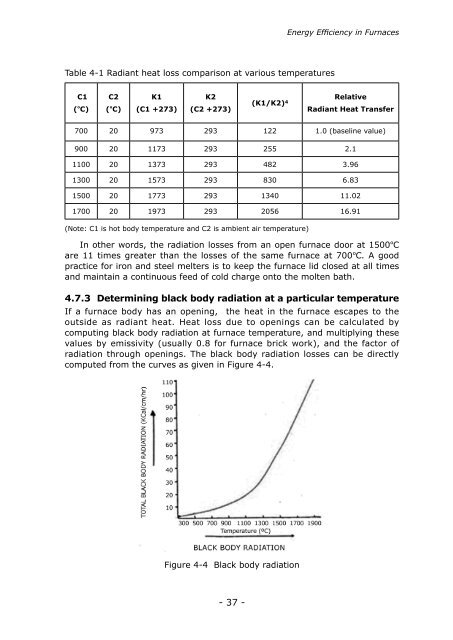

4.7.3 Determining black body radiati<strong>on</strong> at a particular temperature<br />

If a furnace body has an opening, the heat in the furnace escapes to the<br />

outside as radiant heat. Heat loss due to openings can be calculated by<br />

computing black body radiati<strong>on</strong> at furnace temperature, and multiplying these<br />

values by emissivity (usually 0.8 for furnace brick work), and the factor of<br />

radiati<strong>on</strong> through openings. The black body radiati<strong>on</strong> losses can be directly<br />

computed from the curves as given in Figure 4-4.<br />

Figure 4-4 Black body radiati<strong>on</strong>