The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

She jfttotmrtttre*<br />

PUBLISHED BY THE HARTFORD STEAM BOILER INSPECTION AND INSURA COMPANY.<br />

Vol. XXII. HARTFORD, CONN., JULY, 1901. /, No. Tf<br />

Concerning' Pressed Steel Braces.<br />

In the May issue of <strong>The</strong> <strong>Locomotive</strong> we printed an article entitled "A Common<br />

Defect in Bracing," in which we drew attention to the fact that it is by no means uncommon<br />

for boiler makers to provide adequate strength in the body of a brace, while<br />

leaving the blade, or part by which the brace is secured to the shell, altogether too<br />

weak across the line where the first rivet hole comes.<br />

<strong>The</strong> article in question aroused a great deal of interest, if we may judge by the<br />

considerable correspondence that it has called out ; and for this reason we desire to<br />

supplement it by a few more remarks on the same subject. In the previous article, we<br />

discussed only the solid type of brace, which is forged up out of round iron. <strong>The</strong> so-<br />

called " formed braces," which are stamped or pressed into shape out of sheet metal, are<br />

coming more and more into favor, in place of the forged kind, both because they are<br />

cheaper, and because they have no weld. We desire to call attention, however, to the<br />

fact that the formed braces are also liable to the same defect that we have already indi-<br />

cated in connection with the solid ones.<br />

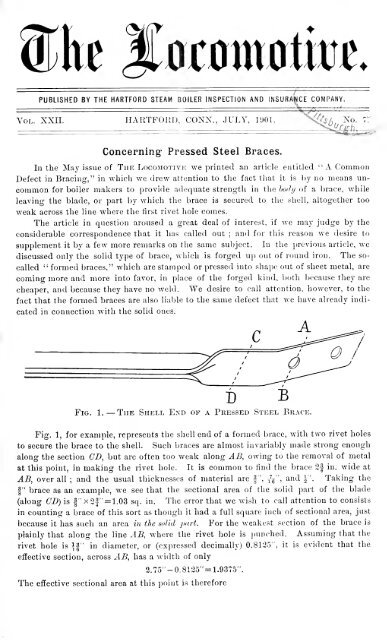

Fig. 1.<br />

—<br />

D<br />

B<br />

<strong>The</strong> Shell End of a Pressed Steel Brace.<br />

Fig. 1, for example, represents the shell end of a formed brace, with two rivet holes<br />

to secure the brace to the shell. Such braces are almost invariably made strong enough<br />

along the section CD, but are often too weak along AB, owing to the removal of metal<br />

at this point, in making the rivet hole. It is common to find the brace 2f in. wide at<br />

AB, over all ; and the usual thicknesses of material are §", T 7<br />

5 ", and J". Taking the<br />

|" brace as an example, we see that the sectional area of the solid part of the blade<br />

(aloug CD) is |" x 2f " = 1.03 sq. in. <strong>The</strong> error that we wish to call attention to consists<br />

in counting a brace of this sort as though it had a full square inch of sectional area, just<br />

because it has such an area in the solid part. For the weakest section of the brace is<br />

plainly that along the line AB, where the rivet hole is punched. Assuming that the<br />

rivet hole is f§" i Q diameter, or (expressed decimally) 0.8125", it is evident that the<br />

effective section, across AB, has a width of only<br />

2.75"-0.8125" = 1.9375".<br />

<strong>The</strong> effective sectional area at this point is therefore