Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4.1.1 Laminating in a jig<br />

springback in the curved frame. Using more, thinner strips results in a curved frame<br />

with greater strength and less springback, but requires more labor and epoxy to build.<br />

Use thinner strips especially with harder woods like white oak.<br />

3. Use full-length strips. Make the strips longer than the finished frame to allow for<br />

trimming.<br />

4. The new frame width should be the same as the original frame. Strips can be wider to<br />

allow for trimming and finishing after the frame is laid up.<br />

5. Select wood strips that are seasoned. Ideal moisture content is 6% to 14%.<br />

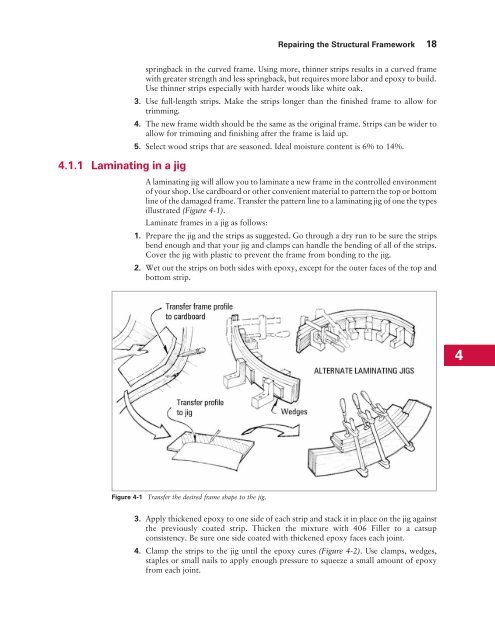

A laminating jig will allow you to laminate a new frame in the controlled environment<br />

of your shop. Use cardboard or other convenient material to pattern the top or bottom<br />

line of the damaged frame. Transfer the pattern line to a laminating jig of one the types<br />

illustrated (Figure 4-1).<br />

Laminate frames in a jig as follows:<br />

1. Prepare the jig and the strips as suggested. Go through a dry run to be sure the strips<br />

bend enough and that your jig and clamps can handle the bending of all of the strips.<br />

Cover the jig with plastic to prevent the frame from bonding to the jig.<br />

2. Wet out the strips on both sides with epoxy, except for the outer faces of the top and<br />

bottom strip.<br />

Figure 4-1 Transfer the desired frame shape to the jig.<br />

<strong>Repair</strong>ing the Structural Framework 18<br />

3. Apply thickened epoxy to one side of each strip and stack it in place on the jig against<br />

the previously coated strip. Thicken the mixture with 406 Filler to a catsup<br />

consistency. Be sure one side coated with thickened epoxy faces each joint.<br />

4. Clamp the strips to the jig until the epoxy cures (Figure 4-2). Use clamps, wedges,<br />

staples or small nails to apply enough pressure to squeeze a small amount of epoxy<br />

from each joint.<br />

4