Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.1.2 The skin<br />

One of two basic types of skins covers the hull and deck structure, providing a<br />

watertight membrane. Variations of planking provided the only alternatives for<br />

covering wooden structures for thousands of years until modern adhesives made the<br />

plywood skin more common and more durable.<br />

Planking<br />

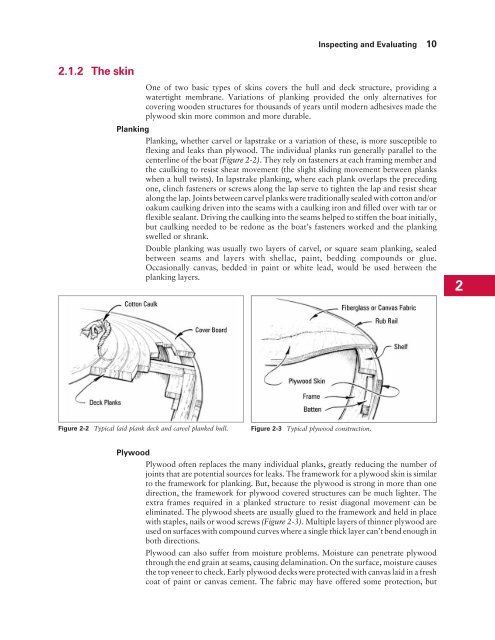

Planking, whether carvel or lapstrake or a variation of these, is more susceptible to<br />

flexing and leaks than plywood. The individual planks run generally parallel to the<br />

centerline of the boat (Figure 2-2). They rely on fasteners at each framing member and<br />

the caulking to resist shear movement (the slight sliding movement between planks<br />

when a hull twists). In lapstrake planking, where each plank overlaps the preceding<br />

one, clinch fasteners or screws along the lap serve to tighten the lap and resist shear<br />

along the lap. Joints between carvel planks were traditionally sealed with cotton and/or<br />

oakum caulking driven into the seams with a caulking iron and filled over with tar or<br />

flexible sealant. Driving the caulking into the seams helped to stiffen the boat initially,<br />

but caulking needed to be redone as the boat’s fasteners worked and the planking<br />

swelled or shrank.<br />

Double planking was usually two layers of carvel, or square seam planking, sealed<br />

between seams and layers with shellac, paint, bedding compounds or glue.<br />

Occasionally canvas, bedded in paint or white lead, would be used between the<br />

planking layers.<br />

Figure 2-2 Typical laid plank deck and carvel planked hull. Figure 2-3 Typical plywood construction.<br />

Inspecting and Evaluating 10<br />

Plywood<br />

Plywood often replaces the many individual planks, greatly reducing the number of<br />

joints that are potential sources for leaks. The framework for a plywood skin is similar<br />

to the framework for planking. But, because the plywood is strong in more than one<br />

direction, the framework for plywood covered structures can be much lighter. The<br />

extra frames required in a planked structure to resist diagonal movement can be<br />

eliminated. The plywood sheets are usually glued to the framework and held in place<br />

with staples, nails or wood screws (Figure 2-3). Multiple layers of thinner plywood are<br />

used on surfaces with compound curves where a single thick layer can’t bend enough in<br />

both directions.<br />

Plywood can also suffer from moisture problems. Moisture can penetrate plywood<br />

through the end grain at seams, causing delamination. On the surface, moisture causes<br />

the top veneer to check. Early plywood decks were protected with canvas laid in a fresh<br />

coat of paint or canvas cement. The fabric may have offered some protection, but<br />

2