The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1901.] THE LOCOMOTIVE, 51<br />

case, in which the cock is closed instantaneously; and this will give us some idea, at<br />

least, of the forces that are in operation in the actual case.<br />

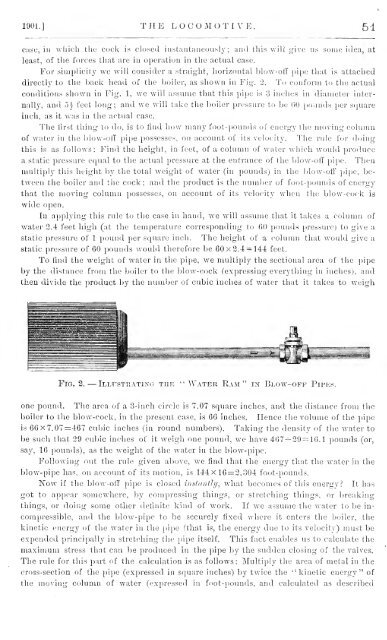

For simplicity we will consider a straight, horizontal blow-off pipe that is attached<br />

directly to the back head of the boiler, as shown in Fig. 2. To conform to the actual<br />

conditions shown in Fig. 1, we will assume that this pipe is 3 inches in diameter inter-<br />

nally, and o£ feet long; and we will take the boiler pressure to be GO pounds per square<br />

inch, as it was in the actual case.<br />

<strong>The</strong> first thing to do, is to find how many foot-pounds of energy the moving column<br />

of water in the blow-off pipe possesses, on account of its velocity. <strong>The</strong> rule for doing<br />

this is as follows: Find the height, in feet, of a column of water which would produce<br />

a static pressure equal to the actual pressure at the entrance of the blow-off pipe. <strong>The</strong>n<br />

multiply this height by the total weight of water (in pounds) in the blow-oft' pipe, be-<br />

tween the boiler and the cock; and the product is the number of foot-pounds of energy<br />

that the moving column possesses, on account of its velocity when the blow-cock is<br />

wide open.<br />

In applying this rule to the case in hand, we will assume that it takes a column of<br />

water 2.4 feet high (at the temperature corresponding to 60 pounds pressure) to give a<br />

static pressure of 1 pound per square inch. <strong>The</strong> height of a column that would give a<br />

static pressure of 60 pounds would therefore be 60x2.4 = 144 feet.<br />

To find the weight of water in the pipe, we multiply the sectional area of the pipe<br />

by the distance from the boiler to the blow-cock (expressing everything in inches), and<br />

then divide the product by the number of cubic inches of water that it takes to weigh<br />

Fig. 2.<br />

—<br />

Illustrating the ""Water Ram" in Blow-off Pipes.<br />

one pound. <strong>The</strong> area of a 3-inch circle is 7.07 square inches, and the distance from the<br />

boiler to the blow-cock, in the present case, is 66 inches. Hence the volume of the pipe<br />

is 66x7.07=467 cubic inches (in round numbers). Taking the density of the water to<br />

be such that 29 cubic inches of it weigh one pound, we have 467-^-29 = 16.1 pounds (or,<br />

say, 16 pounds), as the weight of the water in the blow-pipe.<br />

Following out the rule given above, we find that the energy that the water in the<br />

blow-pipe has, on account of its motion, is 144x16 = 2,304 foot-pounds.<br />

Now if the blow-off pipe is closed instantly, what becomes of this energy? It has<br />

got to appear somewhere, by compressing things, or stretching things, or breaking<br />

things, or doing some other definite kind of work. If we assume the water to be in-<br />

compressible, and the blow-pipe to be securely fixed where it enters the boiler, the<br />

kinetic energy of the water in the pipe (that is, the energy due to its velocity) must be<br />

expended principally in stretching the pipe itself. This fact enables us to calculate the<br />

maximum stress that can be produced in the pipe by the sudden closing of the valves.<br />

<strong>The</strong> rule for this part of the calculation is as follows: Multiply the area of metal in the<br />

cross-section of the pipe (expressed in square inches) by twice the "kinetic energy" of<br />

the moving column of water (expressed in foot-pounds, and calculated as described